Planetary Gear For Sale

1.Material:17CrNiMo6-4/18CrNiMo7-6

2.Machining accuracy:

External cylindrical grinding: ±0.001mm

Tooth accuracy: Grade 5

3.Mold opening cycle:About 30 days

4.Customization: Made-to-order services are available.

5.Advantages:

Full-process inspection

Full-process processing capability

Full-range products

6.Weight/Size: Produce according to the drawings.

Product Introduction:

Planetary gears serve as a core component of the planetary gear mechanism within wind turbine speed-increasing gearboxes. Their manufacturing process is highly complex, typically encompassing steps like steel production, forging, post-forging normalizing and tempering, rough machining, carburizing and quenching, and finishing. Each step imposes stringent requirements on processing precision and quality. These strict standards are essential to ensure the planetary gears meet specifications for dimensional accuracy, tooth profile precision, and surface quality—ultimately safeguarding their reliable operation under high-speed, heavy-load conditions.

Product Advantages:

As a key component of the planetary gear train, planetary gears exert a direct impact on the transmission efficiency, reliability, and service life of speed-increasing gearboxes through their design and manufacturing advantages. Featuring multi-tooth load sharing, they offer high space utilization—striking an optimal balance between lightweight construction and high structural strength. Their tooth profile modification technology enhances meshing precision, enabling smooth power transmission with minimal vibration and noise. Additionally, the tooth surfaces undergo intensive shot peening: this process forms a compressive stress layer, which in turn boosts fatigue resistance and extends the gears’ service life.

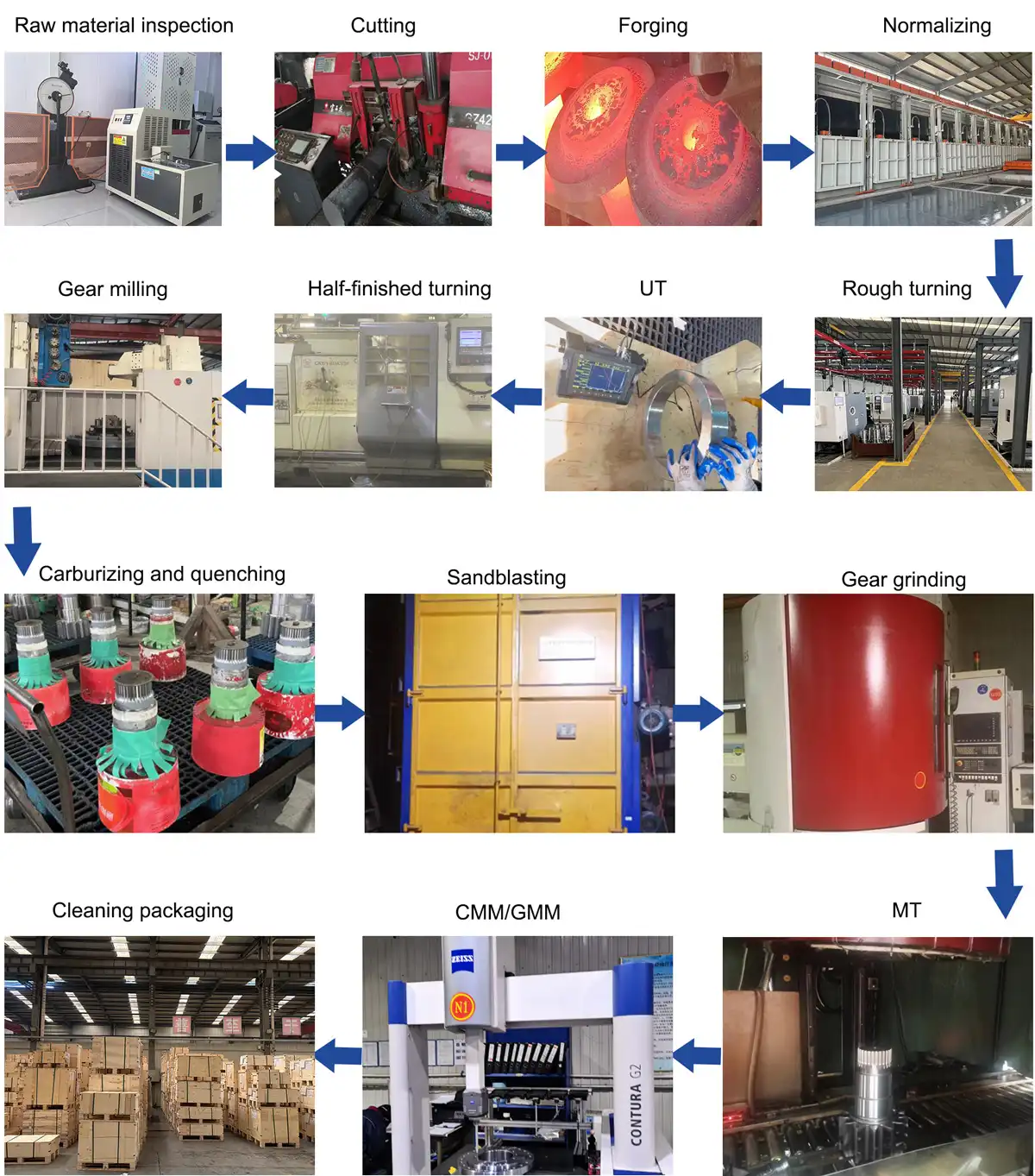

Production Process:

Raw material inspection → Cutting → Forging → Normalizing → Rough turning → UT → Half-finished turning → Gear milling → Carburizing and quenching → Sandblasting → Gear grinding → MT → CMM/GMM → Cleaning packaging

Packaging And Shipping:

Prior to shipment, all products go through a strict 5-step preparation process:

Thorough cleaning: Residual dust, debris, or manufacturing by-products are removed.

Standardized labeling: Key details (product model, batch number, specs, handling instructions) are clearly marked.

Professional rust-proofing: Anti-rust measures (e.g., anti-rust oil, corrosion-resistant films) are applied based on material.

Meticulous inspection: QC teams check for dimensional accuracy, surface finish, and defects; non-conforming items are reworked or replaced.

Secure packing & warehousing: Qualified products are packed with industry-grade materials, then stored in a climate-controlled warehouse for on-time dispatch.

Company Strength:

The company boasts a cutting-edge inspection and testing infrastructure, equipped with premium-grade equipment including imported spectrometers, nitrogen-hydrogen-oxygen analyzers, Zeiss metallographic microscopes, Zeiss coordinate measuring machines (CMMs), and M2M ultrasonic phased array flaw detectors. This advanced setup empowers the company with comprehensive testing capabilities, enabling rigorous inspections across the entire production chain—from verifying the composition and performance of raw materials, to assessing dimensional precision, structural integrity, and geometric tolerances of components, as well as conducting thorough non-destructive testing (NDT) to ensure zero hidden defects. Such end-to-end quality oversight underscores the company’s commitment to upholding industry-leading quality standards.