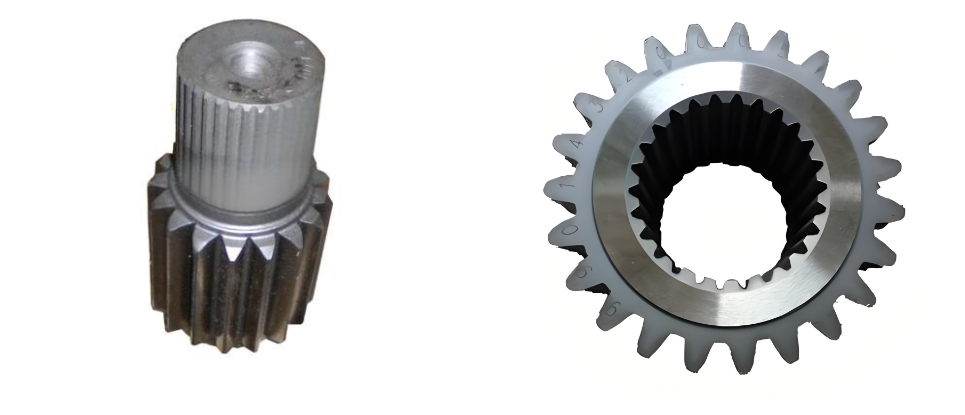

Precision Engineered Sun Gear

1.Material:17CrNiMo6-4/18CrNiMo7-6

2.Grinding outer circle: + 0.001mm

3.Tooth accuracy :5

4.Customization: We design and manufacture tailor-made products to your exact technical requirements.

5.Advantages:

Our strict process inspection ensures every product meets defect-free standards.

Streamlined one-stop processing delivers efficiency and cost savings.

From standard to custom, our wide product range solves all your needs.

6.Weight:Material usage and end-product weight will be derived from the Client’s provided drawings.

7.Craft:Forging

Product Introduction:

In a planetary tools system, the solar equipment serves as the core transmission component, centrally located inside the equipment train. It meshes with planet gears and the ring tools to allow strength transmission and pace version functions.Structural Characteristics:Typically a precision-machined steel equipment , proposing a central shaft bore.Requires excessive put on resistance and fatigue power to stand up to cyclic masses .Functional Role:Transmits torque and regulates rotational speed, broadly deployed in car transmissions, wind energy equipment, and industrial robots .Application Scenarios:New power car drivetrains .Aero-engine reducers ,Heavy equipment transmissions .

Product Advantages:

As a core factor of the planetary tools transmission system, the solar equipment has extensive complete blessings in building machinery, commonly mirrored in transmission performance, structural design, fabric innovation and practical expansion, etc. High-efficiency transmission and load-bearing capacity. Advantage Dimension: Technical symptoms of development equipment utility scenarios: High-efficiency load-bearing: Crane hoisting mechanism, torque of mining crusher elevated by means of 50%, provider existence 100,000 hours; Compact integration: excavator visiting mechanism, extent of loader gearbox halved The weight is decreased via 30%, and the cloth is lightweight. The polyurethane fabric for port equipment and wind energy gear reduces the weight by means of 50%. The transmission mode is flexible. The engineering automobile transmission machine has eight transmission ratios and adjustable steering. The smart protection predictive upkeep device reduces the failure fee by way of 40%. Translate English

