Wind power forgings: The "hardcore support" for stable power generation of wind turbines, all core components rely on it!

Wind power forgings: The "hardcore support" for stable power generation of wind turbines, all core components rely on it!

Against the backdrop of the rapid development of the wind power industry towards large capacity, high altitude and deep sea, wind turbine equipment needs to withstand multiple tests such as strong wind loads, alternating stress and extreme temperature differences. Forgings, as the "strength core" of wind power equipment, have become the preferred manufacturing process for key components such as the main shaft, hub, and tower flange of wind turbines due to their excellent mechanical properties and fatigue resistance. Many wind turbine manufacturers and component purchasers are puzzled: In which core parts are wind turbine forgings specifically used? Why can high-quality forgings determine the service life of fans? How to select forging products that are suitable for different wind field conditions? This article will comprehensively disassemble the core value of wind power forgings from three major dimensions: application scenarios, process advantages, and key points for selection.

I. Wind Power forgings: The core components of the "heart" and "skeleton" of wind turbines

The stable operation of a megawatt-level wind turbine cannot do without the coordinated support of dozens of high-precision forgings. From the main shaft that transmits power, to the hub that supports the blades, and then to the flange that connects the tower, the forgings run through the core load-bearing components of the wind turbine and are the key to ensuring the power generation efficiency:

Main shaft forging: The "power transmission center" of the fan

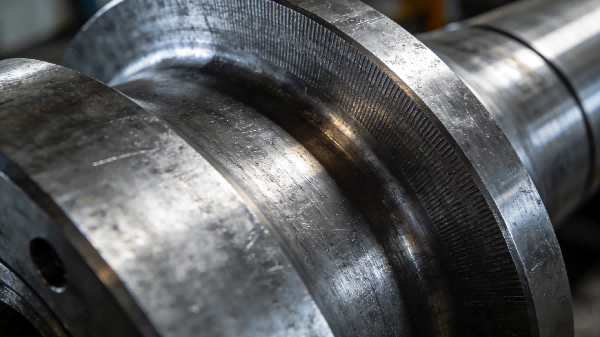

The main shaft of the fan is the core component connecting the impeller and the gearbox, and it needs to withstand the huge torque, alternating load and impact stress brought by the rotation of the blades for a long time. The main shaft forgings are usually made of high-strength alloy structural steels such as 42CrMo, and are produced through multiple processes including die forging and quenching and tempering heat treatment. High-quality main shaft forgings have uniform and dense internal grains, free of pores, porosity and other defects. Their tensile strength can reach over 800MPa, ensuring stable power transmission without deformation or fracture during a service life of more than 20 years. They are the "power lifeline" for efficient power generation of wind turbines.

Hub forgings: The "supporting core" of blades

As a key component connecting the three blades, the wind turbine hub needs to concentrate and transfer the rotational force of the blades to the main shaft, while also bearing the uneven load brought by the strong wind. Hub forgings are mostly of integral forging structure. Compared with castings, their impact resistance and fatigue resistance are improved by more than 50%, which can effectively avoid the risk of cracking caused by local stress concentration. In offshore wind farms, corrosion-resistant alloy forged hubs can also resist the corrosion of high salt spray and high humidity, thus extending the maintenance cycle of the entire machine.

Tower flange forgings: The "connecting link" of the tower

The wind turbine tower is composed of multiple sections of steel pipes, and the tower flange is the core component that enables the tight connection of each section of the tower. It needs to bear the self-weight of the entire wind turbine and the wind load. The flange forgings are made by ring forging process to ensure the flatness of the flange plane and the positional accuracy of the bolt holes. Its high strength can prevent the tower from loosening or deforming under strong wind, providing a stable "skeleton support" for the fan. In addition, key components such as the main shaft bearing housing and the planetary carrier of the gearbox are all customized forged products.

Yaw and pitch forgings: The "Key to Intelligent Regulation" of wind turbines

The yaw system (adjusting the nacelle direction to align with the wind direction) and pitch system (adjusting the blade Angle to control power) of the wind turbine, their core components such as the yaw bearing housing and pitch gears, also rely on forgings for manufacturing. These forgings need to have the characteristics of high precision and high wear resistance to ensure the precise response of yaw and pitch actions, allowing the wind turbine to maintain the best power generation state at different wind speeds.

Ii. Forging Process: The "Core Code" for Wind Power Forgings to Adapt to Extreme Working Conditions

The service environment of wind power equipment is extremely harsh - onshore wind turbines have to deal with temperature differences ranging from -30 ℃ to + 40℃ and sand and dust erosion. Offshore wind turbines have to withstand salt spray corrosion and the impact of huge waves. Ordinary castings or welded parts simply cannot meet the demands of long-term stable operation, while forgings stand out with their unique technological advantages:

Ultimate strength, resistant to extreme loads

Forging process involves subjecting metal billets to high-temperature and high-pressure forging, which can break down the coarse grains inside the metal, refine the grains and distribute them along the direction of force, completely eliminating common defects such as gas holes, sand holes and shrinkage cavities in castings. Forged wind power components have tensile strength, yield strength and fatigue resistance far exceeding those of castings, which can easily cope with alternating loads and strong wind impacts during the operation of wind turbines, significantly reducing the risk of component failure.

