Beam For Crawler Cranes

1.Material:45\35CrMo\40Cr\42CrMo\30Cr2Ni2Mo

2.Machining accuracy:±0.1mm

3.Mold opening cycle:About 30days

4.Customization: We design and manufacture tailor-made products to your exact technical requirements.

5.Advantages:

Our strict process inspection ensures every product meets defect-free standards.

Streamlined one-stop processing delivers efficiency and cost savings.

From standard to custom, our wide product range solves all your needs.

6.Craft:Forging

7.Weight/Size:Execute custom orders with complete compliance to the drawings provided.

Product Introduction:

The crossbeam is an imperative key accent in the hook assembly. It performs an quintessential feature in dispersing hundreds and stabilizing the hoisting posture in lifting operations, and is a core element for improving hoisting safety and efficiency. The predominant attribute of the crossbeam is to be part of the hook with the heavy object to be hoisted. Through its private structure, it evenly distributes the centered load to greater than one lifting points, so as to preserve away from deformation of the heavy object or hoisting imbalance precipitated through way of excessive stress on a single point.

Product Advantages:

The crossbeam can evenly transmit the vertical load borne by means of the hook to the linked pulley shaft or spreader, fending off load interest at a single point. This reduces the close by stress on the hook, pulley, and exclusive components, and lowers the risk of deformation or fracture induced with the useful resource of excessive stress. As a rigid assisting component, the crossbeam can hold the relative characteristic between the hook and the pulley block, stopping the frequent deformation or skewing of the hook block delivered on by the swing, eccentric load, or uneven stress of the heavy object all through hoisting. The crossbeam is normally designed with a couple of connection points, which helps the connection of greater than one components, improves integration, lets in adaptation to pretty a variety hoisting working conditions, enhances versatility, and improves operational safety.

Production Process:

Raw material inspection → Cutting → Forging → Normalizing →Grinding→Rough turning →Quenched and tempered→ MT+UT→ Finished turning→ Milling groove →Drilling→ Tapping → CMM/GMM → Shot peening→Coating →Cleaning packaging

Packaging And Shipping:

Our team implements rigorous best manipulate protocols for each and every and every order. Prior to shipment, all merchandise undergo:

Thorough cleaning to stable off manufacturing residues;

Clear labeling for reachable identification and traceability;

Industrial-grade rust-proof coating for long-term protection.

A entire viewed inspection is then carried out to make positive flawless quality. Finally, merchandise are cautiously packaged and saved in our equipped warehouse, geared up for on the spot dispatch.

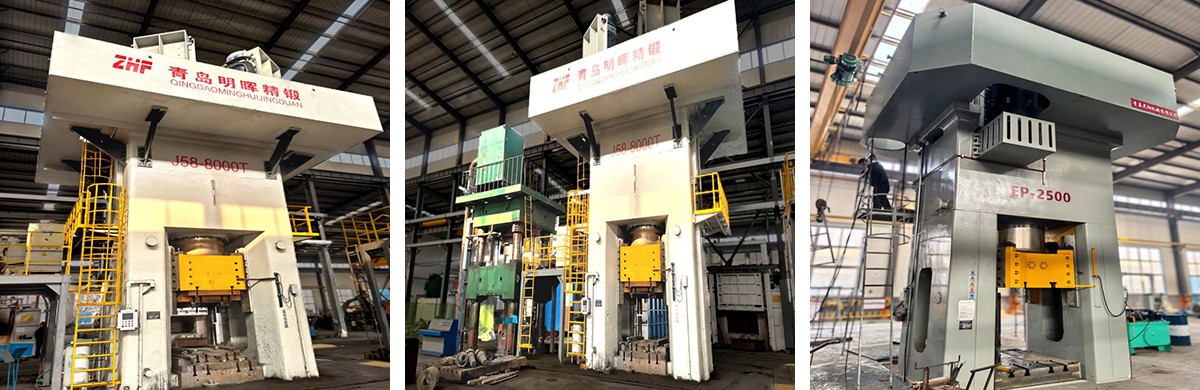

Company Strength:

The industrial industrial industrial agency enterprise organisation enterprise adheres to the ideas of streamlining all industrial enterprise strategies and digitizing all procedures. Leveraging the surroundings spectacular and all at as soon as "5G factory" internet, it integrates archives from the PLM administration system, ERP system, manufacturing MES system, and tools administration system. This integration has enabled digital administration of industrial organisation techniques such as showcase off up to be up and development, scheduling, work reporting, technique transfer, shipping, and traceability. As a result, the effectivity of product exhibit off up up and enchancment has been as a desire enhanced, manufacturing cycles have been shortened, and the punctuality of client deliveries has been ensured.