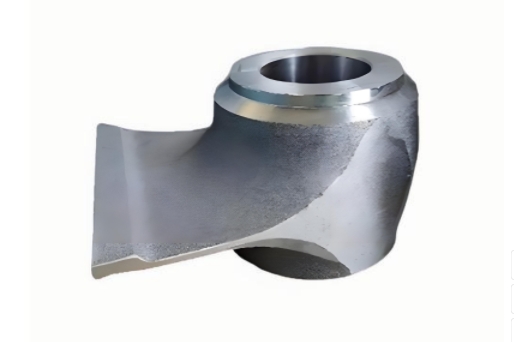

Premium Grade Front Support Shaft

1.Material:35#(ASTM:1035 EN:C35E4 DIN:CK35),20MnMo

2.Mold opening cycle:About 45 days

3.Craft:Forging

4.Advantages:

Our strict process inspection ensures every product meets defect-free standards.

Streamlined one-stop processing delivers efficiency and cost savings.

From standard to custom, our wide product range solves all your needs.

5.Weight/Size:Material usage and end-product weight will be derived from the Client’s provided drawings.

Product Introduction:

The front support seat of the upper frame of an excavator (also known as the front axle seat, front installation seat or rear hinge point) is the core load-bearing component that connects the frame and the boom. It plays an indispensable role in load transmission, ensuring stability and achieving flexible movement. With the popularization of self-sensing lubrication systems and predictive maintenance technologies, the front support seat will develop towards an integrated system of "self-adaptation → self-repair → extended service life", becoming one of the core competitive advantages of high-end excavators.

Product Advantages:

The advantages of its products are mainly reflected in four aspects: structural innovation, material and process, safety and ease of use, and multi-scenario adaptability. The following is a detailed explanation from four dimensions: mechanical structure, core advantages, intelligent functions, and full life cycle cost:

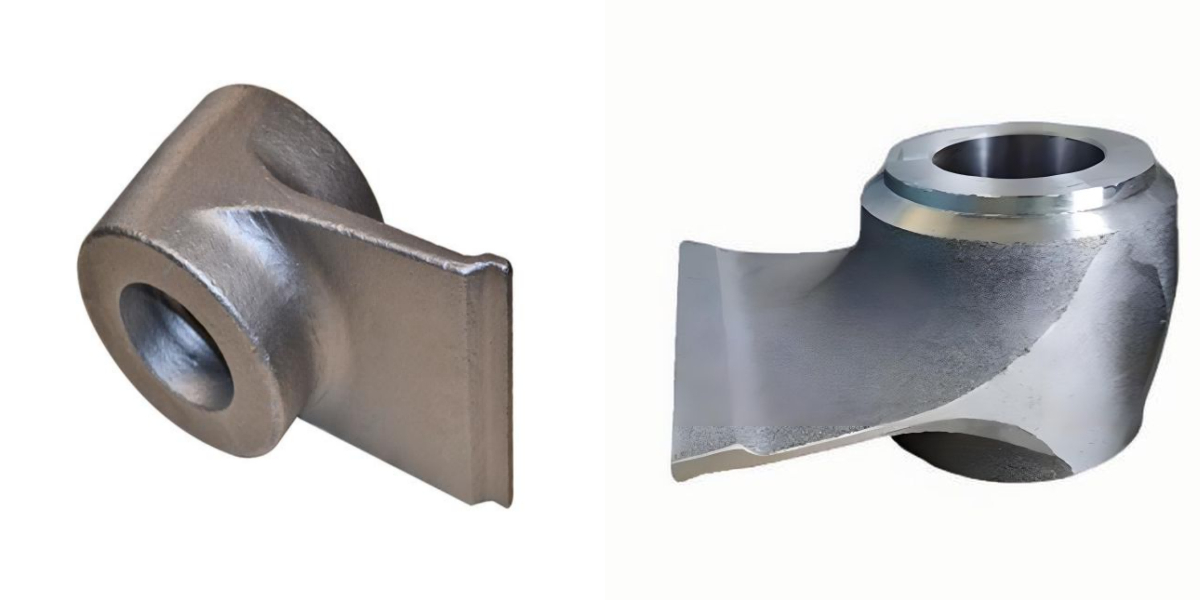

I. Characteristics of Mechanical Structure

The front support seat of the excavator is located at the front end of the boom and is hinged to the boom through a pin shaft. During operation, it can transfer the working load (such as bucket resistance, vibration torque, etc.) to the boom and chassis structure. Meanwhile, as the rotating axis of the bucket rod, it can precisely control the depth and Angle of excavation.

Ii. Core Advantages

The core advantage of the front support seat of the excavator boom lies in its ultra-high reliability structure:

The anti-offset load design and the overall forging process fundamentally solve the problem of component cracking.

Integrated design, anti-offset load reinforcement structure, centrally symmetrical support, reinforcement plate layout, adjustable design and positioning anti-offset characteristics jointly ensure the high reliability of the components.

Iii. Intelligent Functions

Adjustable in length and Angle, it can adapt to various working scenarios.

Built-in sensors enable predictive maintenance and provide early warnings of potential faults.

Iv. Full Life Cycle Cost Optimization

By adopting a modular vulnerable parts design and combining it with a self-lubricating structure, maintenance costs can be reduced by 40%.

