Crane Pulley Manufacturer

1.Material:Q355B\Q355D\Q550D\35#

2.Machining accuracy:±0.1mm

3.Mold opening cycle:About 30 days

4.Customization: We design and manufacture tailor-made products to your exact technical requirements.

5.Advantages:

Our strict process inspection ensures every product meets defect-free standards.

Streamlined one-stop processing delivers efficiency and cost savings.

From standard to custom, our wide product range solves all your needs.

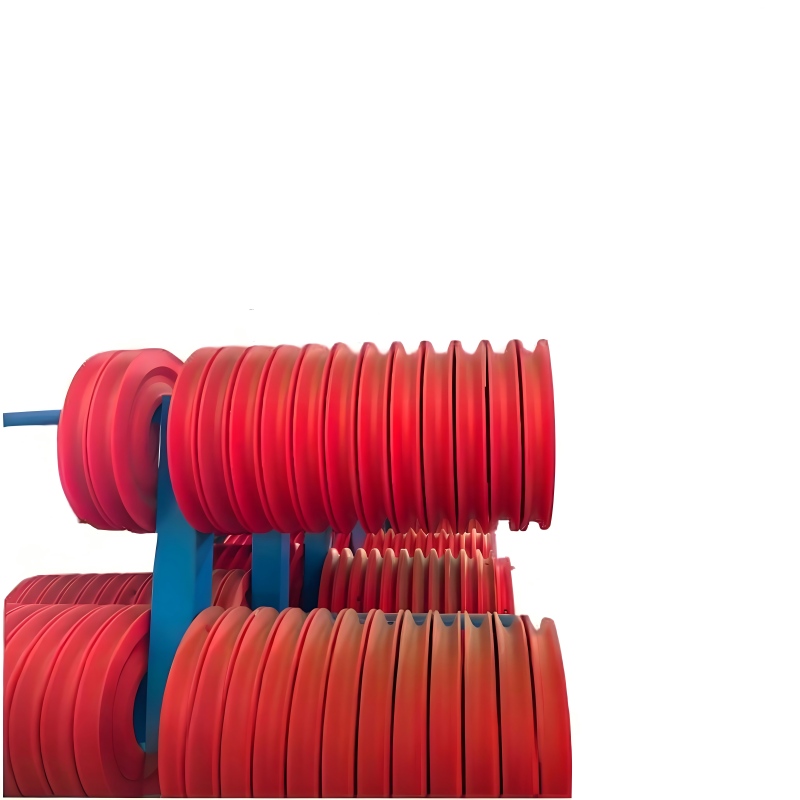

Product Introduction:

As a crucial transmission part of the hook assembly, the crane pulley changes the direction of force and lowers the energy consumption of hoisting through the application of the rolling friction principle. Functioning as a key component to enhance hoisting efficiency and stability, it is an essential element in numerous types of lifting equipment.

