Coal mining machinery forgings: The "hardcore confidence" for efficient coal mining, the core components all rely on them to withstand extreme working conditions!

Coal mining machinery forgings: The "hardcore confidence" for efficient coal mining, the core components all rely on them to withstand extreme working conditions!

Under the trend of intelligent and deep mining in coal mines, coal mining equipment needs to withstand extreme tests such as high humidity, high dust, strong impact and heavy load friction underground for a long time. As the "strength core" of coal mining machinery equipment, forgings, with their dense internal structure and excellent wear resistance and fatigue resistance, have become the core manufacturing choice for key equipment such as coal mining machines, roadheaders, and hydraulic supports. Many coal mining enterprises and equipment purchasers are puzzled: In which core parts are coal mining machine forgings specifically used? Why can high-quality forgings directly enhance mining efficiency? How to select forging products suitable for underground working conditions? This article will comprehensively disassemble the core value of coal mining machinery forgings from three dimensions: application scenarios, process advantages, and selection guidelines for you.

I. Coal Mining Machinery Forgings: The "Core Load-bearing Components" Running through the Entire Process

From coal mining, tunneling to transportation, every key link in coal mining cannot do without the stable support of forgings. These precisely forged components are the "key handles" for coal mining equipment to cope with harsh working conditions:

The core of the coal mining machine: cutting teeth, main shaft forgings

The cutting teeth are the key to the "coal biting" of the coal shearer and need to withstand severe impact and wear resistance tests. Forged picks are made of high-strength alloy steel through die forging and surface strengthening treatment. Their hardness can reach over HRC60, and their service life is more than twice that of ordinary cast picks, which can reduce the downtime losses caused by frequent replacement. The main shaft forging is the "power transmission shaft" of the coal mining machine. Through integral forging to eliminate internal defects, its tensile strength exceeds 800MPa, ensuring the stable transmission of motor power to the cutting section and capable of withstanding long-term heavy-load operation.

Key points of the tunnel boring machine: gear shafts, flange forgings

When a tunnel boring machine is excavating tunnels underground, it needs to withstand continuous vibration and shock. The gear shaft forgings adopt a stepped forging structure, precisely meeting the connection requirements of components of different sizes. Through a multi-tooth load sharing design, the transmission efficiency and stability are enhanced. Flange forgings serve as the "connecting links" for various components of the tunnel boring machine. Through the annular forging process, the flatness of the plane is guaranteed, ensuring that they do not loosen or leak oil under high-pressure conditions, and providing stable support for the overall operation of the equipment.

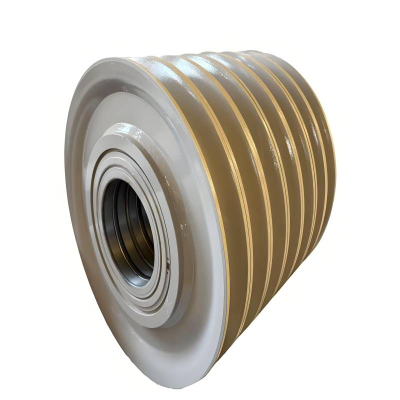

The core of the hydraulic support: column, jack piston rod forgings

Hydraulic supports are the "steel backbone" of underground support. The columns and jack piston rods need to bear huge support loads and frequent extension and contraction frictions. This type of forging is made by solid forging process and combined with quenching and tempering heat treatment. It not only has extremely high compressive strength but also can resist the high humidity corrosion underground through surface anti-corrosion treatment. Its service life directly determines the support safety and advancement efficiency of the working face. High-quality forgings can extend the fault-free working time of hydraulic supports to more than 12,000 hours.

