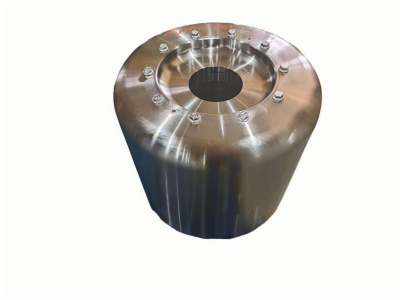

Hook Assembly Nut

1.Material:45\35CrMo\42CrMo\30Cr2Ni2Mo

2.Machining accuracy:±0.1mm

3.Mold opening cycle:About 30days

4.Customization: We design and manufacture tailor-made products to your exact technical requirements.

5.Advantages:

Our strict process inspection ensures every product meets defect-free standards.

Streamlined one-stop processing delivers efficiency and cost savings.

From standard to custom, our wide product range solves all your needs.

6.Weight/Size:Material usage and end-product weight will be derived from the Client’s provided drawings.

Product Introduction:

The nut, as an unremarkable yet crucial connecting accessory in the hook group, is small in size but undertakes the core functions of fixing key components and transmitting loads, serving as an "invisible guardian" that ensures the overall stability of the lifting system. In the assembly system of the hook group, the main role of the nut is to cooperate with bolts and screw rods to fasten and connect components such as the pulley shaft, crossbeam, and hook body, preventing loosening in the vibrating and impactful environment of lifting operations.

Product Advantages:

In the hook assembly, nuts are typically used to secure core components such as the hook shaft, pulley shaft, and crossbeam. Through the preload generated by threaded connections, they tightly lock various components together, preventing connection loosening caused by vibration, impact, or swinging of heavy objects during lifting operations. The threaded design of the nuts allows for a certain range of tightness adjustment, facilitating the adjustment of relative positions of components during assembly or maintenance, ensuring that all parts of the hook block are in optimal cooperation. For components that need to be frequently disassembled or replaced, the removability of nuts simplifies the maintenance process and improves the efficiency of equipment inspection and repair.

Production Process:

Raw material inspection → Cutting → Forging→ Normalizing → Rough turning →Quenched and tempered→MT+UT→ Finished turning→Milling groove→Drilling→Tapping → CMM/GMM → Shot peening→Coating →Cleaning packaging

Packaging And Shipping:

Our committed crew adheres to a strict first-rate manipulate protocol for every and each and every order. Each product is meticulously cleaned, truely labeled, and safeguarded with rust prevention measures in the preceding than shipment. Subsequently, a rigorous exhibit up inspection is carried out to make fine flawless quality. Finally, we professionally bundle deal and hold the merchandise in our well-organized warehouse, guaranteeing on the spot readiness for delivery.

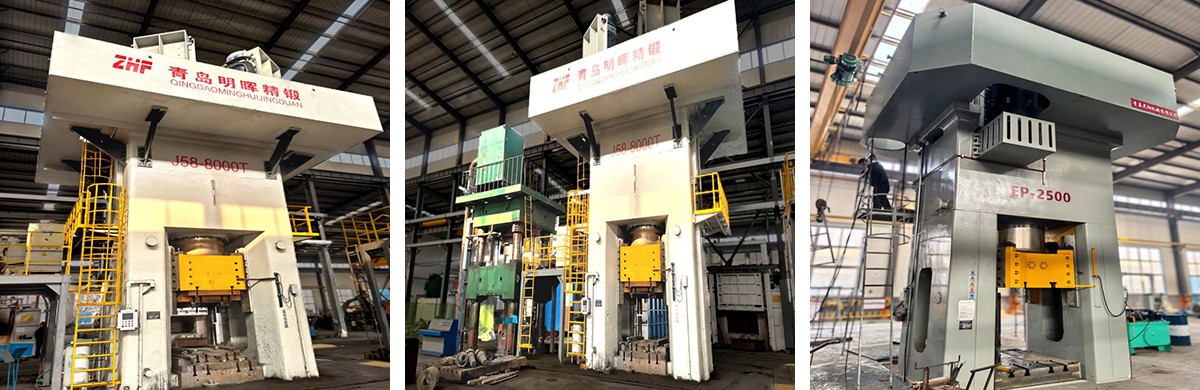

Company Strength:

The organization has got certifications for ISO 9001 Quality Management System, ISO 14001 Environmental Management System, and ISO 45001 Occupational Health and Safety Management System from TÜV Rheinland. Its excellent administration abilities have been identified through global and home enterprise leaders, and it has obtained severa honors such as Outstanding Supplier and Best Quality Award.