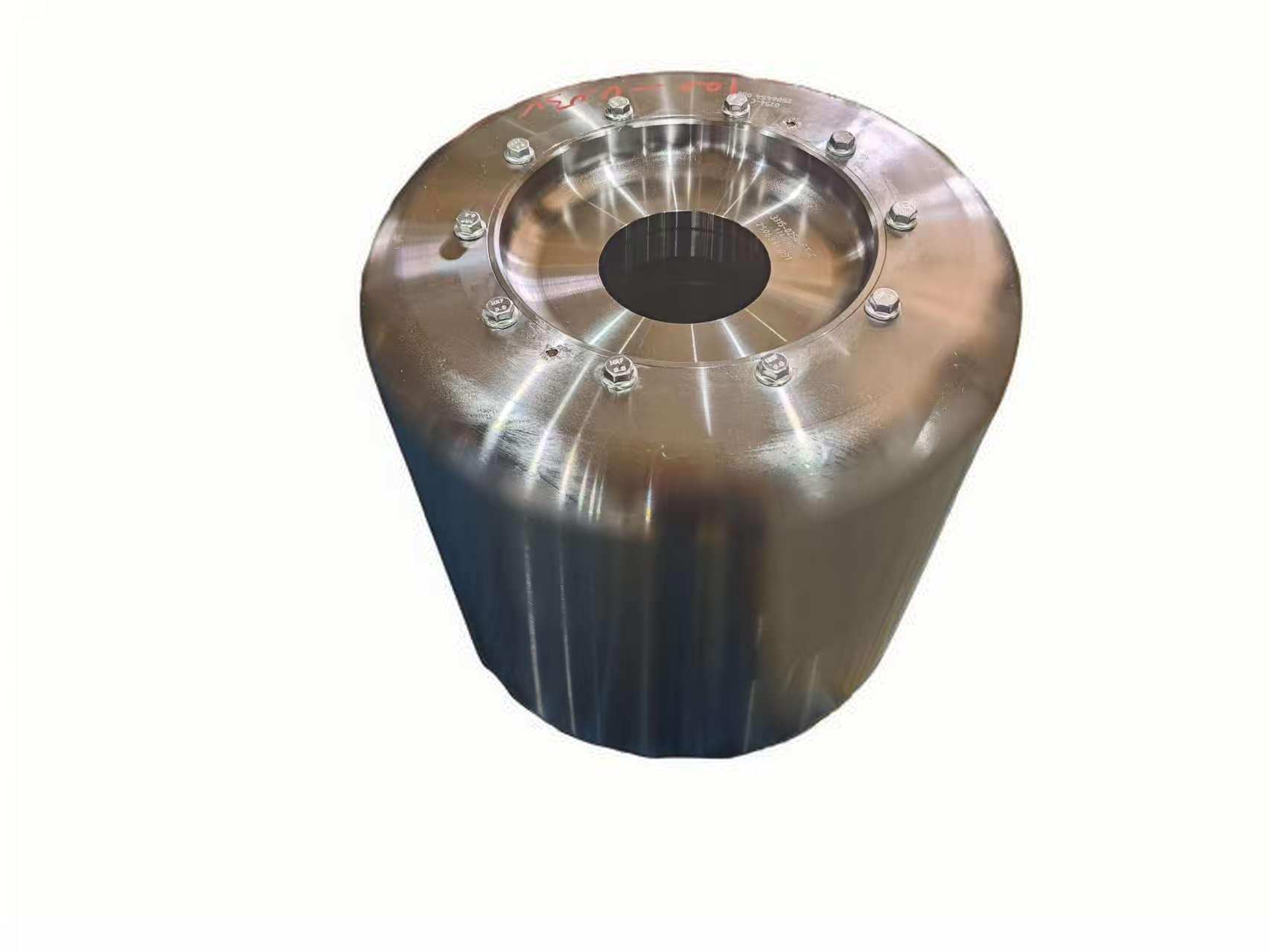

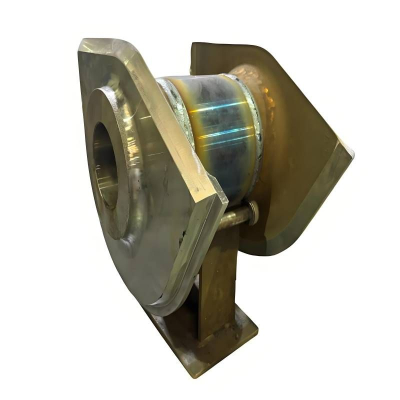

Precision engineered Forged Hubs

1.Material:42CrMo

2.Machining accuracy:±0.01mm

3.Mold opening cycle:About 45 days

4.Customization: We design and manufacture tailor-made products to your exact technical requirements.

