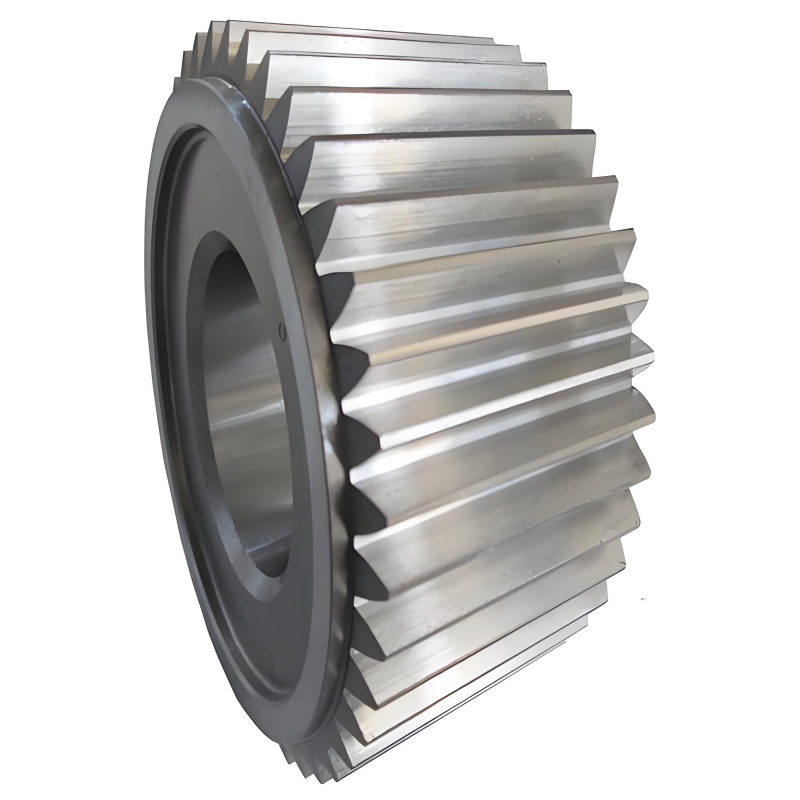

Premium Planetary Gears

1.Material:17CrNiMo6-4/18CrNiMo7-6

2.Machining accuracy:

External cylindrical grinding: ±0.001mm

Tooth accuracy: Grade 5

3.Mold opening cycle:About 30 days

4.Customization: Made-to-order services are available.

5.Advantages:

Full-process inspection

Full-process processing capability

Full-range products

6.Weight/Size: Produce according to the drawings.

7.Craft:Forging

Product Introduction:

Planetary gears are a essential issue of the planetary gear mechanism in wind turbine speed-increasing gearboxes. Their manufacturing device is specifically problematic and often consists of approaches such as steelmaking, forging, post-forging normalizing and tempering, difficult machining, carburizing and quenching, and finishing. Each manner has strict requirements for processing accuracy and first-class to make sure the dimensional accuracy, enamel profile accuracy, and ground fine of the planetary gears, thereby guaranteeing their reliable operation beneath high-speed and heavy-load conditions.

Product Advantages:

Planetary gears as a key issue of the planetary gear train, the format and manufacturing advantages at as soon as have an impact on the transmission efficiency, reliability, and provider life of speed-increasing gearboxes. With a couple of teeth collaboratively bearing loads, they feature immoderate residence utilization, carrying out a balance between lightweight and immoderate strength. Their profile exchange science improves meshing accuracy, making positive convenient transmission with low vibration and noise. The enamel surfaces undergo intensive shot peening remedy to form a compressive stress layer, thereby extending fatigue resistance and provider life.

