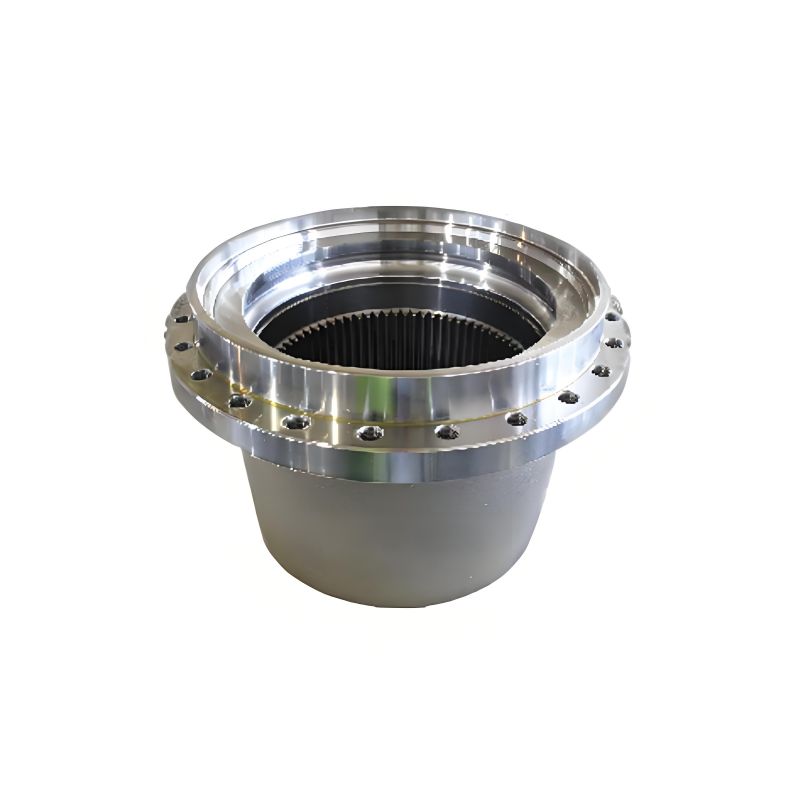

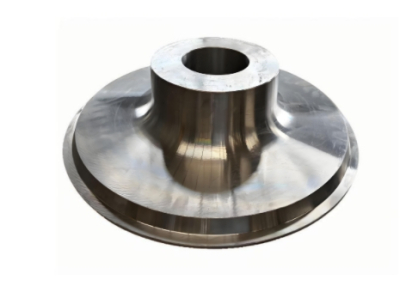

Custom-made Gear Ring

1.Material:42CrMo/40Cr

2.Machining accuracy:±0.01mm

3.Mold opening cycle:About 45 days

4.Craft:Forging

5.Advantages:

Our strict process inspection ensures every product meets defect-free standards.

Streamlined one-stop processing delivers efficiency and cost savings.

From standard to custom, our wide product range solves all your needs.

6.Weight:Material usage and end-product weight will be derived from the Client’s provided drawings.

Product Introduction:

A core element in mechanical transmission systems, the internal gear ring belongs to the category of gear components. Its defining structural feature is its internal tooth configuration—this design allows it to mesh with external gears, facilitating the transfer of both power and motion. Acting as a "precision link" in power transmission processes, the internal gear ring’s design and layout have a direct bearing on the operational efficiency and service lifespan of the equipment it is installed in. From powder metallurgy gear rings utilized in automotive transmissions, to carburized steel gear rings applied in wind turbine gearboxes, and nylon coupling internal gear rings used in robotic joints, these components deliver value through three critical attributes: precise meshing performance, dependable force transmission, and robust resistance to varying environmental conditions.

Product Advantages:

The gear ring, a vital part of mechanical transmission systems, distinguishes itself with high transmission efficiency, a compact structure, strong load-bearing ability, and impact resistance. It has an annular internal tooth design that meshes with external gears (such as planetary gears and sun gears), achieving a transmission efficiency of more than 95% while reducing power loss to the greatest extent. Its space-efficient structure makes it especially ideal for applications where space is limited, enabling it to be smoothly integrated into complex transmission systems.

Production Process:

Raw material inspection→ Cutting→ Forging → Normalizing → Rough turning → UT → Quenched and tempered → Shot peening → MT → Finished turning → Drilling and Tapping → Shaping → CMM/GMM → Cleaning packaging

Packaging and Shipping

Our team will follow the procedures outlined below:

First, we will clean all products, affix suitable labels to them, and apply anti-rust treatment prior to shipment.

Next, we will perform a comprehensive inspection of each individual product to verify that they comply with the required standards.

Lastly, we will package the qualified products appropriately and store them in our warehouse—ensuring they are fully ready for subsequent delivery.

Company Strength:

Over its three decades of vigorous development, the enterprise has taken a proactive approach to expanding into both domestic and global markets. Its products are widely used in industries such as construction machinery, wind power generation, new energy vehicles, rail transit, petrochemicals, and mining machinery.

The company has built in-depth cooperative relationships with world-famous enterprises from the United States, Canada, Germany, Italy, Belgium, Japan, and beyond—with overseas sales contributing to over 50% of its total revenue. Additionally, it has established stable strategic partnerships with leading domestic high-end equipment manufacturers, including Zoomlion, XCMG, Sany, Lingsheng, CRRC, Nanjing Gear, and Zhuzhou Gear.

Within its product range, the core forgings for planetary reducers and medium-to-large hook assemblies rank first in terms of market share in the domestic market.