Dumbbell Pins for Coal Mining Machinery

1.Material: 30CrMnTi

2.Machining accuracy: ±0.1mm

3.Mold opening cycle: About 45 days

4.Customization: Fabricate tailor-made products that precisely align with your technical specifications

5.Advantages:

End-to-end inspection

Complete process manufacturing capability

Full-spectrum product line

6. Weight:We will determine the material consumption and finished product weight based on the drawings supplied by the customer.

7.Craft:Forging

8.Size:Execute custom orders with 100% drawing compliance

Product Introduction:

Dumbbell pins for coal mines are greatly used in equipment such as coal mine scraper conveyors and swap machines, serving as imperative ensures for the consistent operation of these gadgets and the smooth transportation of materials. During coal mining, scraper conveyors and swap machines are required to transport coal from the mining face to particular locations. Dumbbell pins be part of each trough physique to shape a continuous and invulnerable conveying channel, making certain the smooth transportation of coal and exclusive materials.

Product Advantages:

Dumbbell pins in coal mine gear are key elements used to be a part of the core trough of the scraper conveyor. Their design and normal overall performance are essential to the stability, reliability and mining effectivity of the equipment. Dumbbell pins attribute immoderate electricity and put on resistance, high-precision wholesome and connection reliability, fast disassembly and assembly, sturdy interchangeability, the functionality to adapt to harsh working conditions, as properly as corrosion resistance and have an impact on load resistance. Reliable connection can make positive the easy operation of the scraper chain, decorate the continuity and effectivity of coal transportation, and prolong the service life of the equipment.

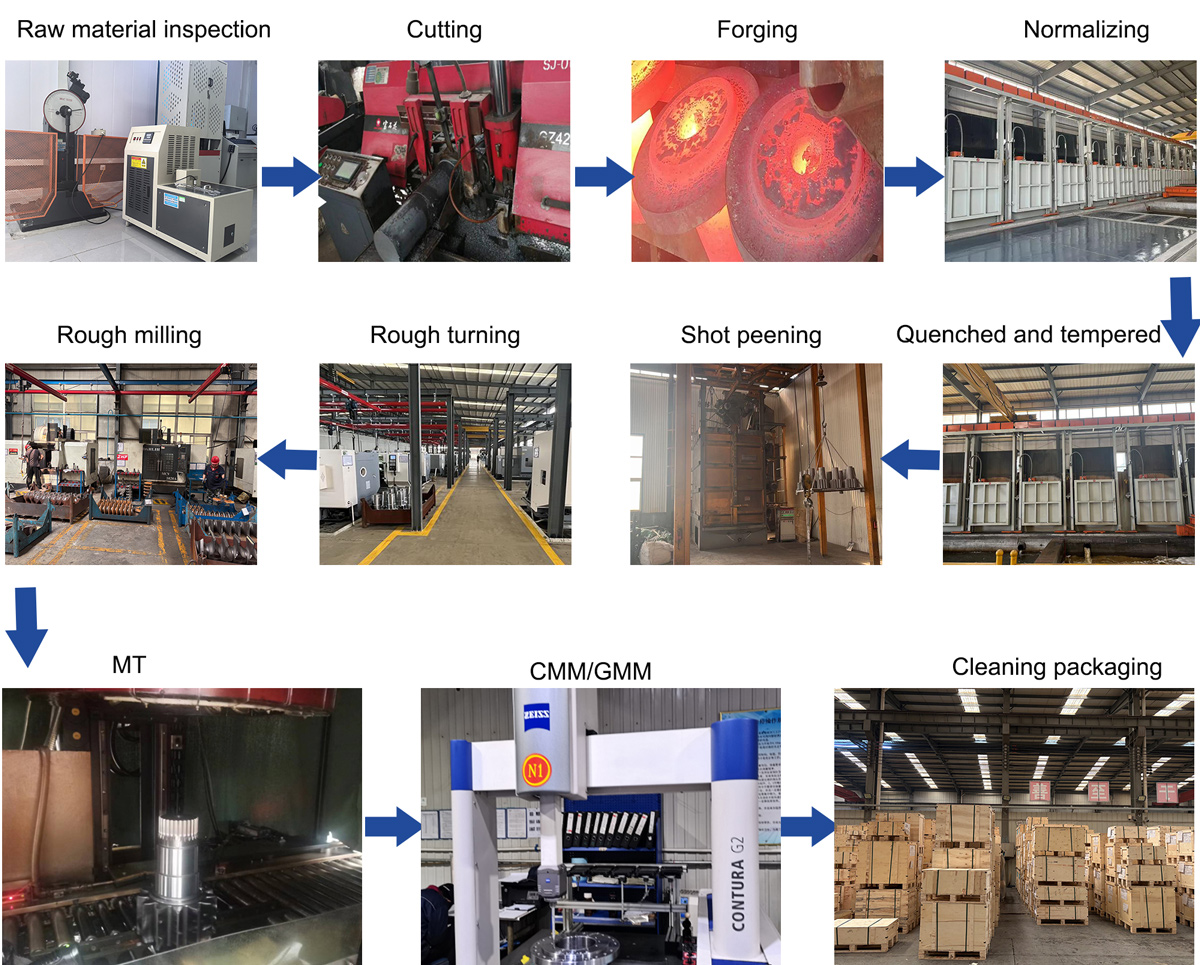

Production Process:

Raw material inspection → Cutting → Forging → Normalizing → Quenched and tempered → Shot peening → Rough turning → Rough milling → MT → CMM/GMM → Cleaning packaging

Packaging And Shipping:

Our expert team enforces strict notable manipulate for every order. Before shipment, all merchandise are completely cleaned, in truth labeled, and treated with rust-proof coating. A entire seen inspection follows to assurance pinnacle charge quality. Finally, we cautiously package deal deal and preserve objects in our organized warehouse for without delay dispatch readiness.

Company Strength:

The organization is equipped with finest inspection and making an attempt out devices such as imported spectrometers, nitrogen-hydrogen-oxygen analyzers, Zeiss metallographic microscopes, Zeiss CMMs, and M2M ultrasonic phased array flaw detectors. It has the entire performance to habits inspections from raw cloth composition, performance, dimensions, form and position tolerances to non-destructive testing.