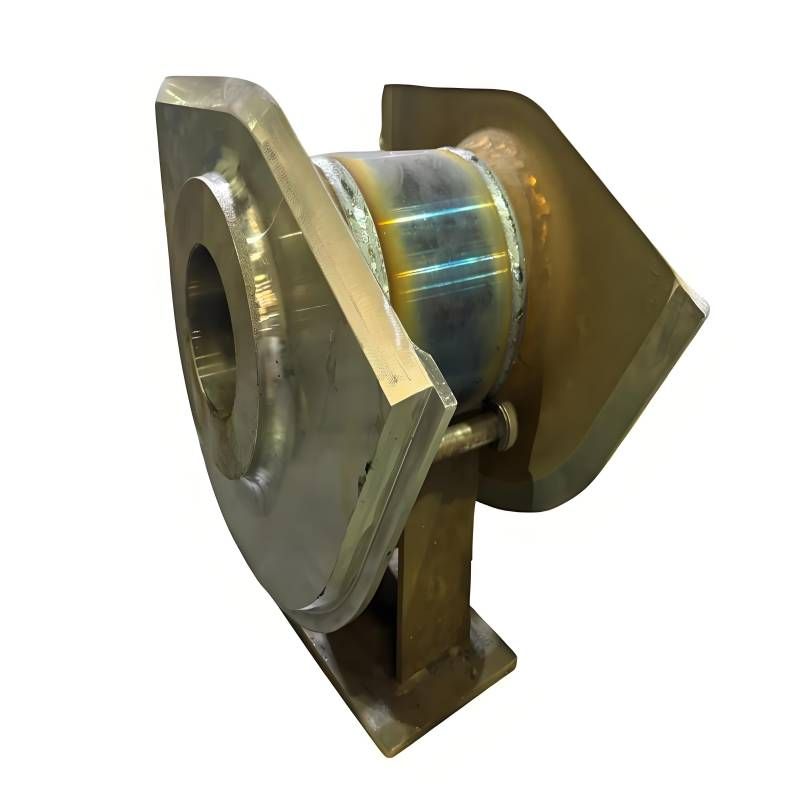

Excavator Forging Support Assembly

1.Material:35#(ASTM:1035 EN:C35E4 DIN:CK35),20MnMo,20#

2.Machining accuracy:±0.5mm

3.Customization: We design and manufacture tailor-made products to your exact technical requirements.

4.Advantages:

Our strict process inspection ensures every product meets defect-free standards.

Streamlined one-stop processing delivers efficiency and cost savings.

From standard to custom, our wide product range solves all your needs.

5.Weight:Material usage and end-product weight will be derived from the Client’s provided drawings.

6.Craft:Forging

7.Size:Execute custom orders with complete compliance to the drawings provided.

Product Introduction:

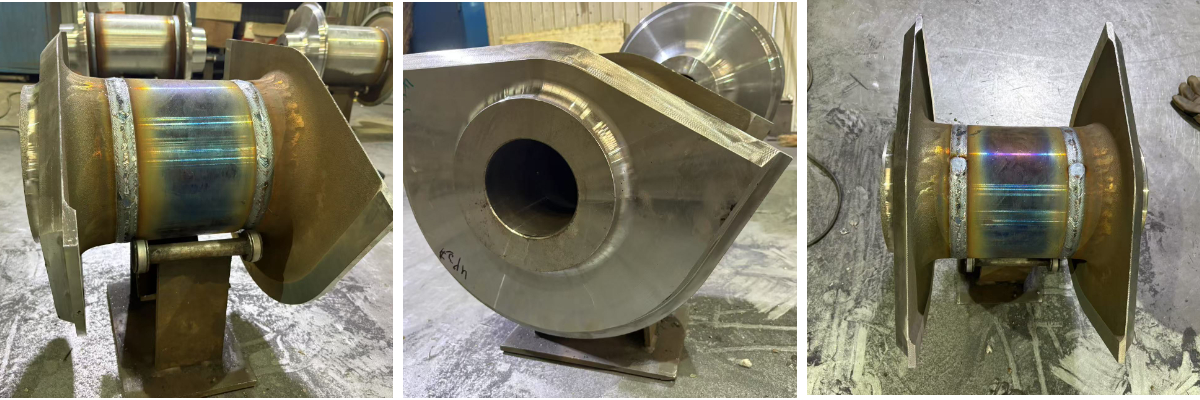

The support welded assembly (also known as the axle welded assembly, front support base welded assembly, or rear bracket welded assembly) of an excavator boom is a core load-bearing component that connects the boom and the arm. It plays a vital role in transmitting loads, ensuring stable balance, and enabling flexible movement. In the future, with the popularization of self-sensing lubrication structures and predictive maintenance technologies, the front support welded assembly will further develop towards an integrated model of "self-adaptation - self-repair - extended service life," becoming a core competitive feature of high-end excavators.

Product Advantages:

The support welded assembly of an excavator is a core load-bearing thing in the working computer of an excavator. Its product benefits are normally mirrored in cloth innovation, structural design, manufacturing manner and sensible optimization. The core benefits of the excavator increase and stick shaft seat meeting lie in: cloth upgrade, cast and quenched elements + wear-resistant coating, doubling the company life; structural innovation, adjustable size shape + modular indoors sleeve, bettering each adaptability and economy; manufacturing precision, robotic welding + positioning fixtures, making sure millimeter-level meeting accuracy; protection convenience, surfacing restore and modular replacement, notably reducing operation and renovation costs. Through the integration of assets science, structural mechanics and wise manufacturing technology, this meeting has completed a entire common general overall performance soar ahead in excessive strength, extended company existence and low maintenance, turning into a key facts for bettering the reliability of existing day excavator working devices.

Forgings + Pipe Fittings Assembly → Welding → Non-Destructive Testing → Cleaning & Packaging → Shipment

Packing and Shipping

Our team is committed to ensuring that every product meets the highest standards before it reaches our customers, and we have developed a comprehensive process to achieve this:

First, we will conduct a thorough cleaning of all products to remove any dust, debris, or residues accumulated during manufacturing or storage. Each item will then be clearly labeled with essential information such as product model number, batch code, and handling instructions, ensuring traceability and clarity throughout the supply chain. Following this, we will apply a professional rust-proofing treatment—using industry-grade coatings or protective films tailored to the product’s material—to safeguard against corrosion, especially for metal components, during transit and storage. Next, a meticulous quality inspection will be carried out. Our inspectors will examine every detail, from structural integrity and functional performance to surface finish and compliance with specifications, leaving no room for defects. Any issues identified will be promptly addressed to ensure only products in perfect condition proceed to the next stage. Finally, the verified products will be carefully packed using durable, custom-fit packaging materials to prevent damage during transportation. They will then be securely stored in our climate-controlled warehouse, where inventory is meticulously managed to maintain optimal conditions. This ensures that all items are kept in a state of full readiness, allowing for swift and efficient dispatch as soon as orders are confirmed. Through this rigorous sequence of steps, we guarantee that each product is delivered to our customers in pristine condition, ready for immediate use.

Company Strength:

With three decades of robust growth, the company has solidified its position as a leading player by strategically expanding into both domestic and global markets. Its product portfolio boasts wide-ranging applications across critical industries, including construction machinery, wind power generation, new energy vehicles, rail transit, petrochemicals, and mining equipment—testifying to its versatility and adaptability to diverse industrial needs. A key strength lies in its extensive international footprint: the company has forged deep-rooted partnerships with world-renowned enterprises spanning the United States, Canada, Germany, Italy, Belgium, Japan, and beyond. This global outreach is underscored by overseas sales accounting for over 50% of its total revenue, reflecting strong competitiveness in the international arena. Domestically, it has established strategic alliances with industry giants such as Zoomlion, XCMG, Sany, Lingsheng, CRRC, Nanjing Gear, and Zhuzhou Gear, further cementing its role as a trusted supplier to top-tier domestic manufacturers. Adding to its competitive edge, the company holds market-leading positions in core product segments: its planetary reducer core forgings and medium-to-large hook assemblies dominate the domestic market with the highest share, a testament to its technological prowess, product quality, and ability to meet the stringent demands of high-end industrial applications. This combination of global market penetration, strong partnerships with industry leaders, and market-leading product segments positions the company as a reliable, innovative force in the sector, well-equipped to drive future growth.