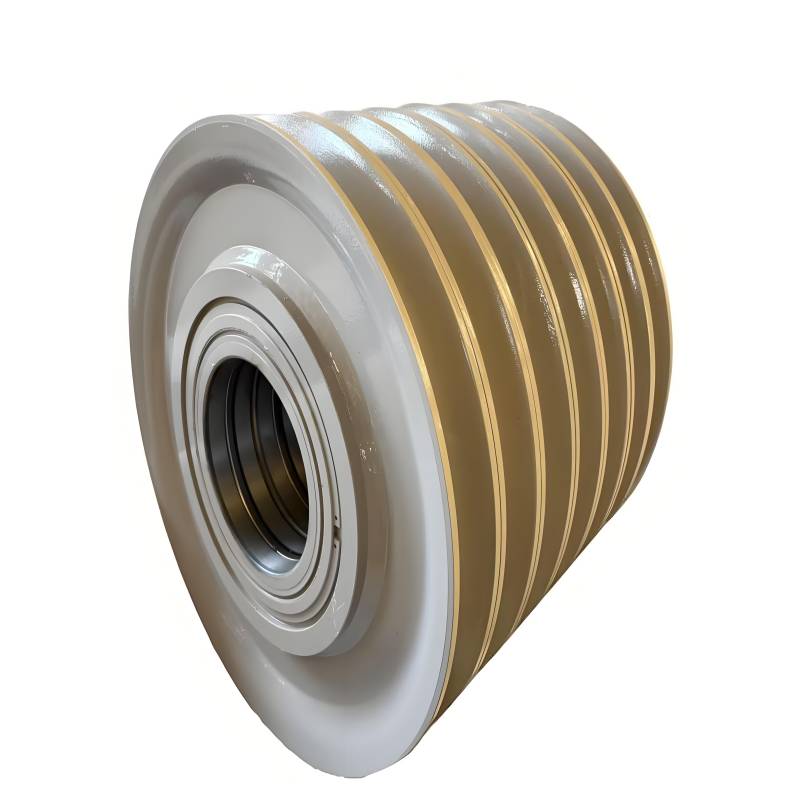

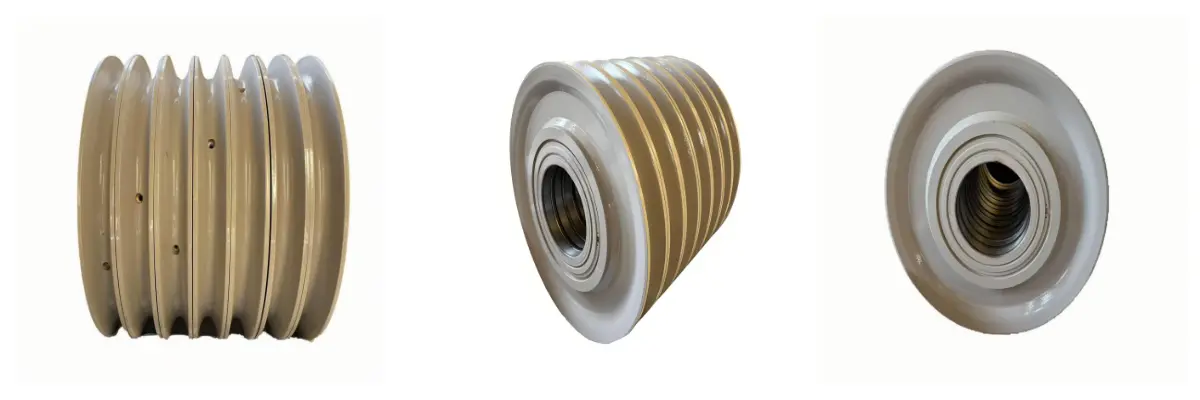

Product Advantages:

In crawler cranes, pulleys engineered with large diameters and high structural strength substantially boost load-lifting capabilities. When integrated with the crawler crane’s intrinsic stability, these pulleys effectively minimize vibration and structural deformation during hoisting operations . The pulley shafts are equipped with oversized rolling or sliding bearings, which, in conjunction with an automated lubrication system, curtail frictional energy losses and reduce the need for frequent maintenance . Featuring precision-polished surfaces and paired with low-friction bearings, this design configuration significantly lessens wire rope abrasion, enhances lifting efficiency, and demonstrates strong adaptability to intensive hoisting tasks and on-site mobility requirements . A key advantage lies in the individual replaceability of pulley components, which translates to cost-effective maintenance. Additionally, their integrated structural design streamlines routine inspections—including lubrication status checks and wear assessment—enabling rapid servicing and minimizing downtime.

Production Process:

Raw material inspection → Cutting → Rolling → Rough turning →Welding→ Deslagging→MT→ Finished turning→Drilling→ Tapping → CMM/GMM → Shot peening→Coating →Cleaning packaging

Packaging And Shipping:

Our team is committed to ensuring that every product from the prior shipment undergoes an exhaustive cleaning procedure to eliminate all dust, grime, and residual substances . Subsequently, each unit must be precisely labeled with the correct product codes and specifications. Following labeling, a premium anti-corrosion treatment will be administered to shield the items from rust during storage and transportation . Once these preliminary steps are finalized, a scrupulous quality inspection will be carried out to confirm that all products adhere to the required standards—this includes checking for manufacturing defects, verifying accurate labeling, and ensuring full coverage of the anti-corrosion treatment . Products that pass the inspection will then be carefully packaged using high-quality protective materials to safeguard against damage during handling . Finally, the packaged goods will be systematically stored in our warehouse, guaranteeing easy accessibility and readiness for prompt shipment whenever needed.

Company Strength:

Over the past three decades, our company has experienced robust growth, successfully expanding its footprint across both domestic and global markets. Our high-performance products serve as cornerstones in key sectors, including construction machinery, wind power generation, new energy vehicles, rail transit, petrochemicals, and mining equipment .

Global Market Leadership

We have established solid strategic alliances with world-renowned enterprises in major industrialized nations such as the United States, Canada, Germany, Italy, Belgium, and Japan . Today, revenue from overseas clients constitutes over 50% of our total sales, a tangible proof of our strong core competitiveness in the global marketplace . This achievement reflects our ability to align with international standards and meet the diverse needs of global partners.

Strategic Domestic Alliances

In the Chinese market, we have maintained long-term strategic collaborations with top-tier heavy machinery and equipment manufacturers, including industry leaders like Zoomlion, XCMG, Sany, Lingsheng, CRRC, Nanjing Gear, and Zhuzhou Gear. These partnerships have firmly entrenched our position as a trusted supplier in the high-end equipment sector, leveraging complementary strengths to drive industry advancement .

Market Dominance in Core Products

Fueled by relentless innovation, rigorous quality control, and a customer-centric ethos, we remain dedicated to delivering superior products and strengthening our leadership position in both domestic and global markets . Our commitment to excellence is not just a promise but a practice, rooted in decades of engineering heritage and a forward-looking mindset .