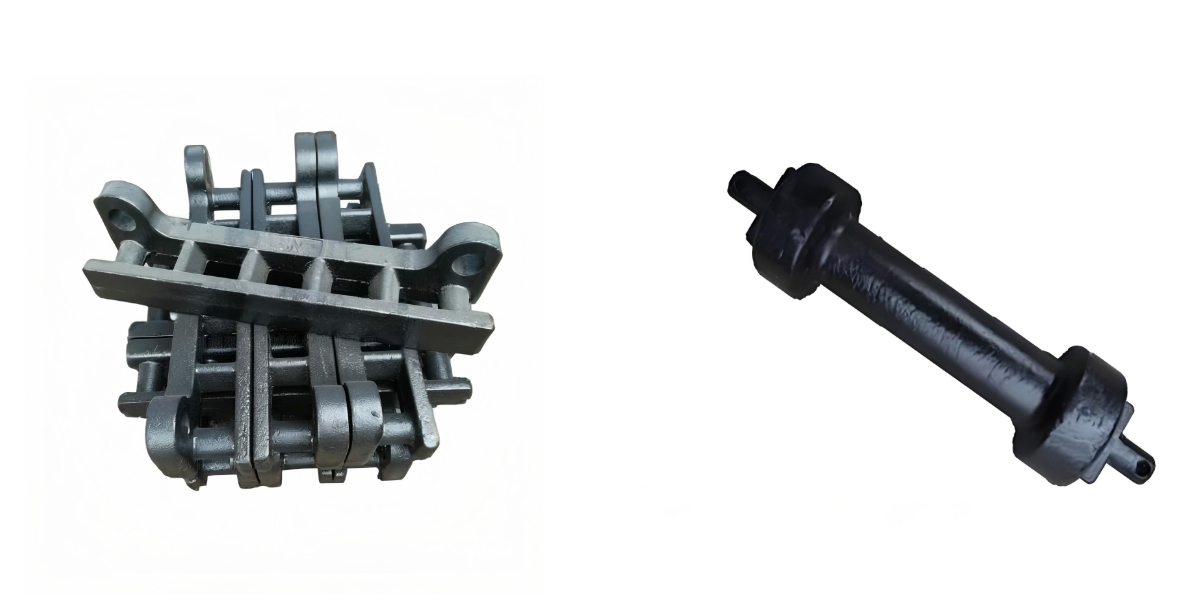

Key components of the conveying equipment: scraper, middle trough forgings

The scraper conveyor is the "lifeline" of coal transportation. The scraper and the middle trough need to withstand the continuous friction and heavy load pressure of the coal. The forged scraper has significantly enhanced its bending resistance and wear resistance by optimizing the flow direction of metal fibers. The middle trough forgings can be strengthened on the surface through plasma cladding technology, forming a high-strength wear-resistant layer, which increases the coal throughput by more than 30% and extends the service life by three times. In addition, the anchor chains, hooks and other auxiliary components for conveying are all forged products to ensure the safety and stability of heavy-load conveying.

Ii. Forging Process: The "Core Code" for Coal Mining Machinery Forgings to Adapt to Underground Working Conditions

The harshness of the underground working conditions determines that the components of coal mining machinery cannot be manufactured by ordinary processes. Forgings, with their unique technological advantages, have become the "preferred solution" for coal mining machinery equipment:

It has excellent strength and toughness, and can withstand extreme loads

The forging process involves pressing metal billets at high temperatures and pressures to break down coarse grains and make them densely arranged, completely eliminating common defects such as pores and sand holes in castings. The tensile strength and impact resistance of coal mining machinery forgings are 30% to 50% higher than those of castings. They can easily cope with extreme working conditions such as strong impact and heavy load underground, reducing the downtime caused by component fracture and deformation.

Wear-resistant and fatigue-resistant, reducing maintenance costs

In response to the high-friction and high-cyclic stress environment underground, the coal mining machinery forgings are made of high-quality alloy steel and undergo heat treatment processes such as carburizing and nitriding, significantly enhancing their surface hardness and wear resistance. For instance, the new type of bainitic steel forged wear-resistant liner has a service life of up to 180 days on semi-autogenous grinding machines, far exceeding the three months of traditional cast liners, significantly reducing the frequency of maintenance and replacement costs.

The size is precise and meets the assembly requirements

Precision die forging technology can achieve "near-net forming" of coal mining machinery forgings, with dimensional tolerances controlled within ±0.05mm. Only a small amount of fine processing is required subsequently to meet the assembly requirements. This high-precision feature ensures that the forgings fit perfectly with other components, avoiding increased vibration and wear caused by excessive clearance, and enhancing the operational stability of the entire machine.

Strong customization, suitable for diverse scenarios

The flexibility of the forging process can meet the customized requirements of different coal mining machinery: for the high-pressure environment of deep mining, high-strength pressure-resistant forgings can be customized. For high-humidity mines, corrosion-resistant alloy forgings can be selected. In response to the lightweight requirements of intelligent equipment, a hollow forged structure can be designed to reduce the self-weight of the equipment while ensuring its strength.

Iii. Guide to Selecting Coal Mining Machinery Forgings: 3 Core Points to Avoid Procurement Misunderstandings

For coal mining enterprises and equipment purchasers, choosing the right forgings is the key to ensuring mining efficiency and reducing safety risks. When purchasing, the following three points should be given special attention:

Verify the process and test report

Give priority to products made by die forging or free forging processes. Die forgings have stable performance, while free forging can reduce the production cost of large components. At the same time, the supplier is required to provide a complete inspection report, including material test reports and non-destructive testing reports (ultrasonic flaw detection, magnetic particle flaw detection), to ensure that the forgings have no internal cracks, inclusions or other defects.

Select the material and structure to match the working conditions

Select the appropriate type based on the usage scenario: For wear-resistant components such as picks and scrapers, give priority to alloy steel forgings with surface strengthening treatment. For pressure-bearing components such as hydraulic support columns, high-strength solid forgings with quenching and tempering treatment should be selected. The connecting components can be made of flange forgings or step forgings, taking into account both connection stability and assembly efficiency.

Pay attention to surface treatment and service data

In the high-humidity and high-corrosion environment underground, surface anti-corrosion treatment is of vital importance. It is necessary to confirm whether the forgings have undergone galvanization, anti-corrosion coating or plasma cladding and other treatments. At the same time, pay attention to the actual service data of the products, and give priority to choosing forgings that have successful application cases in similar mines to ensure that they are suitable for the actual mining conditions.

Iv. Industry Trends: Intelligent mining drives the upgrade of coal mining machinery forgings

With the accelerated advancement of intelligent transformation in coal mines, the market size of coal mining machinery forgings in China is expected to exceed 65 billion yuan by 2025, among which the application proportion of high-end alloy steel forgings will increase to over 45%. In the future, coal mining machinery forgings will develop towards super-large dimensions, precision and intelligence: Digital twin technology will be applied to the optimization of forging processes, reducing the defect rate of forgings to below 1.2%. The popularization of isothermal forging and precision die forging processes will further enhance the fatigue life and dimensional accuracy of forgings, contributing to cost reduction and efficiency improvement in coal mining.

Summary

Forgings are the "hardcore foundation" of coal mining equipment. From the cutting teeth of coal mining machines to the columns of hydraulic supports, the quality of each key forging directly affects the efficiency, safety and cost of coal mining. Driven by both deep mining and intelligent transformation, high-quality and suitable coal mining machinery forgings have become the key for coal mining enterprises to enhance their core competitiveness.

If you need to learn more about customized solutions for coal mining machinery forgings, cases of forgings suitable for different working conditions, or obtain industry standard comparison tables for coal mining machinery forgings, please feel free to contact us at any time! We will provide you with high-quality forging products that comply with coal mine safety regulations and professional technical support.