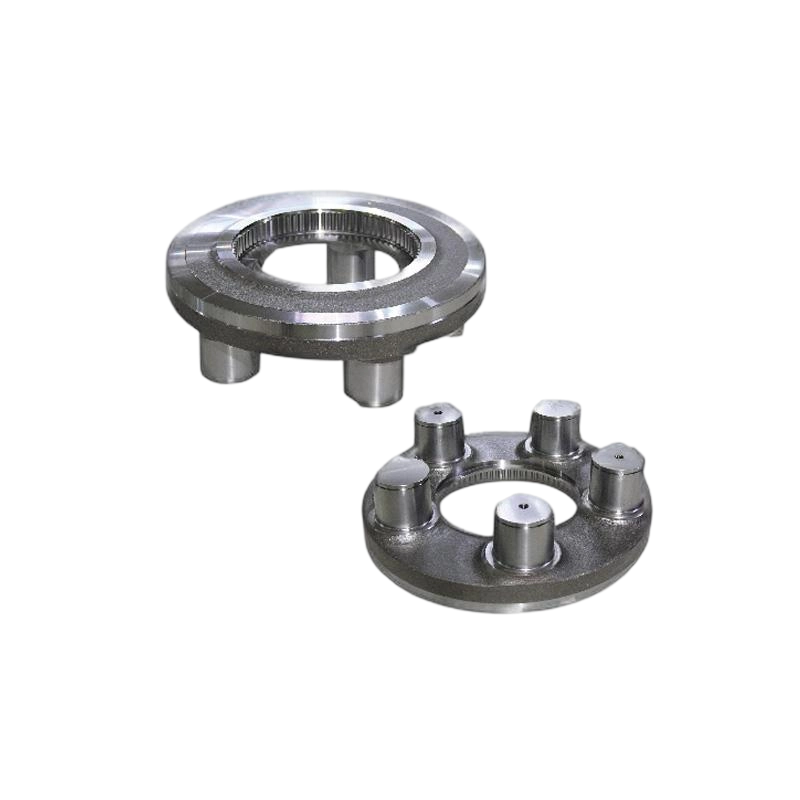

Corrosion Resistant Planetary Carrier

1.Material:42CrMo/40Cr

2.Machining accuracy:

Excircle: ±0.01mm

Tooth accuracy: Grade 5

3.Mold opening cycle:About 45 days

4.Customization: Provide custom-engineered solutions according to provided technical drawings.

5.Advantages:

Full-process inspection

Full-process processing capability

Full-range products

6.Weight/Size:Execute custom orders with 100% drawing compliance

7.Craft:Forging

Product Introduction:

The planetary carrier in a planetary gearbox is one of the core components of the planetary gear transmission system. It derives its name from the structure that resembles planets orbiting a star. Comprising a frame body, bearing mounting positions, and gear connection parts, it is typically crafted from high-strength alloy steel through forging and machining processes. Its structural design balances strength, rigidity, and lightweight requirements to ensure stable operation under complex working conditions.

Product Advantages:

The planet carrier is a core component of the planetary gear transmission system. It features a compact structure, high space efficiency, strong load-bearing capacity, smooth transmission, high transmission efficiency, flexible installation, convenient maintenance, strong environmental adaptability, wide compatibility with working conditions, and a wide range of application scenarios. It plays an irreplaceable role, especially in fields such as construction machinery, automotive, and aerospace.

