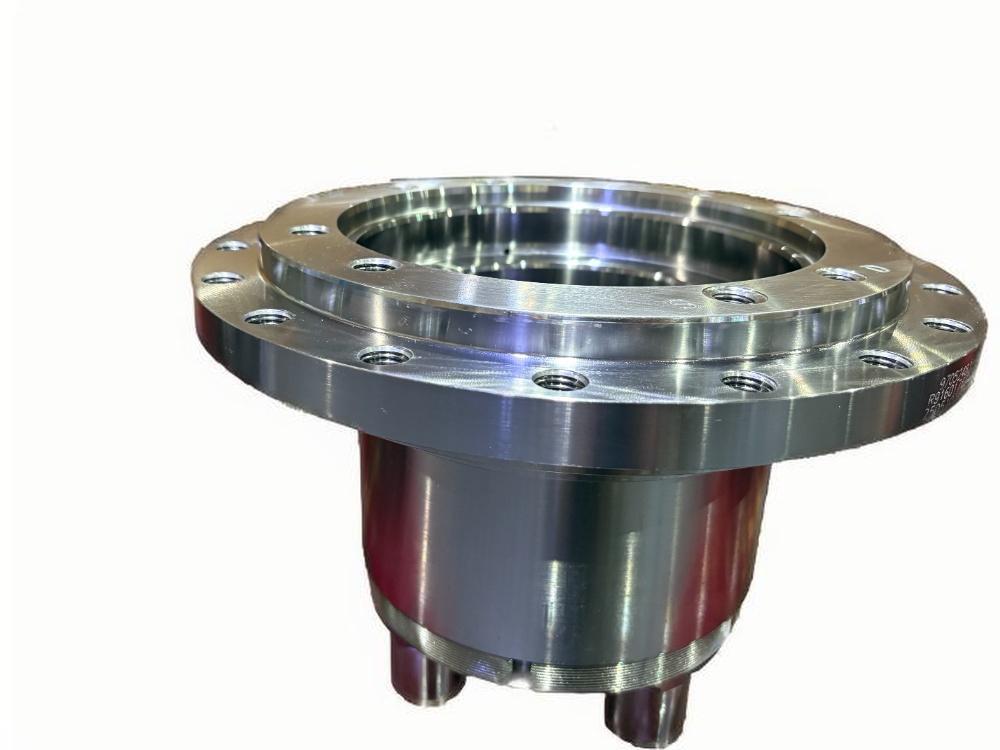

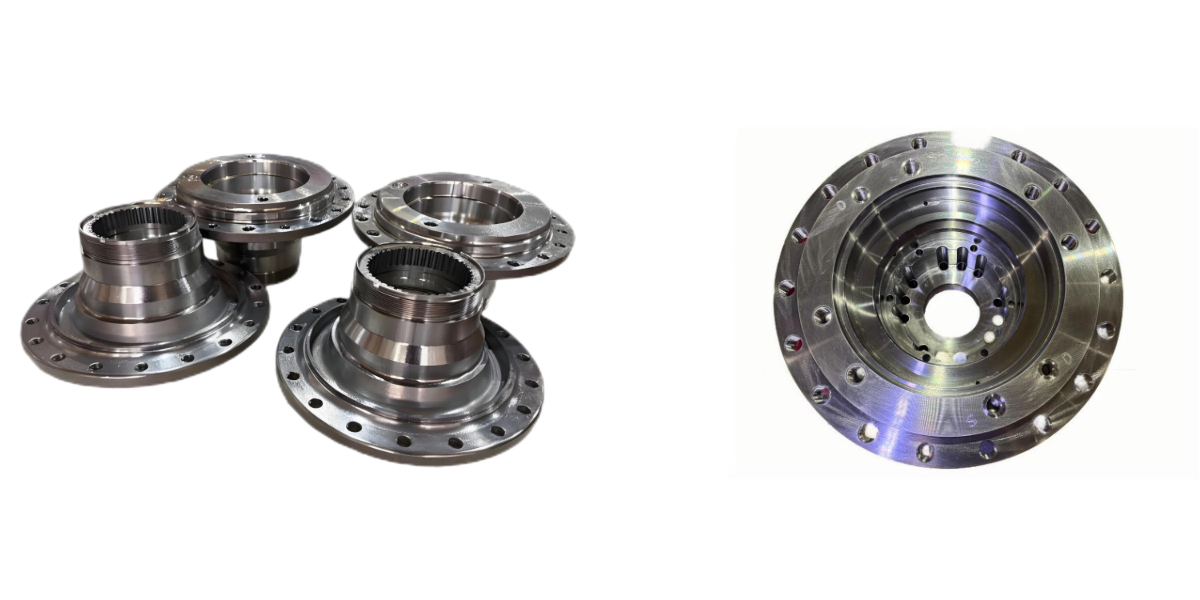

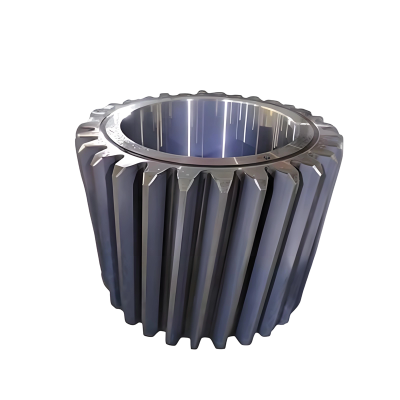

Planetary reducer Spindle

1.Material:42CrMo/40Cr

2.Machining accuracy:±0.01mm

3.Mold opening cycle:About 45 days

4.Craft:Forging

5.Advantages:

Our strict process inspection ensures every product meets defect-free standards.

Streamlined one-stop processing delivers efficiency and cost savings.

From standard to custom, our wide product range solves all your needs.

6.Weight:Material usage and end-product weight will be derived from the Client’s provided drawings.

Product Introduction:

Support shafts are foundational components in mechanical systems, tasked with securing rotating parts, transmitting loads, maintaining motion precision, and reducing friction. As cylindrical parts, they typically integrate with bearings, seals, and lubrication systems to form functional support units—acting as the "mechanical backbone" of industrial equipment.

Produt Advantages:

As core mechanical components, support shafts excel in structural design, material performance, functionality, and cost-effectiveness: they offer high load-bearing capacity and stability, and compact, integrated design . Driven by Industry 4.0, their future innovations include carbon fiber materials , embedded sensors , and laser cladding remanufacturing —all to keep powering high-end equipment development.

Production Process:

Raw material inspection→ Cutting→ Forging → Normalizing → Rough turning → UT → Quenched and tempered → Shot peening → MT → Finished turning → Drilling and Tapping → Shaping → CMM/GMM → Cleaning packaging

Packaging and Shipping

