How to choose Electric Car Base? A comprehensive guide from the base to forged rims

How to choose Electric Car Base? A comprehensive guide from the base to forged rims

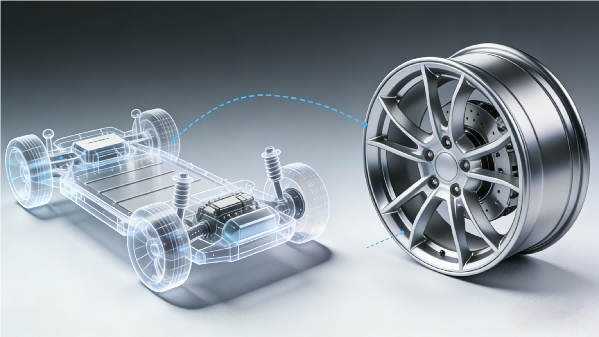

With the vigorous development of the new energy vehicle market, more and more consumers, when choosing electric vehicles, are beginning to shift from merely focusing on range and intelligent configuration to a deeper consideration of the vehicle's infrastructure. Among them, the electric vehicle base, as the core load-bearing component of the entire vehicle, directly determines the stability, safety and driving experience of the vehicle. The type of wheel hub paired with the base, especially the quality of the forged wheel hub, is a key factor affecting the overall performance of the vehicle. This article will break down the logic of choosing an electric vehicle base for you, from base selection to wheel hub configuration.

I. Clarify the core selection dimensions of electric car base

The essence of the electric car base is an integrated architecture of the vehicle's chassis and battery support. It is not only the "supporter" of core components such as batteries and motors, but also the first line of defense for the safety of the entire vehicle. When making a choice, the following three core dimensions should be given particular attention:

The structural strength and material of the base

High-quality electric vehicle bases are made of lightweight and highly rigid materials such as high-strength steel and aluminum alloy. Some high-end models also incorporate carbon fiber composite materials. This type of base can effectively disperse the impact force during a collision and protect the integrity of the battery pack. Meanwhile, the base made by the integrated die-casting process has more advantages in torsional resistance and sealing compared with the traditional spliced base, which can reduce the risk of water ingress and short circuit in the battery.

The spatial adaptability of the base

The design of the base directly affects the interior space and battery layout of the vehicle. Large-sized batteries require the base to have a reasonable space planning, ensuring that the battery capacity meets the driving range requirements while not overly occupying the interior space for passengers. In addition, the ground clearance of the base also needs to take into account both urban commuting and light road conditions to prevent scratches caused by a low chassis, which could affect the service life of the base and the battery.

The compatibility of the base with the entire vehicle system

The base of an electric vehicle needs to be highly compatible with the motor, electronic control system and suspension system. For instance, the base of rear-wheel drive models will optimize the weight distribution for the motor layout, while four-wheel drive models need to balance the torque distribution between the front and rear motors. A highly compatible base can enhance the vehicle's handling response speed, reduce energy loss, and indirectly improve the range performance.

Ii. Indispensable related components: The compatibility logic between the base and the hub

Many people tend to overlook the matching degree between the base and the wheel hub when choosing an electric vehicle. However, as the only part of the vehicle that comes into contact with the ground, the quality and specification of the wheel hub will directly affect the force state of the base. Forged wheel hubs are the preferred choice for high-end models and performance enthusiasts. Specifically, the compatibility can be judged from these two points:

The matching of wheel hub material with the load-bearing capacity of the base

Although ordinary cast wheels have a lower cost, they are far inferior to forged wheels in terms of load-bearing capacity and impact resistance. Forged wheel hubs are formed through high-pressure forging technology, with a higher material density. Under the same size, they are about 30% lighter than cast wheel hubs and have a stronger load-bearing capacity. For electric vehicles, the battery itself has already increased the load on the base. Paired with lightweight forged wheels, it can effectively reduce the load-bearing pressure on the base, lower energy consumption while enhancing the response flexibility of the chassis.

The coordination between the hub specification and the base suspension

The size and J value (hub width) of the wheel hub need to be compatible with the suspension system of the base. Excessively large wheel hubs will increase the unsprung mass, add to the burden on the base suspension, lead to a decline in shock absorption, and affect the driving and riding comfort. A wheel hub that is too small will limit the installation space of the braking system and fail to fully utilize the handling performance of the base. It is recommended to select wheels based on the original factory parameters of the vehicle model. If performance upgrades are pursued, it is advisable to give priority to choosing compatible forged wheels, which can enhance the overall sporty attributes of the vehicle without changing the suspension geometry.

Iii. A guide to avoiding pitfalls when purchasing electric car base

Don't blindly pursue "big battery + hard base"

Some consumers believe that the larger the battery capacity and the thicker the base, the safer it is. However, this is not the case. An overly thick base will increase the vehicle's own weight, which in turn will reduce its range and handling. However, large batteries that are beyond the vehicle's compatibility range may disrupt the weight balance of the base and increase safety risks during driving.

Beware of the combination trap of "low-end base + high-end wheel hub"

If the structural strength of the vehicle base itself is insufficient, even if it is equipped with high-performance forged wheels, the advantages of the wheels cannot be brought into full play. For instance, if the base suspension of low-end models is tuned to be too soft and large-sized forged wheels are forcibly replaced, it will lead to insufficient support of the chassis, causing problems such as high-speed drifting and severe roll when cornering, and may even damage the suspension connection parts of the base.

Give priority to choosing the original factory-compatible base and wheel hub combination

Before leaving the factory, car manufacturers will conduct multiple rounds of compatibility tests on the base and rims. The rims provided by the original factory (especially the original factory forged rims) can best fit the force logic of the base. If modification is required, it is essential to choose a qualified brand. After modification, the suspension parameters of the base need to be recalibrated to ensure the stability of the entire vehicle.

Iv. Summary: The core principles of choosing the right electric car base

The essence of choosing Electric Car Base is to balance the three major demands of "safety, range and handling", while taking into account the compatibility of the base with related components such as forged wheels. A high-quality base is the "safety cornerstone" of the entire vehicle, while lightweight and high-rigidity forged wheels are the "bonus points" for the base's performance. It is recommended that when making a purchase, you first confirm the core material and structure of the base, and then match the appropriate wheels according to the vehicle model positioning. Only in this way can the chassis performance and driving experience of the electric vehicle reach the optimal state.