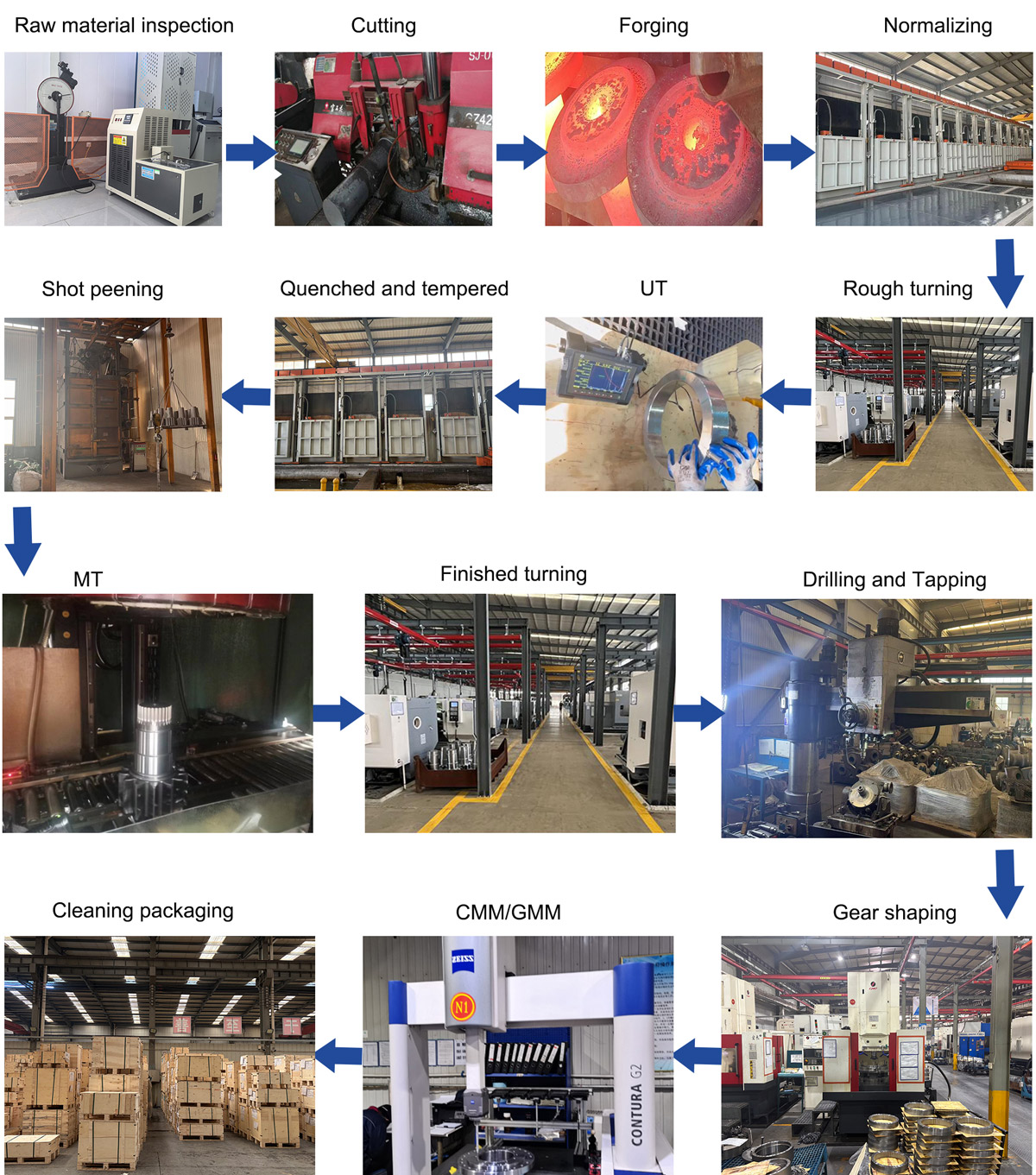

Production Process:

Raw material inspection→ Cutting→ Forging → Normalizing → Rough turning → UT → Quenched and tempered → Shot peening → MT → Finished turning → Drilling and Tapping → Shaping → CMM/GMM → Cleaning packaging

Our team will:

Clean, label, and take a appear at rust-proofing to all merchandise beforehand than shipment;

Perform a meticulous show off up inspection;

Finally pack the merchandise and keep them in our warehouse, making excessive fantastic readiness for dispatch.

Company Strength:

Over the previous 30 years of active development, the organisation has aggressively prolonged into each and every and each and every home and world markets. Its merchandise are particularly used in fields such as putting up machinery, wind electrical power generation, new electrical strength vehicles, rail transit, petrochemicals, and mining machinery. The employer has hooked up in-depth cooperation with world-renowned agencies in the United States, Canada, Germany, Italy, Belgium, Japan, and brilliant countries, with far-off places capital customer earnings accounting for large than 50%. It has in addition frequent strategic partnerships with home predominant high-end equipment producers such as Zoomlion, XCMG, Sany, Lingsheng, CRRC, Nanjing Gear, and Zhuzhou Gear. Among its products, the market share of planetary reducer core forgings and medium-to-large lifting hook assemblies ranks first in the home market.