It has strong fatigue resistance and can extend the service life of the fan

The designed service life of a fan is typically 20 to 25 years, and its core components need to withstand tens of thousands of stress cycles. The continuous metal fiber structure of the forging is consistent with the force direction of the component, and its fatigue resistance limit is much higher than that of other processed products. For instance, after the main shaft forgings undergo quenching and tempering treatment, their fatigue resistance can be enhanced to 2 to 3 times that of castings, ensuring no fatigue fracture occurs during long-term operation and providing a guarantee for stable power generation throughout the entire life cycle of the wind turbine.

Precise dimensions enhance assembly efficiency

Precision forging technology can achieve "near-net forming" of wind power forgings, with dimensional tolerances controlled at the micrometer level. Only a small amount of fine processing is required subsequently to meet the assembly requirements. Take the tower flange forging as an example. Its flatness error can be controlled within 0.5mm, and the positional accuracy deviation of the bolt holes does not exceed 0.1mm. It can be precisely connected with the tower steel pipe directly, avoiding vibration and abnormal noise caused by excessive assembly clearance, and improving the operational stability of the entire machine.

The material is controllable and suitable for various working conditions

For the working conditions of different wind farms, the forging process can flexibly combine materials: For onshore low-wind-speed wind farms, ordinary alloy forgings can be selected to control costs. For high-altitude and low-temperature wind fields, low-temperature resistant alloy forgings can be selected to prevent component brittle fracture. For offshore wind farms, corrosion-resistant stainless steel forgings can be selected, combined with anti-corrosion coatings, to resist salt spray erosion. This customized material selection enables wind power forgings to adapt to various complex application scenarios.

Iii. Wind Power Forgings Selection Guide: 3 Core Points to Avoid Procurement Misunderstandings

For wind turbine manufacturers and operation and maintenance enterprises, choosing the right forgings is the key to reducing equipment failure rates and improving power generation efficiency. When purchasing, the following three points should be given special attention:

Verify the process and test report

Give priority to choosing wind power forgings made by die forging process. The performance of die forgings is far superior to that of free forgings. At the same time, suppliers are required to provide complete inspection reports, including material test reports, non-destructive testing reports (ultrasonic flaw detection, magnetic particle flaw detection), mechanical property test reports, etc., to ensure that the forgings have no internal defects and that all performance indicators comply with national or industry standards.

Select the material to match the wind farm conditions

Select the corresponding material of forgings based on the type of wind farm (onshore/offshore, high-altitude/low-altitude) : For offshore wind farms, focus on corrosion resistance, and give priority to stainless steel or weathering steel forgings. For high-altitude low-temperature wind farms, alloy forgings with low-temperature impact toughness meeting the standards should be selected. For large-capacity fans, high-strength forgings should be selected to meet the requirements of large torque transmission.

Pay attention to the heat treatment process

Heat treatment is a key step in enhancing the performance of wind power forgings. High-quality forging suppliers will, based on the application of the components, adopt different heat treatment processes such as quenching and tempering, carburizing, and nitriding to ensure that the hardness, toughness, and wear resistance of the forgings reach the best balance. When making a purchase, you can request to review the heat treatment process records to avoid premature failure of components due to inadequate heat treatment.

Iv. Industry Trends: Large-megawatt wind turbines drive the upgrading of wind power forgings

As the wind power industry moves towards larger megawatts and lighter weight, the size and load capacity of wind turbine components are also constantly increasing. For instance, the main shaft of a 16MW offshore wind turbine is over 10 meters long and weighs more than 100 tons, which poses higher demands on the manufacturing capacity of forgings. In the future, wind power forgings will develop towards the direction of super-large size, high precision and integrated forging. Meanwhile, the application of digital forging technologies (such as digital twins and intelligent detection) will further enhance the quality stability of forgings and help the wind power industry reduce costs and increase efficiency.

Summary

Forgings are the "hardcore foundation" of wind power equipment. From the main shaft, hub to the tower flange, the quality of each key forging directly determines the operational stability and service life of the wind turbine. In the current era of rapid development in the wind power industry, choosing high-quality and suitable wind power forgings is the core key for wind turbine manufacturers to enhance product competitiveness and for operation and maintenance enterprises to reduce maintenance costs.

If you need to know more about customized solutions for wind power forgings, technical parameters of forgings for different megawatt wind turbines, or obtain industry standard comparison tables for wind power forgings, please feel free to contact us at any time!