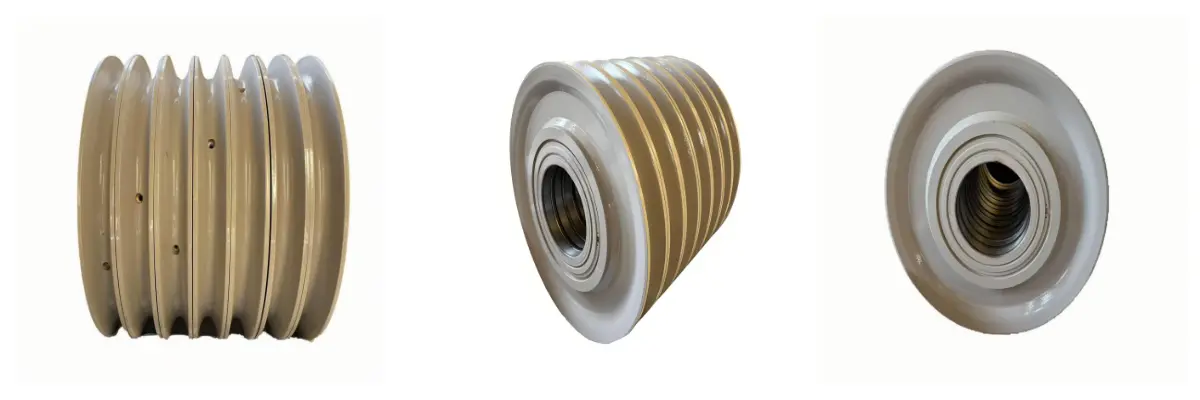

Crane Block Sheaves System

1.Material:Q355B\Q355D\Q550D\35#

2.Machining accuracy:±0.1mm

3.Mold opening cycle:About 30 days

4.Customization: We design and manufacture tailor-made products to your exact technical requirements.

5.Advantages:

Our strict process inspection ensures every product meets defect-free standards.

Streamlined one-stop processing delivers efficiency and cost savings.

From standard to custom, our wide product range solves all your needs.

6.Weight/Size:Execute custom orders with complete compliance to the drawings provided.

Product Introduction:

The crane pulley, as an necessary transmission accent in the hook assembly, modifications the route of pressure and saves hoisting power consumption via the precept of rolling friction. It is a key element for enhancing hoisting effectivity and stability, and performs an irreplaceable position in a number of lifting equipment.

Product Advantages:

In crawler cranes, large-diameter and high-strength pulleys can substantially decorate lifting capacity. Combined with the universal steadiness of crawler cranes, they decrease shaking and deformation in the course of lifting. The pulley shafts undertake large-diameter rolling bearings or sliding bearings, blended with an automated lubrication system, to minimize frictional loss and renovation frequency. The pulley floor is polished and matched with low-resistance bearings to reduce wire rope wear, enhance lifting efficiency, and go well with regularly occurring lifting and site-transfer operations. Pulley aspects can be changed individually, providing low protection costs; their easy shape helps every day inspections (such as lubrication and put on detection), making rapid protection feasible.

Production Process:

Raw material inspection → Cutting → Rolling → Rough turning →Welding→ Deslagging→MT→ Finished turning→Drilling→ Tapping → CMM/GMM → Shot peening→Coating →Cleaning packaging

Packaging And Shipping:

Our team will ensure all merchandise from the previous shipment undergoes a thorough cleaning process to remove any dust, dirt, or residues. Each item should then be properly labeled with the correct product codes and specifications. After labeling, apply a high-quality rust-proofing treatment to protect the goods from corrosion during storage and transit. Once these steps are complete, conduct a meticulous inspection to verify that all items meet quality standards—checking for defects, proper labeling, and complete rust-proofing coverage. After passing inspection, carefully pack the merchandise using appropriate protective materials to prevent damage. Finally, store the packed goods in our warehouse in an organized manner, ensuring they are easily accessible and fully prepared for prompt dispatch when needed.

Company Strength:

Over the past three decades, our company has achieved dynamic growth, successfully expanding across both domestic and global markets. Our high-performance products play a vital role in key industries, including construction machinery, wind power generation, new energy vehicles, rail transit, petrochemicals, and mining equipment.

Global Market Leadership

We have forged strong partnerships with internationally renowned corporations in the United States, Canada, Germany, Italy, Belgium, Japan, and other leading industrial nations. Today, overseas customer revenue contributes to over 50% of our total sales, reflecting our strong competitiveness in the global market.

Strategic Domestic Alliances

In China, we maintain long-term strategic collaborations with top-tier heavy machinery and equipment manufacturers, including industry leaders such as Zoomlion, XCMG, Sany, Lingsheng, CRRC, Nanjing Gear, and Zhuzhou Gear. These partnerships reinforce our position as a trusted supplier in the high-end equipment sector.

Market Dominance in Core Products

Planetary reducer core forgings – Essential for precision machinery and automation systems.

Medium-to-large lifting hook assemblies– Widely used in heavy-load applications such as cranes and industrial hoists.

With continuous innovation, strict quality control, and a customer-centric approach, we remain committed to delivering superior products and strengthening our leadership in both domestic and international markets.