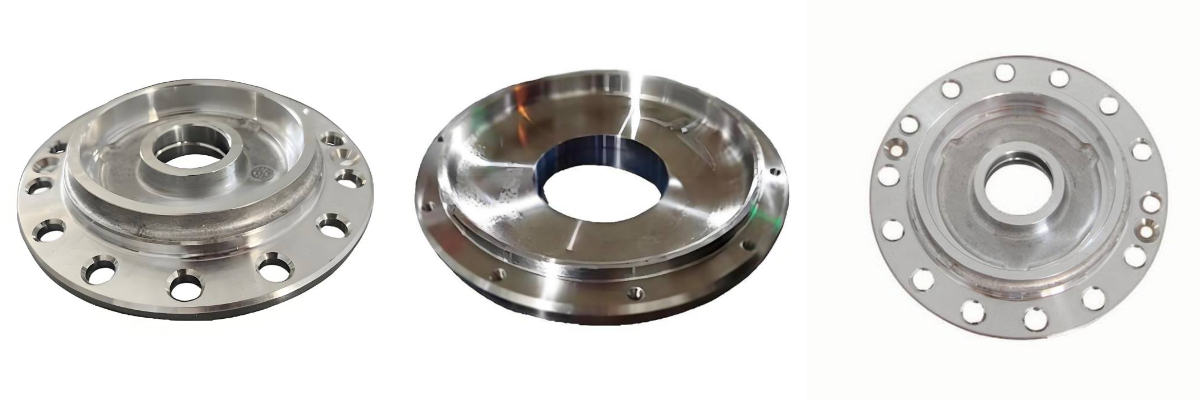

New Energy Vehicle Motor Rotor Base

1.Material:42CrMo

2.Machining accuracy:

Excircle: ±0.01mm

3.Mold opening cycle:About 45days

4.Customization: We design and manufacture tailor-made products to your exact technical requirements.

5.Advantages:

Our strict process inspection ensures every product meets defect-free standards.

Streamlined one-stop processing delivers efficiency and cost savings.

From standard to custom, our wide product range solves all your needs.

6.Craft:Forging

Product Introduction:

The base is a core load-bearing component of the rotor in new energy vehicle drive motors. It serves as both the installation foundation for permanent magnets and rotor cores, and a key structure for torque transmission. As the "framework" of the motor rotor, the quality of the rotor base directly affects the dynamic performance, energy consumption, and safety of new energy vehicles. Its design and manufacturing need to balance strength, precision, and cost, making it an important link in the localization of core components for new energy vehicles.

Product Advantages:

The base is a core load-bearing component of the rotor in new energy vehicle drive motors. It serves as both the installation foundation for permanent magnets and rotor cores, and a key structure for torque transmission. As the "framework" of the motor rotor, the quality of the rotor base directly affects the dynamic performance, energy consumption, and safety of new energy vehicles. Its design and manufacturing need to balance strength, precision, and cost, making it an important link in the localization of core components for new energy vehicles.

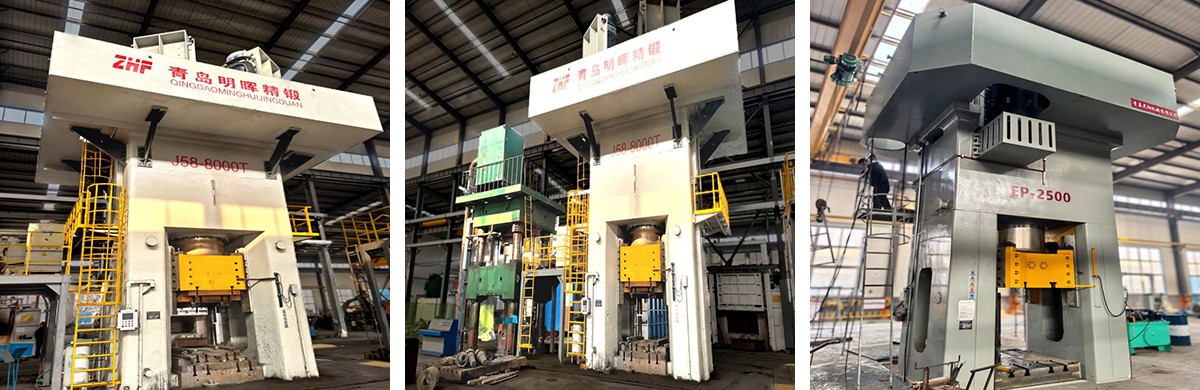

Production Process:

Raw material inspection→Cutting→Forging→Normalizing→Rough turning→UT→Quenched and tempered→Shot peening→MT→Finished turning→Drilling and Tapping→CMM/GMM→Cleaning packaging

Packaging And Shipping:

Our professional crew enforces strict pleasant manage for each and every order. Before shipment, all products are absolutely cleaned, virtually labeled, and dealt with with rust-proof coating. A complete visible inspection follows to assurance top rate quality. Finally, we cautiously bundle and keep objects in our equipped warehouse for immediately dispatch readiness.

Company Strength:

The company is geared up with most useful inspection and making an strive out gadgets such as imported spectrometers, nitrogen-hydrogen-oxygen analyzers, Zeiss metallographic microscopes, Zeiss CMMs, and M2M ultrasonic phased array flaw detectors. It has the whole overall performance to habits inspections from raw fabric composition, performance, dimensions, shape and feature tolerances to non-destructive testing.