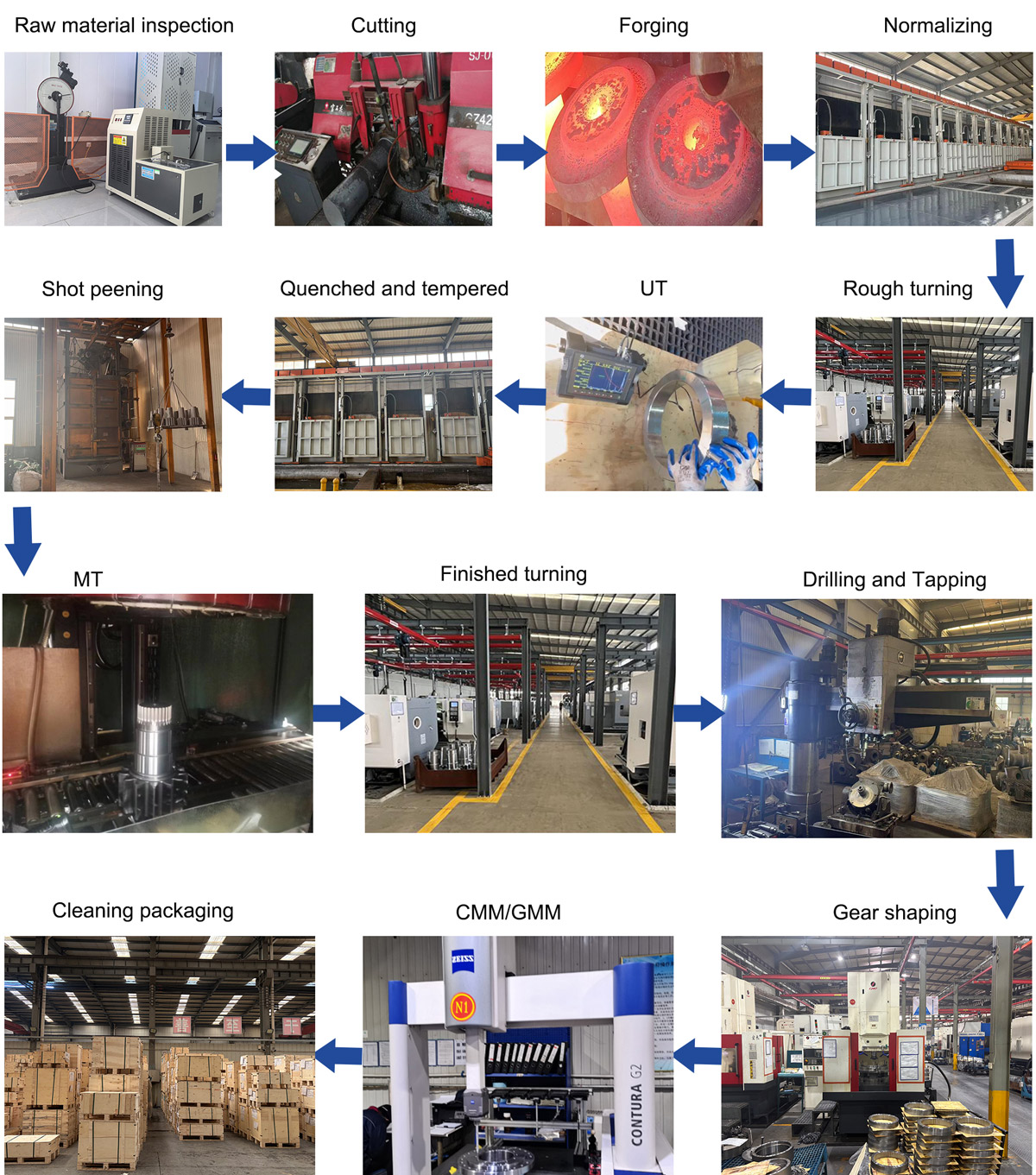

Production Process:

Raw Material Inspection → Cutting → Forging → Heat Treatment/Tempering → Shot Blasting → Rough Machining → Ultrasonic Testing (UT) → Final Inspection → Cleaning Packaging

Packaging and Shipping

Prior to shipment, our team will carry out a comprehensive pre-delivery preparation process for all products: first, each item will undergo thorough cleaning, clear labeling, and professional rust-preventive treatment to ensure its integrity during transit. Following this, we will conduct a meticulous visual inspection with strict standards, leaving no detail unchecked to confirm that every product meets our flawless quality requirements. Once the inspection is passed, we will then proceed with professional packaging for each product and store them in our well-organized warehouse. This ensures that all goods are kept in optimal condition and ready for immediate dispatch whenever needed.

Company Strength:

After 30 years of steady development, the enterprise has actively expanded into various domestic and international markets. Its products are widely used in multiple fields such as construction machinery, wind power generation, new energy vehicles, rail transit, petrochemicals, and mining machinery. At present, the enterprise has established in-depth cooperative relations with many international well-known enterprises in the United States, Canada, Germany, Italy, Belgium, Japan and other countries, and the sales volume of overseas customers accounts for more than 50%. At the same time, it has also formed long-term strategic cooperative partnerships with domestic mainstream high-end equipment manufacturers such as Zoomlion, XCMG, Sany, Lingong, CRRC, Nanjing Gear, and Zhuzhou Gear. In terms of product competitiveness, its domestic market share of core forgings for planetary reducers and large and medium-sized hook assemblies has remained the top.