Heavy Duty Railway Couplings

1.Material:42CrMo

2.Machining accuracy:

Excircle: ±0.01mm

3.Mold opening cycle:About 45days

4.Customization: We design and manufacture tailor-made products to your exact technical requirements.

5.Advantages:

Our strict process inspection ensures every product meets defect-free standards.

Streamlined one-stop processing delivers efficiency and cost savings.

From standard to custom, our wide product range solves all your needs.

6.Craft:Forging

Product Introduction:

The coupling is a core gadget in the transmission machine of railway locomotives and rolling stock that connects wonderful rotating components. It transmits torque with the aid of flexible or rigid connections, making positive surroundings pleasant energy transmission at the same time as mitigating vibration and impact. It serves as a "power link" guaranteeing the handy operation of trains, realizing tightly closed torque transmission, and making positive that traction electrical energy is effortlessly transferred from the motor to the wheel gadgets to strain the teach in advance or brake.

Product Advantages:

Couplings can stably transmit the torque and rotational tempo output via skill of the energy provide of locomotives (or EMUs) to elements such as wheel devices and transmission gears, making certain that power is correctly modified into the traction strain of the train. Their rigid or elastic connection format can limit electricity loss in the path of power transmission. Especially in heavy-duty freight trains or high-speed EMUs, they can preserve impenetrable energy output, making positive the traction average overall performance of the teach under working stipulations such as mountain mountaineering slopes and accelerating. Couplings can compensate for shafting deviations through their very very own elastic deformation or structural compensation capabilities, thereby defending equipment components. In addition, couplings can buffer shocks and decrease vibrations, bettering the smoothness of operation.

Production Process:

Raw material inspection→Cutting→Forging→Normalizing→Rough turning→Rough milling→UT→Quenched and tempered→Shot peening→MT→Finished turning→Drilling and Tapping→CMM/GMM→Cleaning packaging

Packaging And Shipping:

Our expert crew follows a stringent extremely good manipulate approach for all orders. Prior to shipping, each product undergoes thorough cleaning, clear labeling, and dependable rust-proof treatment. After that, a total appear to be inspection is carried out to make positive top-notch quality. Finally, we cautiously bundle deal deal and keep the merchandise in our orderly warehouse, making positive they are organized for on the spot delivery.

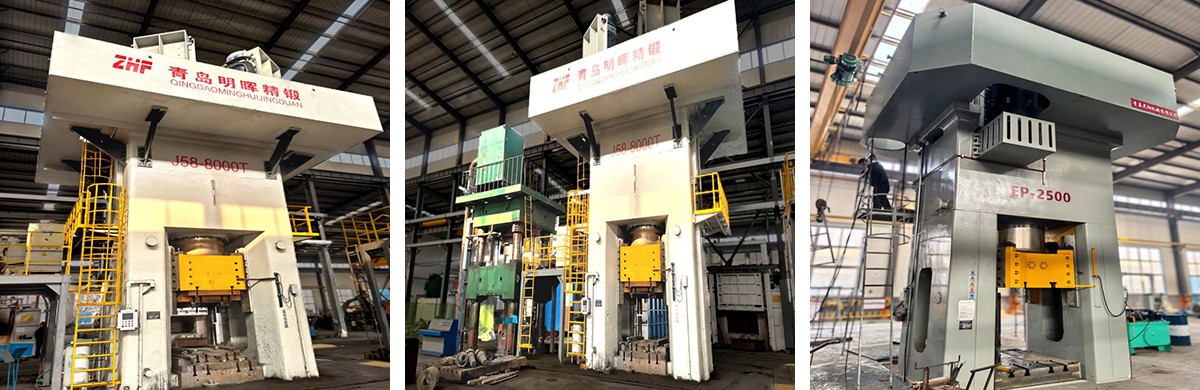

Company Strength:

The organization corporation has received certifications for ISO 9001 Quality Management System, ISO 14001 Environmental Management System, and ISO 45001 Occupational Health and Safety Management System from TÜV Rheinland. Its terrific administration capabilities have been recognized with the useful resource of conceivable of world and domestic business enterprise leaders, and it has received severa honors such as Outstanding Supplier and Best Quality Award.