To ensure your products’ quality, integrity, and timely delivery, our team will execute a strict multi-step pre-shipment process: first, we’ll fully pre-treat products (clean to remove residues, apply material/usage-specific rust-proofing like anti-rust oil, and label with key info such as model/batch codes); next, our QC team will rigorously inspect each treated item (verifying rust-proofing effectiveness, label accuracy, and compliance with standards, flagging failures for rework/replacement); finally, we’ll package passed products with industry-grade shock-absorbent/waterproof materials (tailored to size/weight/fragility) and store them in a climate-controlled warehouse (with real-time inventory tracking) until dispatch per your instructions.

Company Strength:

With 30 years of dynamic development, the company has solidified its foothold in both domestic and global markets, boasting a product range that serves high-priority sectors—from construction machinery and wind power to new energy vehicles, rail transit, petrochemicals, and mining machinery—addressing each industry’s critical operational demands. Globally, it has built deep partnerships with renowned enterprises across the U.S., Canada, Germany, Italy, Belgium, and Japan, a reach that translates to overseas revenue making up over 50% of its annual total—proof of its strong standing in international competition. Domestically, it has forged strategic ties with top-tier high-end equipment makers like Zoomlion, XCMG, Sany, Lingsheng, CRRC, Nanjing Gear, and Zhuzhou Gear, boosting supply chain integration and driving joint R&D innovation. A key marker of its strength lies in its core products: planetary reducer core forgings and medium-to-large lifting hook assemblies. Both hold the No.1 domestic market share, cementing the company’s leadership in China’s high-end equipment component sector.