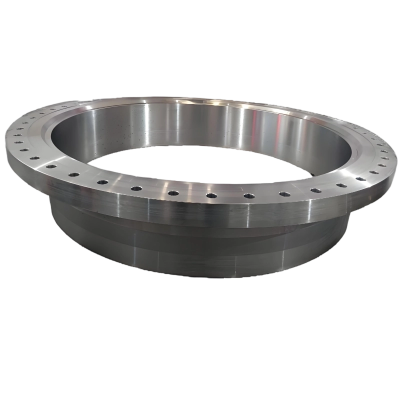

Custom Output Gear Shafts

1.Material:17CrNiMo6-4/18CrNiMo7-6/20CrMnMo

2.Machining accuracy:

External cylindrical grinding: ±0.001mm

Tooth accuracy: Grade 5

3.Mold opening cycle:About 45 days

4.Customization: Customization is accepted.

5.Advantages:

Full-process inspection

Full-process processing capability

Full-range products

6.Weight: Depend on client selection

7.Craft:Forging

Product Introduction:

A key transmission phase linking the electricity output quit in a slewing velocity reducer, the output gear shaft specifically serves to switch the torque from internal the reducer to exterior masses (like slewing rings, gearboxes, and so on). The transmission efficiency, stability, and provider existence of the gear are all at once impacted through its sketch and performance.

Product Advantages:

In wind strength and development equipment slewing reducers, the output gear shaft acts as a essential phase linking the transmission device and the actuator. Its diagram and overall performance have a direct bearing on the equipment's dependability, efficiency, and lifespan. Its principal strengths encompass robust load-bearing potential and influence resistance, high-precision transmission with low noise, resistance to fatigue and wear, adaptability to quite a number interface forms, and suitability for excessive environments.

Production Process:

Raw material inspection→Cutting→Forging→Normalizing→Rough turning→UT→Finished turning→Rolled spline→Gear milling→Carburizing and quenching→Tapping→Sandblasting→Thread turning→Cylindrical grinding→Gear grinding→Spline grinding→MT→CMM/GMM→Cleaning packaging

Before shipment, the merchandise will be cleaned, labeled, rust-proofed, and endure look inspection, and in the end packed and saved in the warehouse.

Company Strength:

The employer boasts 20 heavy forging manufacturing lines, basically made up of screw presses, die forging hammers, and massive ring rolling machines. Notably, its 25-ton die forging hammer manufacturing line ranks as China’s biggest hammer forging equipment. Additionally, it is outfitted with greater than 600 core machining and trying out devices, alongside with 10 of the world’s most superior Aichelin nitriding and carburizing lines. In the industry, it has the ability for "full-series, full-industry-chain" manufacturing and is capable to furnish clients with "one-stop" personalized offerings masking the whole lot from blanks to completed products.