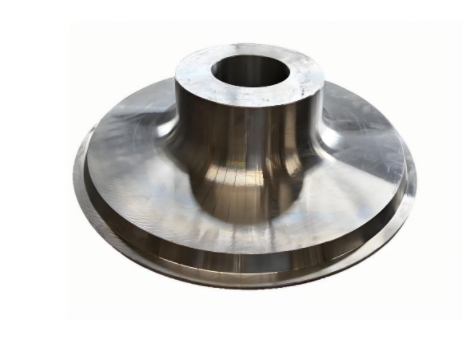

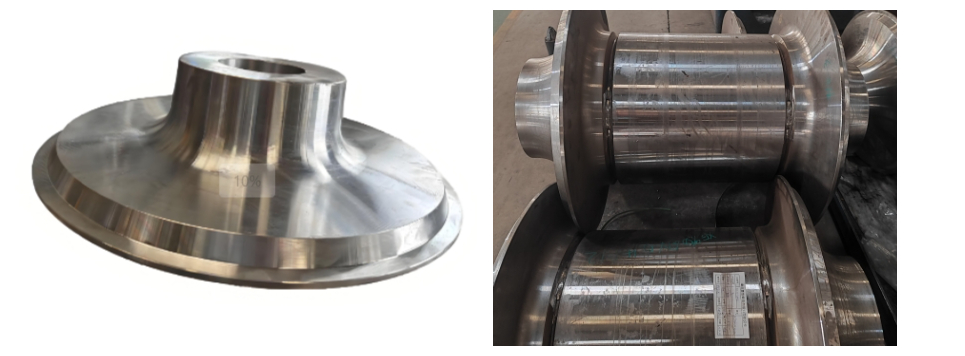

High Quality Intermediate Support Shaft

1.Material:35#(ASTM:1035 EN:C35E4 DIN:CK35),20MnMo

2.Mold opening cycle:About 45 days

3.Customization: We design and manufacture tailor-made products to your exact technical requirements.

4.Advantages:

Our strict process inspection ensures every product meets defect-free standards.

Streamlined one-stop processing delivers efficiency and cost savings.

From standard to custom, our wide product range solves all your needs.

5.Weight:Material usage and end-product weight will be derived from the Client’s provided drawings.

6.Craft:Forging

7.Size:Execute custom orders with complete compliance to the drawings provided.

Product Introduction:

The center help seat (also recognised as the center shaft seat, center help seat or rear support) of the growth of the excavator growth is the core load-bearing issue connecting the growth and the boom, enjoying a integral function in transmitting loads, making sure balance and reaching bendy movement. In the future, with the popularization of self-sensing lubrication structures and predictive protection technologies, the center help seat will in addition improve toward an built-in course of "self-adaptation - self-repair - lengthy provider life", turning into the core competitiveness of high-end excavators.

Product Advantages:

The blessings of its merchandise are ordinarily mirrored in structural innovation, cloth technology, ease of preservation and adaptability to more than a few scenarios. The characteristic of the mechanical hub: The center aid seat is positioned at the center give up of the bucket arm and is hinged to the growth thru a pin shaft. It transmits the influence hundreds at some stage in operation (such as bucket resistance and vibration torque) to the growth and chassis structure, and at the equal time serves as the axis for the rotation of the bucket arm, controlling the depth and Angle accuracy of the excavation. The core blessings of the guide seat in the increase of the excavator's boom, such as built-in design, anti-eccentric load bolstered structure, central symmetrical support, bolstered plate layout, adjustable design, and positioning anti-seepage, lie in its exceedingly dependable structure: the anti-eccentric load format and the standard forging manner resolve the cracking problem. Intelligent functions: Adjustable length/Angle to adapt to a couple of scenarios, and embedded sensors for predictive maintenance. Full existence cycle fee optimization: Modular inclined components + self-lubrication gadget reduces upkeep fees through 40%.