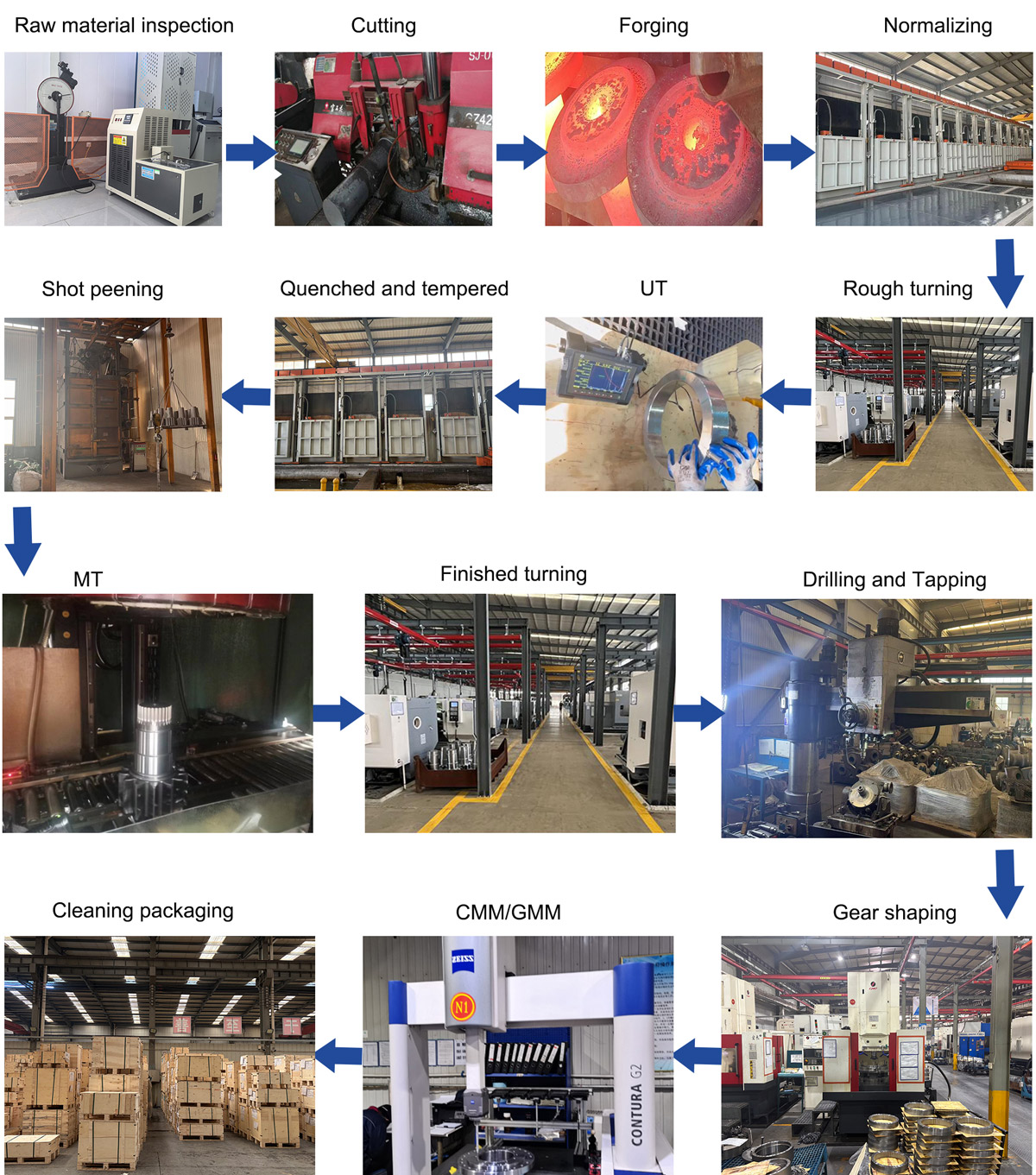

Production Process:

Raw material inspection → Cutting → Forging → Normalizing → Rough turning → UT → Quenched and tempered → Shot peening → MT → Finished turning → Drilling and Tapping → Shaping → CMM/GMM → Cleaning packaging

Our team will:

Clean, label, and apply rust-proofing to all products before shipment;

Perform a meticulous appearance inspection;

Finally pack the products and store them in our warehouse, ensuring readiness for dispatch.

Company Strength:

Over the past 30 years of vigorous development, the company has aggressively expanded into both domestic and international markets. Its products are widely used in fields such as construction machinery, wind power generation, new energy vehicles, rail transit, petrochemicals, and mining machinery. The company has established in-depth cooperation with world-renowned enterprises in the United States, Canada, Germany, Italy, Belgium, Japan, and other countries, with foreign capital customer sales accounting for more than 50%. It has also formed strategic partnerships with domestic leading high-end equipment manufacturers such as Zoomlion, XCMG, Sany, Lingsheng, CRRC, Nanjing Gear, and Zhuzhou Gear. Among its products, the market share of planetary reducer core forgings and medium-to-large lifting hook assemblies ranks first in the domestic market.