What's the point of a planetary gearbox?

What's the point of a planetary gearbox?

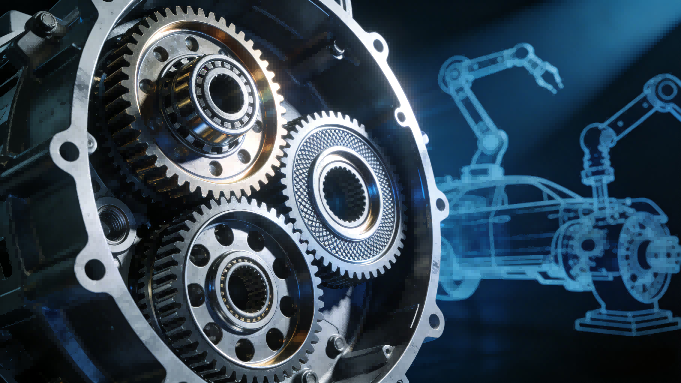

In the fields of industrial transmission and new energy vehicle power systems, planetary gearboxes have long been core transmission components. However, their unique transmission logic and core values still raise doubts among many newcomers and even practitioners in the industry: What exactly is the significance of planetary gearboxes? What advantages does it have that make it a standard configuration for many high-precision devices? And how do the forging process and planetary carrier determine the performance limit of a planetary gearbox? This article will comprehensively disassemble the significance of planetary gearbox from three dimensions: core values, key components, and process empowerment.

I. Core Values of planetary gearbox: Achieving high torque in a small size and adapting to precise transmission in various scenarios

The reason why planetary gearboxes are widely used in new energy vehicle reducers, industrial robot joints, construction machinery winches and other equipment lies in their unique planetary transmission structure, which can achieve four core values that are difficult for traditional gearboxes to reach:

It combines a high transmission ratio with a compact volume

To achieve a large transmission ratio, traditional fixed-axis gearboxes often require the superposition of multiple gears, resulting in an overall large volume and excessive weight. The planetary gearbox, through the coordinated operation of the sun gear, planet gear, internal gear ring and planetary carrier, can achieve a transmission ratio of 3 to 10 in a single stage. When multiple stages are combined, the transmission ratio can easily exceed 100, and its overall volume is only 1/3 to 1/2 of that of a fixed-axis gearbox of the same specification. It is perfectly adapted to scenarios that are sensitive to space and weight, such as new energy vehicles and precision robots.

High torque density and strong load-bearing capacity

The structure where planetary gears revolve around the sun gear evenly distributes the load across multiple planetary gears. Compared with the traditional gearbox's single-gear force-bearing mode, the torque carrying capacity of planetary gearboxes is increased several times, enabling them to output extremely large torque within a limited space. It is the preferred transmission choice for heavy-duty equipment such as heavy construction machinery and new energy commercial vehicles.

It features high transmission efficiency and smooth operation

The symmetrical arrangement of multiple planetary gears effectively offsets the radial force during the transmission process, reduces the vibration and noise of gear meshing. Meanwhile, its transmission path is short and the power distribution is reasonable. The overall transmission efficiency can reach 95%-98%, which is much higher than that of some traditional gearboxes. It can not only reduce energy loss but also improve the stability of equipment operation.

High adaptability, supporting multi-condition operation

Whether it is the frequent start and stop of new energy vehicles, the high-precision positioning of industrial robots, or the harsh working conditions of construction machinery, planetary gearbox can adapt to different demands through structural adjustments. For instance, in the reducers of new energy vehicles, it can achieve stepless power distribution and speed regulation, and in the joints of robots, it can ensure transmission accuracy at the micrometer level.

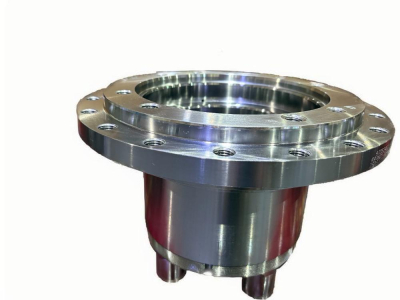

Ii. planetary carrier: The "power hub" of planetary gearboxes, where structural strength determines transmission stability

Among the core components of planetary gearbox, the planetary carrier is undoubtedly the "power hub". It is not only the installation carrier of the planetary gear, undertaking the role of fixing the planetary gear shaft and transmitting power, but also needs to withstand the centrifugal force and torque load generated by the planetary gear's revolution. Its structural strength and precision directly affect the transmission efficiency and service life of the entire gearbox.

