Sprockets Wheel For Petrochemical

1.Material:42CrMo

2.Machining accuracy:

Excircle: ±0.01mm

3.Mold opening cycle:About 45days

4.Customization: We design and manufacture tailor-made products to your exact technical requirements.

5.Advantages:

Our strict process inspection ensures every product meets defect-free standards.

Streamlined one-stop processing delivers efficiency and cost savings.

From standard to custom, our wide product range solves all your needs.

6.Craft:Forging

Product Introduction:

The sprocket wheel is a key difficulty in the electricity transmission laptop of the petrochemical industry. Its basic overall performance is without delay related to the continuity and safety of the manufacturing process, and it is an fundamental hyperlink to make sure the impenetrable operation of petrochemical plants. The core function of the sprocket is to convert the rotational motion of the driving device (such as a motor or hydraulic motor) into the linear or cyclic motion of the chain by the special meshing of the sprocket enamel with the chain, thereby using the operation of load-carrying elements such as conveyor belts and stirring shafts.

Product Advantages:

Sprockets are oftentimes made of high-strength metallic and undergo warmness treatment (quenching, carburizing) to embellish ground hardness and core toughness, enabling them to stand up to massive torque and have an impact on forces. Sprockets can adapt to complex working conditions with immoderate and constant transmission efficiency, making certain continuous production. In the petrochemical industry, sprockets, with advantages such as immoderate load-bearing capacity, resistance to harsh environments, immoderate efficiency, compact structure, and accessible maintenance, have come to be core factors for making positive the the use of of heavy-duty equipment and fabric conveying. Their general overall performance is at as soon as related to manufacturing safety, continuity, and economy, making them critical key components in petrochemical transmission systems.

Production Process:

Raw material inspection→Cutting→Forging→Normalizing→Rough turning→Rough milling→UT→Quenched and tempered→Shot peening→MT→Finished turning→Finished milling→Drilling and Tapping→CMM/GMM→Cleaning packaging

Packaging And Shipping:

Our dedicated crew implements rigorous great control protocols for every order. Prior to shipment, all merchandise undergo:

Thorough cleansing to dispose of manufacturing residues;

Clear labeling for handy identification and traceability;

Industrial-grade rust-proof coating for long-term protection.

A complete seen inspection is then carried out to make sure flawless quality. Finally, merchandise are cautiously packaged and saved in our geared up warehouse, geared up for on the spot dispatch.

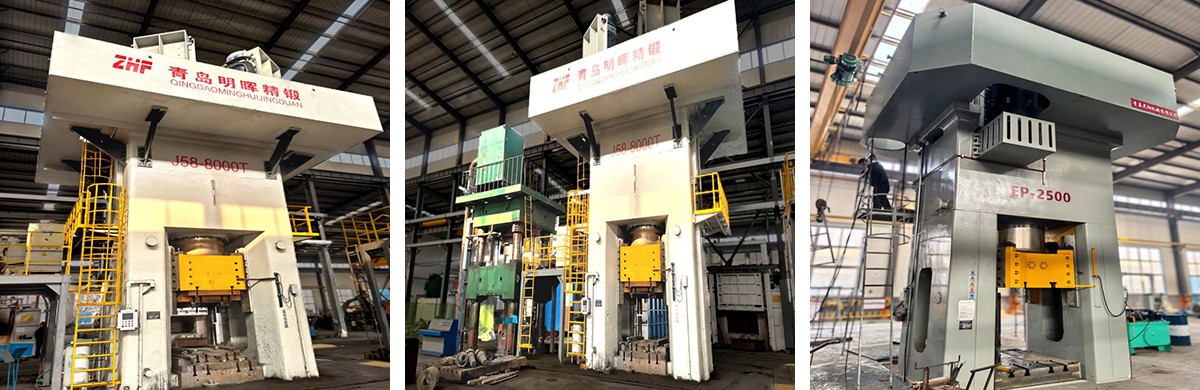

Company Strength:

The company's super administration constantly explores digitalization, carrying out on line administration of techniques such as hassle feedback, nonconformance review, superb traceability, and layered auditing. This has higher terrific the standardization and timeliness of problem handling.