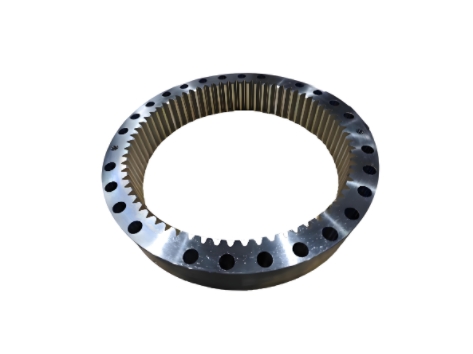

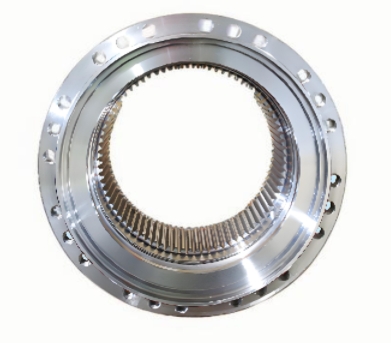

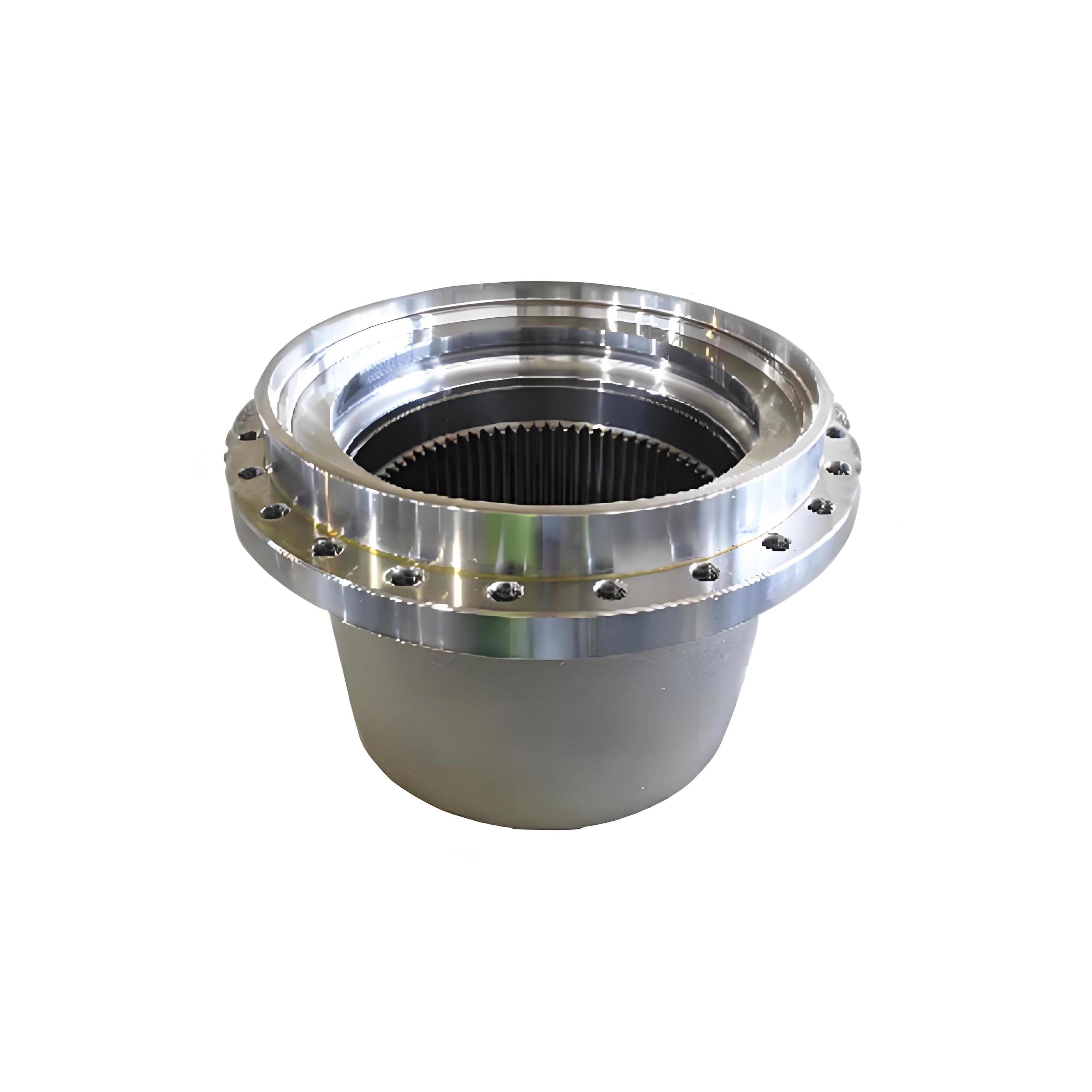

Precision Engineered Ring Gear

1.Material:42CrMo/40Cr

2.Machining accuracy:±0.01mm

3.Mold opening cycle:About 45 days

4.Customization: We design and manufacture tailor-made products to your exact technical requirements.

5.Advantages:

Our strict process inspection ensures every product meets defect-free standards.

Streamlined one-stop processing delivers efficiency and cost savings.

From standard to custom, our wide product range solves all your needs.

6.Weight:Material usage and end-product weight will be derived from the Client’s provided drawings.

7.Craft:Forging

Product Introduction:

The indoors gear ring is a core component in mechanical transmission systems, belonging to the kind of equipment parts. Its structural attribute lies in the interior teeth design, which transmits electrical power and action with the useful resource of meshing with exterior gears. As a "precision link" in electrical strength transmission, the graph selection of the interior tools ring at as quickly as influences gear effectivity and lifespan. Whether it is the powder metallurgy tools ring in auto transmissions, the carburized steel equipment ring in wind turbine gearboxes, or the nylon coupling inside tools ring in robotic joints, its rate is manifested in high-precision meshing, dependable pressure transmission, and environmental adaptability.

Product Advantages:

The interior ring equipment is a core trouble in mechanical transmission systems, renowned for its high-efficiency transmission, compact structure, immoderate load capacity, and have an influence on resistance. Featuring an annular interior enamel design, it meshes with exterior gears (such as planetary gears and photo voltaic gears) to attain over 95% transmission effectivity while minimizing power loss. Its compact structure makes it in specific fabulous for space-constrained scenarios, enabling first-rate integration into elaborate transmission systems.The topped enamel diagram enhances load functionality with the aid of 15%~20% in distinction to straight teeth, optimizing contact surfaces to minimize stress focus and extend service life. Carburized and quenched metallic interior ring gears exhibit off a hardness of 57~62 HRC, allowing them to stand up to high-load and high-impact stipulations in metallurgical and wind electricity equipment.These gears are substantially utilized in the course of industries including:Automotive Industry.Wind Power and Engineering Machinery.Aerospace.Medical Devices