5.Advantages:

Our strict process inspection ensures every product meets defect-free standards.

Streamlined one-stop processing delivers efficiency and cost savings.

From standard to custom, our wide product range solves all your needs.

6.Weight:Material usage and end-product weight will be derived from the Client’s provided drawings.

7.Craft:Forging

Product Introduction:

Forged hubs feature a dense molecular structure barring casting pores, achieving immoderate lightweighting that notably reduces the unsprung mass of new electricity vehicles, thereby enhancing differ and handling. Forged hubs can adapt to the core needs of electrification and meet warmness dissipation requirements. They can moreover tackle high-torque challenges with fantastically sturdy have an effect on resistance.

Product Advantages:

The hubs in the vicinity of new energy automobiles with their immoderate strength, lightweight, immoderate reliability and customized adaptability, have emerge as one of the core components of pressure buildings and chassis systems. The forging has no casting defects such as pores and shrinkage porosity inside, and has superb have an effect on resistance. It can face up to the affect of avenue bumps and potholes, reducing the hazard of tire blowouts and hub fractures. The hub forging manner adopts near-net-shape forming technology, reducing the waste of cutting processing and conforming to the "low-carbon and environmental protection" notion of the new energy industry. New power car hub forgings, by material upgrading, process innovation and structural optimization, have solved the bottlenecks of normal cast hubs in phrases of strength, weight and heat dissipation, and have come to be key factors the usage of the enchancment of new energy motors in the path of "high performance, prolonged differ and intelligence".

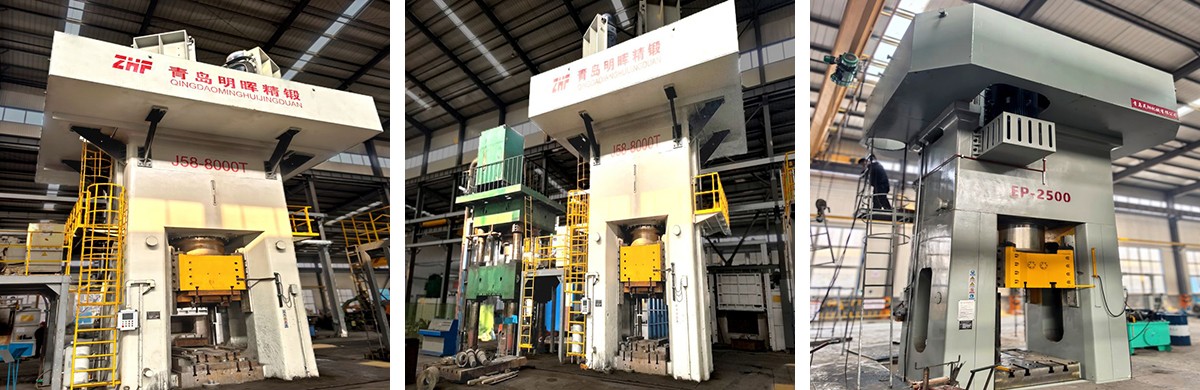

Production Process:

Raw material inspection → Cutting → Forging → Normalizing → Rough turning → UT → Quenched and tempered → Shot peening → MT → Finished turning → Drilling and Tapping → CMM/GMM → Cleaning packaging

Packaging and shipping:

Our professional crew enforces strict quality control for every and each and every order. Before shipment, all merchandise are fully cleaned, actually labeled, and dealt with with rust-proof coating. A whole seen inspection follows to assurance pinnacle charge quality. Finally, we cautiously bundle and save devices in our outfitted warehouse for on the spot dispatch readiness.

Company Strength:

The company's satisfactory administration constantly explores digitalization, engaging in on line administration of strategies such as hassle feedback, nonconformance review, quality traceability, and layered auditing. This has enhanced the standardization and timeliness of trouble handling.