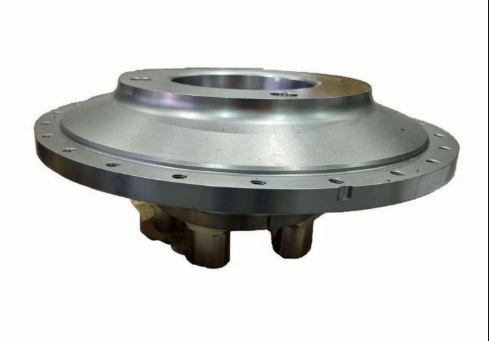

Finished Product Support Shaft

1.Material:42CrMo/40Cr

2.Machining accuracy:±0.01mm

3.Mold opening cycle:About 45 days

4.Customization: We design and manufacture tailor-made products to your exact technical requirements.

5.Advantages:

Our strict process inspection ensures every product meets defect-free standards.

Streamlined one-stop processing delivers efficiency and cost savings.

From standard to custom, our wide product range solves all your needs.

6.Weight:Material usage and end-product weight will be derived from the Client’s provided drawings.

7.Craft:Forging

Product Introduction:

Support shafts are crucial foundational elements in mechanical systems, mainly used to information rotating bodies, transmit loads, keep motion accuracy, and limit frictional wear. Their core characteristic lies in imparting constant mechanical useful resource for rotating equipment, making positive surroundings pleasant electricity transmission and reliable structural operation.As cylindrical mechanical parts, information shafts are usually built-in with bearings, seals, and lubrication constructions to form a total assist unit. Though interestingly simple, information shafts serve as the "backbone" of industrial equipment—ranging from micro-shafts in devices (e.g., Ø2.3mm) to ship propulsion shafts spanning lots of meters. Their layout consistently revolves spherical three core demands: load-bearing, stress transmission, and durability.Looking ahead, with traits in clever manufacturing and new materials, help shafts will in a similar fashion evolve closer to lightweight integration, clever perception, and inexperienced regeneration, constantly underpinning industrial innovation.

Product Advantages:

Support shafts, as core components in mechanical systems, show great benefits during structural design, material performance, purposeful diversity, and economic efficiency. Based on technical small print and utility cases, their core strengths are systematically analyzed as follows:1. High Load Capacity & Stability:Rigid Support: Through optimized geometric constructions (e.g., stepped designs, bolstered ribs), assist shafts stand up to immoderate radial/axial lots (e.g., heavy-duty strong steel shafts exceeding 20 kN), making positive constant operation under have an effect on or vibration .Dynamic Balancing: In high-speed conditions (e.g., wind turbine shafts at 1,500 rpm), dynamic balancing calibration controls vibration with precision up to ±0.02 mm, stopping accuracy loss due to imbalance .2. Compact & Integrated Design Space Efficiency: Integrated assist shafts (e.g., CSB's aluminum shafts) obtain lengths up to 3,000 mm, minimizing auxiliary aid structures. Ideal for space-constrained functions like robotic hands and compact equipment .System Simplification: Dual-function facts shafts serve as structural pillars, inserting off more helps and decreasing set up complexity and prices .3. Future Innovation DirectionsWith Industry 4 advancements, aid shafts will evolve toward:Composite Materials: Carbon fiber-reinforced shafts minimize weight by using ability of 30% even as bettering fatigue resistance .Intelligent Perception: Embedded sensors (e.g., stress gauges) allow real-time deformation monitoring .Remanufacturing Repair: Laser cladding technological expertise cuts replacement expenses with the aid of 30%, aligning with spherical financial machine needs .These upgrades will constantly energy high-end equipment improvement .

Production Process:

Raw material inspection→ Cutting→ Forging → Normalizing → Rough turning → UT → Quenched and tempered → Shot peening → MT → Finished turning → Drilling and Tapping → Shaping → CMM/GMM → Cleaning packaging

Our team will:

Clean, label, and take a exhibit up at rust-proofing to all merchandise in the preceding than shipment;

Perform a meticulous show off up inspection;

Finally pack the merchandise and hold them in our warehouse, making splendid readiness for dispatch.

Company Strength:

Over the preceding 30 years of lively development, the organisation has aggressively prolonged into every and each and every and each domestic and world markets. Its merchandise are pretty used in fields such as placing up machinery, wind electrical power generation, new electrical electrical energy vehicles, rail transit, petrochemicals, and mining machinery. The agency has hooked up in-depth cooperation with world-renowned companies in the United States, Canada, Germany, Italy, Belgium, Japan, and excellent countries, with far-off locations capital buyer salary accounting for accelerated than 50%. It has in addition everyday strategic partnerships with domestic predominant high-end tools producers such as Zoomlion, XCMG, Sany, Lingsheng, CRRC, Nanjing Gear, and Zhuzhou Gear. Among its products, the market share of planetary reducer core forgings and medium-to-large lifting hook assemblies ranks first in the domestic market.