Hinges for Truck Cranes

1.Material:18CrNiMo7-6/20CrMnTi/35CrMo

2.Machining accuracy: ±0.1mm

3.Mold opening cycle: About 45 days

4.Customization: Fabricate tailor-made products that precisely align with your technical specifications

5.Advantages:

Full-process inspection

Full-process processing capability

Full-range products

6. Weight:We will ascertain the material usage and the weight of the finished products according to the drawings provided by the customers.

7.Craft:Forging

Product Introduction:

Hinges for crawler cranes and truck cranes are critical connecting components in lifting equipment. Acting as the "joints" between a crane’s boom sections and its main structure, they play an essential role in transmitting massive loads, while ensuring the boom’s flexible rotation and stable operation. Whether for the heavy-duty lifting tasks of crawler cranes or the agile, rapid operations of truck cranes, the reliable performance of these hinges directly impacts the crane’s safety, dependability, and work efficiency.

Product Advantages:

The hinge (also referred to as a trunnion or hinge base) in cranes—including crawler cranes and truck cranes—is a critical connecting component for key parts such as the boom, outriggers, and slewing mechanism. Its core function is to transfer loads, enable relative rotation between components, and ensure the stability and flexibility of the entire equipment structure. It features high-strength load transfer and fatigue resistance, high-precision hinging and flexible movement, integrated hinge design, wear-resistant surface treatment, quick assembly and disassembly, and optimized maintenance costs.

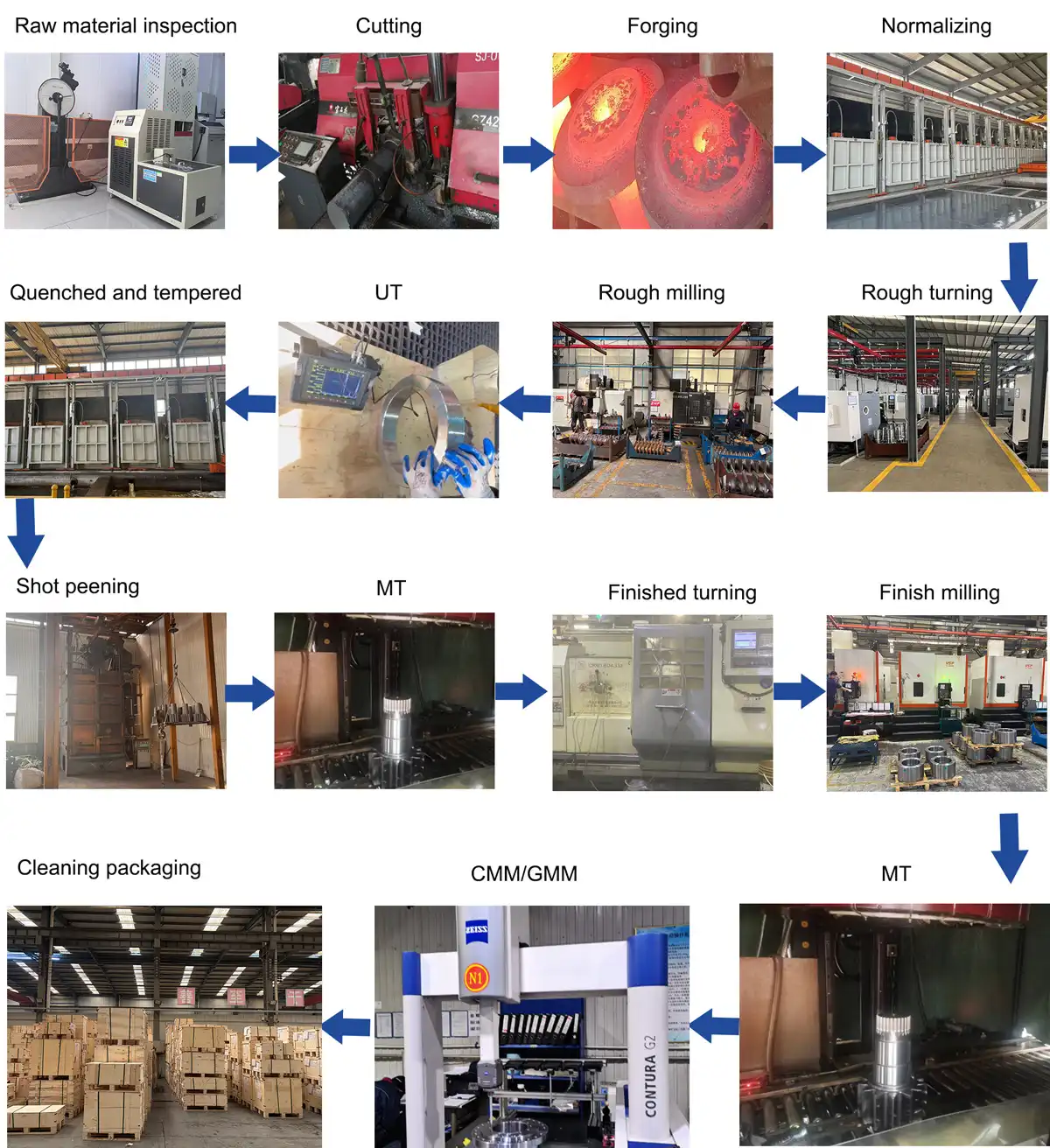

Production Process:

Raw material inspection → Cutting → Forging → Normalizing → Rough turning → Rough milling → UT → Quenched and tempered → Shot peening → MT → Finished turning → Finish milling → MT → CMM/GMM → Cleaning packaging

Packaging And Shipping:

Our dedicated team of specialists adheres to a stringent, multi-step quality control protocol for every customer order. Prior to shipment, each product undergoes three critical preparatory steps: deep cleaning to remove any residual debris or manufacturing byproducts, clear, standardized labeling that includes part numbers, batch codes, and handling instructions, and industry-grade rust-inhibiting treatment (such as anti-corrosive coating or VCI packaging) to protect against oxidation during transit. Following these preparations, a comprehensive visual inspection is conducted by our quality assurance team—checking for surface defects, proper treatment application, and label accuracy—to ensure full compliance with our premium quality standards and customer requirements. Finally, we carefully package each product using shock-absorbent materials (e.g., foam inserts, reinforced cartons) tailored to its size and weight, then store the packaged items in our temperature-controlled, well-organized warehouse. This storage setup maintains product integrity and allows for quick retrieval, ensuring orders are fully prepared for prompt, on-time delivery to our customers worldwide.

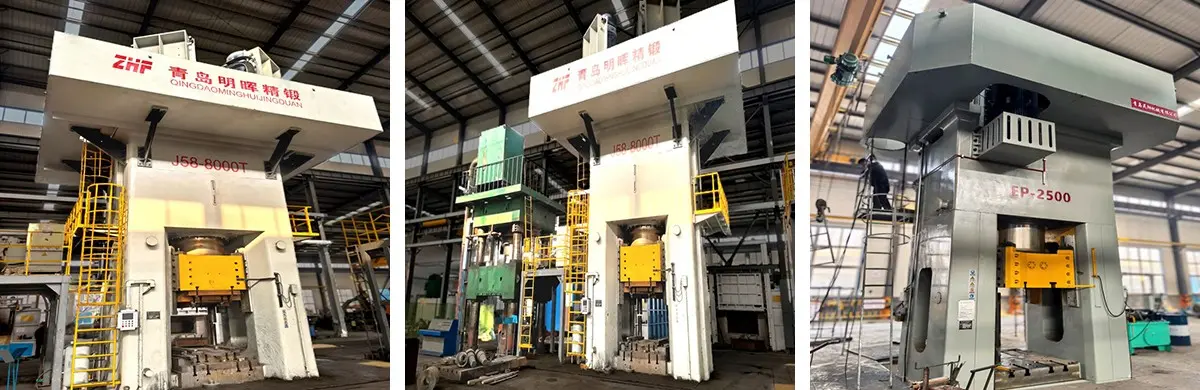

Company Strength:

The organization has successfully obtained and maintained certifications for the ISO 9001 Quality Management System, ISO 14001 Environmental Management System, and ISO 45001 Occupational Health and Safety Management System—all awarded by TÜV Rheinland, a globally renowned certification body with a century-long reputation for rigorous quality and compliance assessments. These certifications are not just formal recognitions; they reflect the organization’s systematic commitment to upholding international standards across every operational layer: from streamlining production processes and ensuring consistent product quality (ISO 9001) to minimizing environmental impact through waste reduction and sustainable resource use (ISO 14001), and prioritizing employee well-being via robust workplace safety protocols (ISO 45001).

Beyond these foundational certifications, the organization’s exceptional management capabilities—including its agile response to market demands, customer-centric service framework, and data-driven operational optimization—have earned wide recognition from both leading international industry players (such as global engineering firms and Fortune 500 partners) and key domestic market authorities. This recognition is further validated by a series of prestigious honors it has secured, including the "Outstanding Supplier" award (bestowed for its consistent on-time delivery, flexible order fulfillment, and proactive post-sales support) and the "Best Quality Award" (recognized for its zero-defect product track record and strict quality control measures throughout the R&D, manufacturing, and delivery cycles). Together, these achievements solidify the organization’s standing as a reliable, responsible, and high-performing partner in its industry.