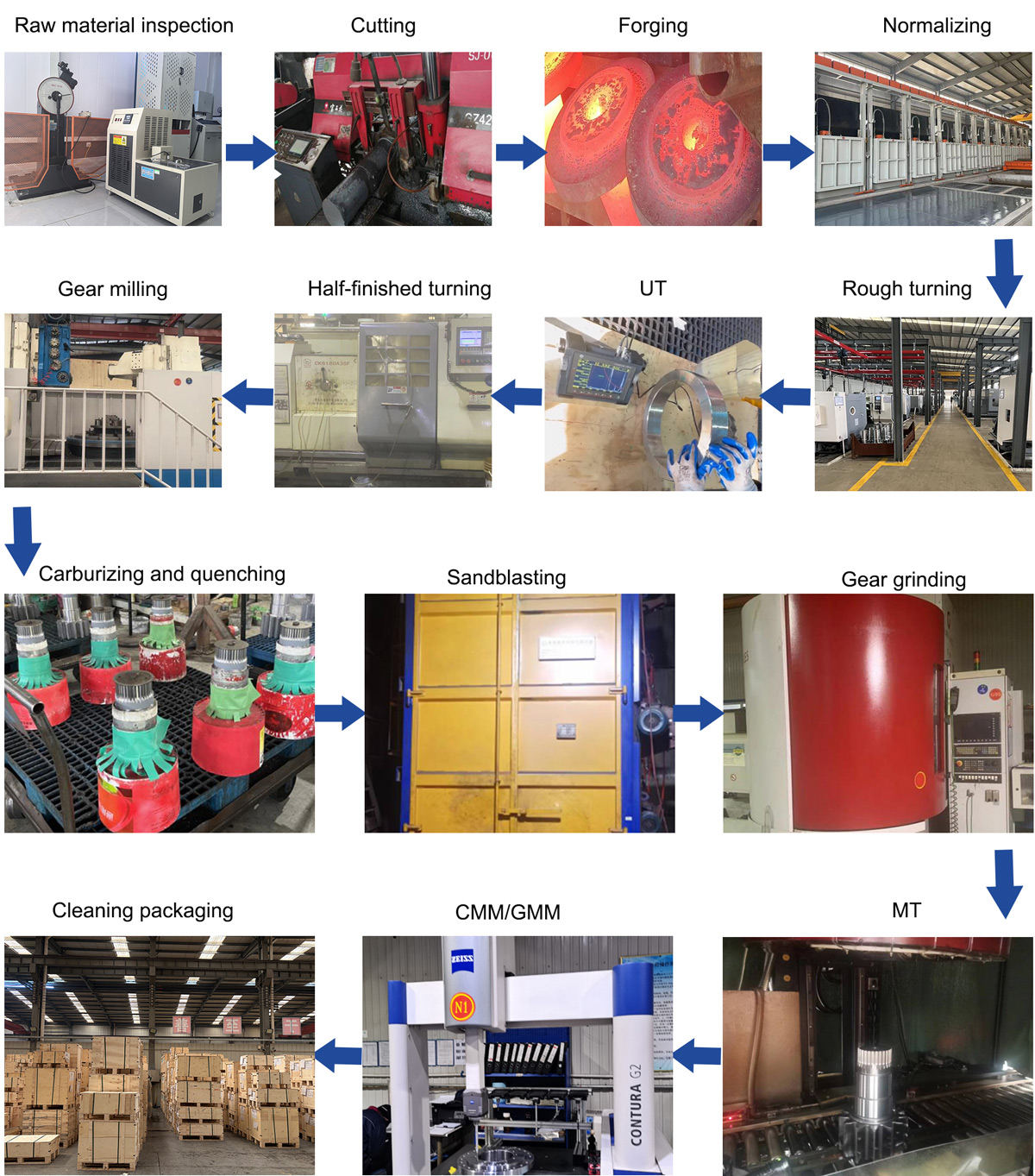

Production Process:

Raw material inspection → Cutting → Forging → Normalizing → Rough turning → UT → Half-finished turning → Gear milling → Carburizing and quenching → Sandblasting → Gear grinding → MT → CMM/GMM → Cleaning packaging

Packaging And Shipping:

Before shipment, the merchandise will go by means of a method that consists of cleaning, labeling, rust-proofing, appear inspection, and in the cease packing and warehousing.

Company Strength:

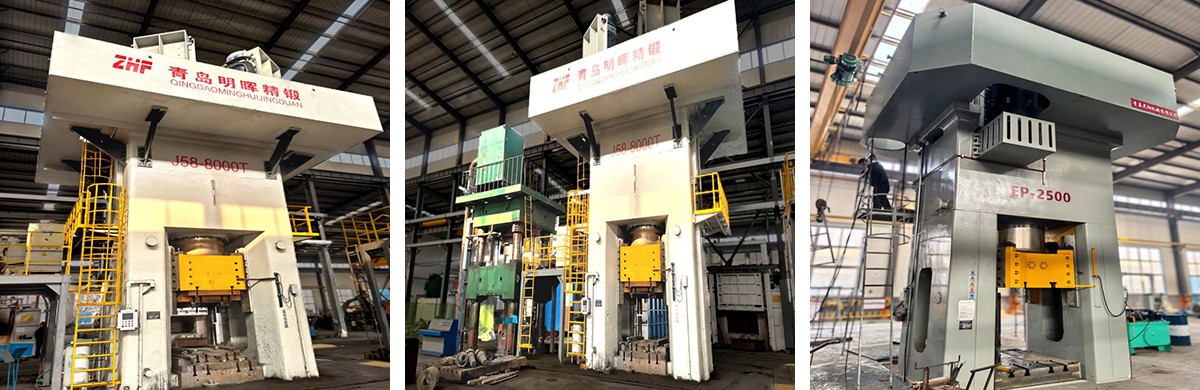

The organization is geared up with optimum inspection and making an attempt out devices such as imported spectrometers, nitrogen-hydrogen-oxygen analyzers, Zeiss metallographic microscopes, Zeiss CMMs, and M2M ultrasonic phased array flaw detectors. It has the entire performance to habits inspections from uncooked material composition, performance, dimensions, structure and function tolerances to non-destructive testing.