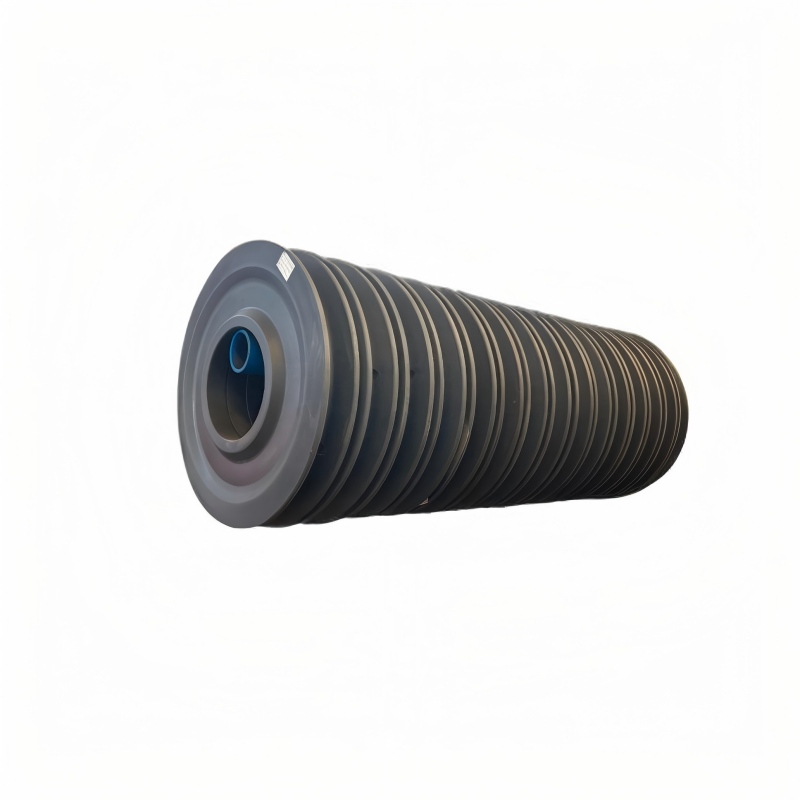

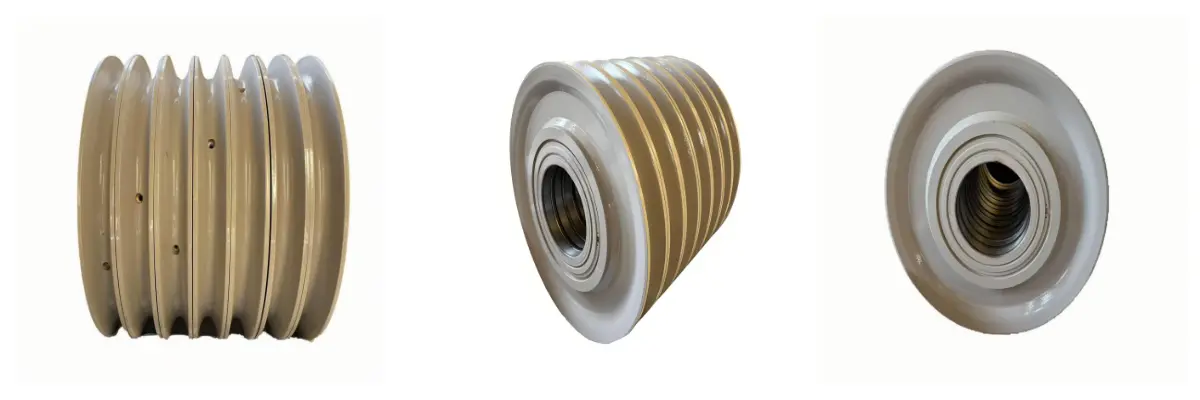

Tower Crane Pulley

1.Material:Q355B\Q355D\Q550D\35#

2.Machining accuracy:±0.1mm

3.Mold opening cycle:About 30 days

4.Customization: We design and manufacture tailor-made products to your exact technical requirements.

5.Advantages:

Our strict process inspection ensures every product meets defect-free standards.

Streamlined one-stop processing delivers efficiency and cost savings.

From standard to custom, our wide product range solves all your needs.

6.Craft: Forge

Product Introduction:

A key transmission part of the hook assembly, the crane pulley changes the force direction and lowers hoisting energy use through the principle of rolling friction. As a central component that enhances hoisting efficiency and stability, it is essential for various types of lifting equipment.

Product Advantages:

In crawler cranes, large-diameter, high-strength pulleys substantially boost lifting capacity. When paired with the crawler crane’s inherent stability, they reduce shaking and deformation during hoisting operations. The pulley shafts utilize large-diameter rolling or sliding bearings, which—combined with an automatic lubrication system—cut down on frictional losses and lower maintenance frequency. Polished pulley surfaces, paired with low-resistance bearings, minimize wire rope wear, enhance hoisting efficiency, and perform well in frequent lifting tasks and on-site relocation work. Pulley components can be replaced individually, leading to low maintenance costs; their integrated structure simplifies routine inspections (e.g., lubrication checks and wear detection) for quick maintenance.

Production Process:

Raw material inspection → Cutting → Rolling → Rough turning →Welding→ Deslagging→MT→ Finished turning→Drilling→ Tapping → CMM/GMM → Shot peening→Coating →Cleaning packaging

Packaging And Shipping:

Our team will make sure every product from the prior shipment goes through a thorough cleaning process. This process is designed to eliminate all dust, dirt, and any remaining residues. Next, each item will be labeled precisely with the correct product codes and detailed specifications. Following labeling, we will apply a high-quality rust-proof treatment. This treatment is critical to safeguarding the products against corrosion during both storage and transportation. Once these preparatory steps are finished, a careful inspection will be carried out. The inspection will confirm that all products meet quality standards, covering checks for defects, accurate labeling, and full coverage of the rust-proof treatment. Products that pass the inspection will then be carefully packed using top-tier protective materials to avoid any damage. Finally, the packed items will be stored in an orderly way in our warehouse. This organized storage ensures easy access and guarantees the products are fully ready for immediate shipment whenever needed.

Company Strength:

Over the past 30 years, our company has experienced vigorous growth and successfully expanded its presence in both domestic and global markets. Our high-performance products play a crucial role in key industries, ranging from construction machinery and wind power generation to new energy vehicles, rail transit, petrochemicals, and mining equipment.

Global Market Leadership

We have established solid partnerships with world-renowned enterprises in major industrial countries, including the United States, Canada, Germany, Italy, Belgium, and Japan. Currently, revenue from overseas customers accounts for more than 50% of our total sales, which serves as strong evidence of our competitive edge in the global market.

Strategic Domestic Alliances

In China, we maintain long-term strategic cooperation with leading heavy machinery and equipment manufacturers. These partners include industry giants such as Zoomlion, XCMG, Sany, Lingsheng, CRRC, Nanjing Gear, and Zhuzhou Gear. These collaborations have strengthened our position as a reliable supplier in the high-end equipment sector.

Market Dominance in Core Products

Planetary reducer core forgings: These are essential components for precision machinery and automation systems.

Medium-to-large lifting hook assemblies: These are widely used in heavy-load scenarios, such as cranes and industrial hoists.

Guided by continuous innovation, strict quality control, and a customer-focused approach, we remain dedicated to providing high-quality products and further solidifying our leading position in both domestic and global markets.