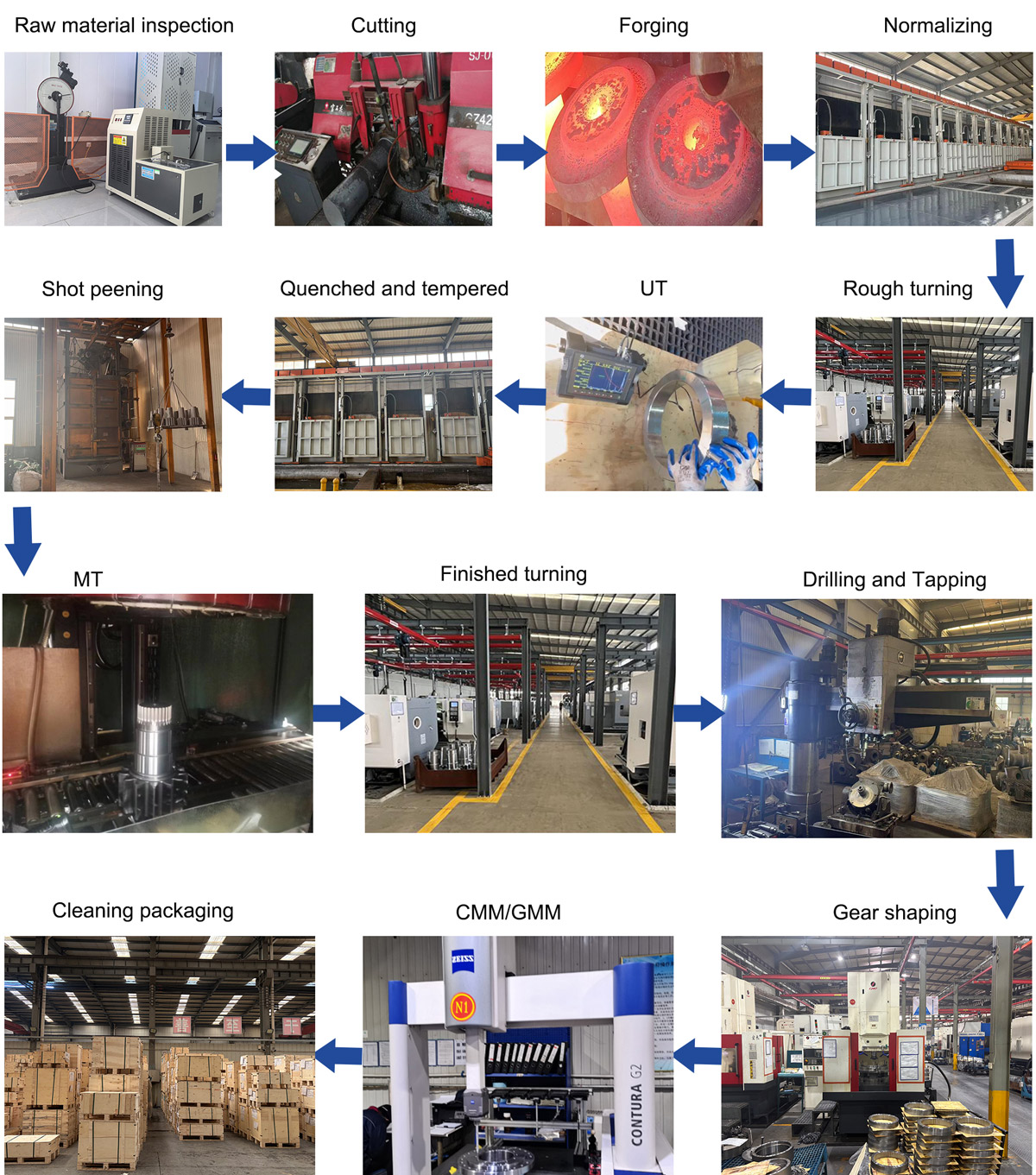

Production Process:

Raw material inspection→ Cutting→ Forging → Normalizing → Rough turning → UT → Quenched and tempered → Shot peening → MT → Finished turning → Drilling and Tapping → Shaping → CMM/GMM → Cleaning packaging

Our team will:

Clean, label, and take a show up at rust-proofing to all merchandise until now than shipment;

Perform a meticulous exhibit off up inspection;

Finally pack the merchandise and preserve them in our warehouse, making awesome readiness for dispatch.

Company Strength:

Over the preceding 30 years of lively development, the corporation has aggressively extended into every and each and every domestic and world markets. Its merchandise are substantially used in fields such as inserting up machinery, wind electrical electricity generation, new electrical power vehicles, rail transit, petrochemicals, and mining machinery. The business enterprise has hooked up in-depth cooperation with world-renowned organizations in the United States, Canada, Germany, Italy, Belgium, Japan, and super countries, with a lengthy way away areas capital customer profits accounting for multiplied than 50%. It has in addition sizeable strategic partnerships with domestic predominant high-end gear producers such as Zoomlion, XCMG, Sany, Lingsheng, CRRC, Nanjing Gear, and Zhuzhou Gear. Among its products, the market share of planetary reducer core forgings and medium-to-large lifting hook assemblies ranks first in the domestic market.