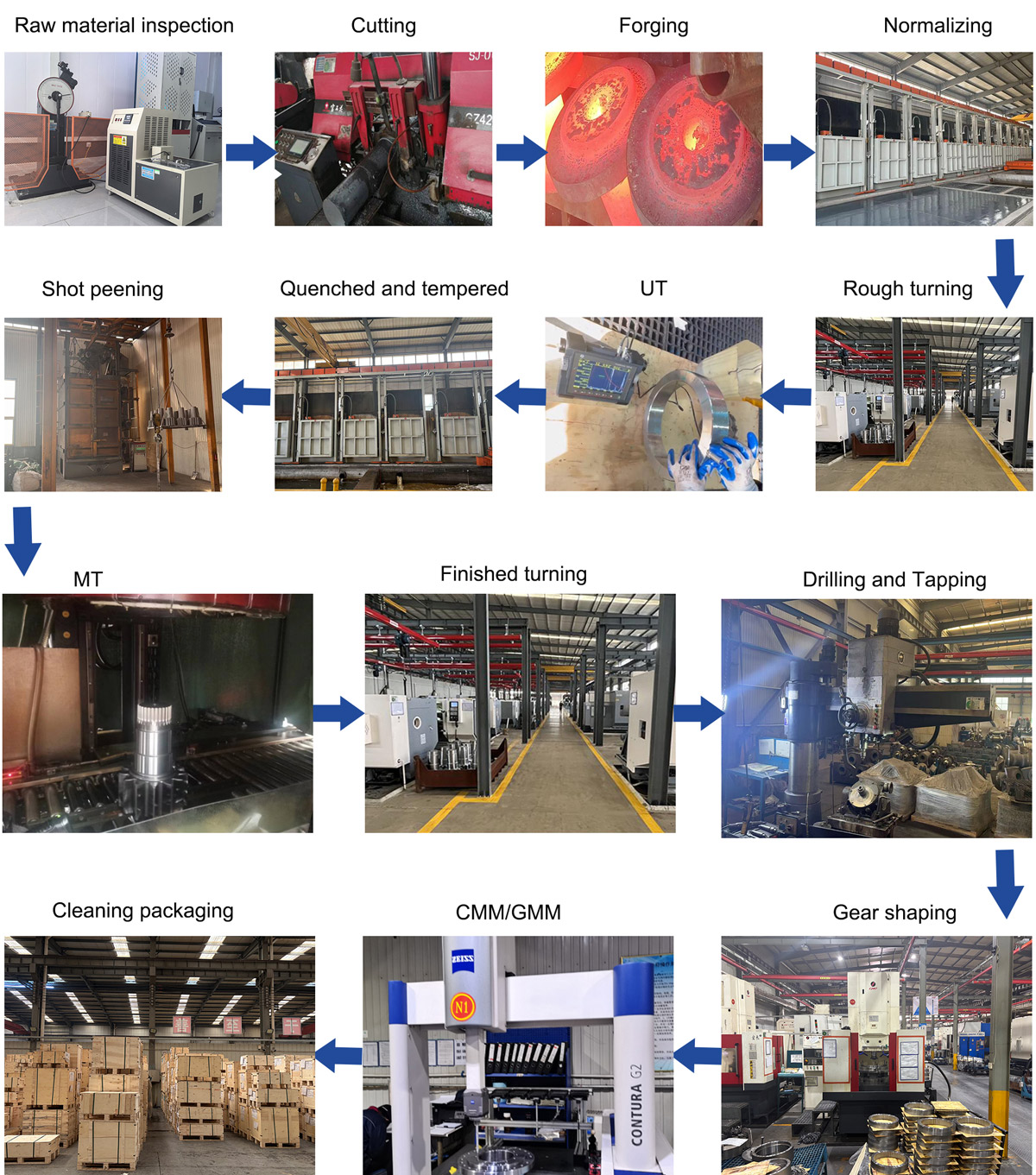

Production Process:

Raw Material Inspection → Cutting → Forging → Heat Treatment/Tempering → Shot Blasting → Rough Machining → Ultrasonic Testing (UT) → Final Inspection → Cleaning Packaging

Our team will:

Clean, label, and take a appear at rust-proofing to all merchandise beforehand than shipment;

Perform a meticulous showcase up inspection

Finally pack the merchandise and hold them in our warehouse, making gorgeous readiness for dispatch.

Company Strength:

Over the previous 30 years of active development, the company has aggressively prolonged into each and every and every home and world markets. Its merchandise are drastically used in fields such as putting up machinery, wind electrical electricity generation, new electrical energy vehicles, rail transit, petrochemicals, and mining machinery. The business enterprise has established in-depth cooperation with world-renowned corporations in the United States, Canada, Germany, Italy, Belgium, Japan, and superb countries, with some distance away areas capital client profits accounting for large than 50%. It has in addition established strategic partnerships with home predominant high-end tools producers such as Zoomlion, XCMG, Sany, Lingsheng, CRRC, Nanjing Gear, and Zhuzhou Gear. Among its products, the market share of planetary reducer core forgings and medium-to-large lifting hook assemblies ranks first in the home market.