The core function of planetary carrier

The planetary carrier connects the planetary gears with the output shaft, converting the orbital power of the planetary gears into the rotational power of the output shaft, while ensuring the synchronous operation of multiple planetary gears and guaranteeing the even distribution of loads. Once the planetary carrier deforms or breaks, it will directly cause misalignment of the planetary gear meshing, leading to gearbox jamming, sudden torque drop and even overall machine failure.

The performance pain points of planetary carrier

In high-torque and high-frequency operation scenarios, planetary carriers need to simultaneously withstand combined radial, axial and torsional stresses. If conventional casting processes or low-strength materials are used, problems such as stress concentration and fatigue cracking are highly likely to occur, especially in high-load equipment like new energy vehicle reducers. The reliability of planetary carriers is directly related to the driving safety of the entire vehicle.

Iii.Process Empowerment: Enhancing planetary carrier and Unlocking High Performance of planetary Gearboxes

To address the performance bottleneck of planetary carriers, the forging process has become a standard technology for high-end planetary gearboxes. Compared with traditional casting processes, the performance improvement brought by forging is reflected in three core dimensions:

Dense metal structure enhances structural strength

Forging process, by applying high temperature and high pressure to metal billets, refines and closely arranges the internal grains, completely eliminating defects such as pores and sand holes that are prone to occur in casting processes. The forged planetary carrier has a tensile strength of 800-1200 mpa, which is more than twice that of castings. It can easily withstand stress impacts under high-torque conditions, significantly reducing the risk of deformation and fracture.

Lightweight design reduces overall energy consumption

Forging processes can precisely reduce the structural weight of planetary carriers while ensuring their strength. By optimizing the profile and thinning the wall thickness of non-stressed parts, a lightweight effect of 20% to 30% lighter than that of castings can be achieved. This can effectively reduce the unsprung mass of the entire vehicle and increase the driving range for new energy vehicles. For industrial robots, it can reduce the load on joints and enhance the flexibility of movement.

High dimensional accuracy ensures meshing stability

Precision forging technology can achieve near-net-shape planetary carriers, and only a small amount of machining is required subsequently to meet the assembly accuracy requirements. The coaxiality and hole diameter tolerance of the planetary gear shaft holes can be controlled at the micrometer level, ensuring the precise meshing of the planetary gear with the sun gear and the internal gear ring, and avoiding the decrease in transmission efficiency and increase in noise caused by component misalignment.

Take the planetary carrier of new energy vehicle reducers as an example. The products made by forging process have a transmission efficiency decline of only 2% in the 100,000-kilometer durability test of the entire vehicle, while the decline of castings can reach over 8%. In the torque impact test, the forged planetary carrier can withstand an instantaneous impact of three times the rated torque without damage, fully demonstrating the empowering value of the forging process to the performance of planetary gearboxes.

IV. Key Points for Selecting planetary Gearboxes: Look at the planetary carrier's craftsmanship. Choosing forged products is more reliable

For equipment manufacturers and purchasers, when judging the quality of a planetary gearbox, the key lies in the manufacturing process of its planetary carrier:

For planetary carriers that prioritize forging processes, it is necessary to confirm that the supplier has a complete forging, heat treatment, and precision processing production line, and that the products have passed industry certifications such as ISO/TS16949.

Verify the core performance parameters, with a focus on indicators such as the tensile strength, fatigue life, and dimensional tolerance of the planetary carrier, to ensure that they are compatible with the actual working conditions of the equipment.

Focusing on customization capabilities, high-quality planetary gearbox suppliers can customize the structure and materials of forged planetary carriers according to the torque and speed requirements of the equipment, achieving the optimal match of the transmission system.

Summary

The core value of planetary gearboxes lies in their ability to achieve precise transmission with high gear ratios and large torques in a compact size. As the "power hub", the performance of planetary carriers is the key to determining the reliability of gearboxes. The forging process unlocks higher performance limits for planetary gearboxes by enhancing their structural strength, lightweight level and precision, enabling them to meet the demanding requirements of various fields such as new energy vehicles, industrial robots and construction machinery.

Whether it is the selection of vehicle manufacturers, the upgrading of industrial equipment, or the procurement of transmission components, only by recognizing the core value of planetary gearboxes and identifying the forging process of planetary carriers can one select a high-performance transmission solution that truly suits the working conditions.