Heavy Duty Crane Hook Assembly

1.Material:45\35CrMo\40Cr\42CrMo\30Cr2Ni2Mo

2.Machining accuracy:±0.1mm

3.Mold opening cycle:About 45 days

4.Customization: Made-to-order services are available.

5.Advantages:

Full-process inspection

Full-process processing capability

Full-range products

6.Weight/Size: Produce according to the drawings.

7.Craft:Forging

Product Introduction:

The hook assembly is a key element in lifting equipment used for grabbing and hoisting loads. Processed via forging technology, it aspects a dense interior structure, greater electricity and toughness, and specifically extremely good influence resistance, enabling it to stand up to heavy masses and conventional use. It is in most cases utilized in the industrial sector, building field, logistics and warehousing field, and transportation field.

Product Advantages:

The hook assembly of crawler cranes aspects excessive load-bearing capability and have an effect on resistance, adapts to harsh working conditions, and is appropriate for heavy-duty hoisting and complicated terrains. It makes use of high-strength materials, heavy-duty designs, and more than one security safety devices, making it appropriate for long-term heavy-duty operations with a bendy working range. The hook meeting of truck cranes is characterised with the aid of mild weight, excessive mobility, flexibility, efficiency, and handy maintenance. It is appropriate for medium and small hoisting, city operations, widespread relocations, and multi-scenario applications. It adopts light-weight materials, compact designs, and standardized components.

Production Process:

Raw material inspection → Cutting → Forging → Normalizing →Grinding→Rough turning →Quenched and tempered→ MT+UT→ Finished turning→ Milling groove →Drilling → CMM/GMM → Shot peening→Coating →Cleaning packaging

Packaging And Shipping:

Our expert team enforces strict exceptional manipulate for every and each and every order. Before shipment, all merchandise are fully cleaned, without a doubt labeled, and dealt with with rust-proof coating. A complete seen inspection follows to assurance pinnacle category quality. Finally, we cautiously bundle and shop objects in our geared up warehouse for instantaneous dispatch readiness.

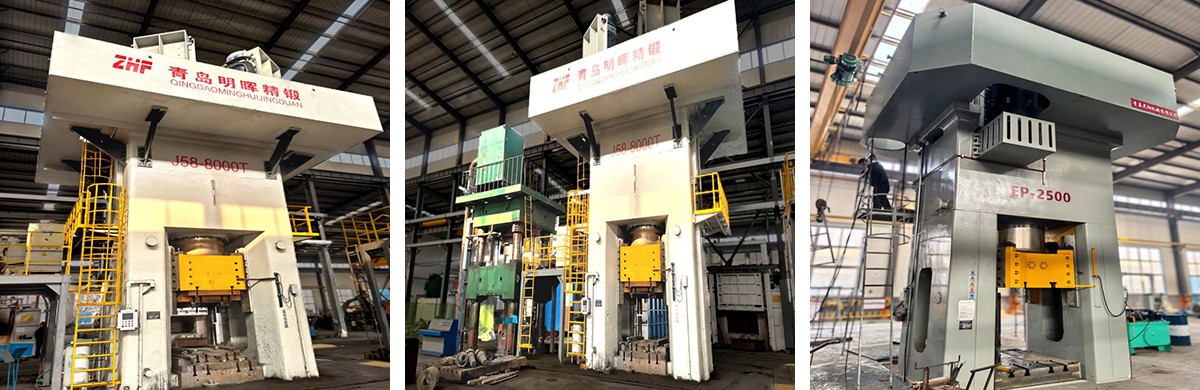

Company Strength:

The organisation is geared up with most really useful inspection and making an attempt out devices such as imported spectrometers, nitrogen-hydrogen-oxygen analyzers, Zeiss metallographic microscopes, Zeiss CMMs, and M2M ultrasonic phased array flaw detectors. It has the whole traditional average overall performance to habits inspections from raw cloth composition, performance, dimensions, shape and attribute tolerances to non-destructive testing.