Parts Of Excavator Boom

1.Material:35#(ASTM:1035 EN:C35E4 DIN:CK35),20MnMo,20#

2.Machining accuracy:±0.5mm

3.Customization: We design and manufacture tailor-made products to your exact technical requirements.

4.Advantages:

Our strict process inspection ensures every product meets defect-free standards.

Streamlined one-stop processing delivers efficiency and cost savings.

From standard to custom, our wide product range solves all your needs.

5.Weight:Material usage and end-product weight will be derived from the Client’s provided drawings.

6.Craft:Forging

7.Size:Execute custom orders with complete compliance to the drawings provided.

Product Introduction:

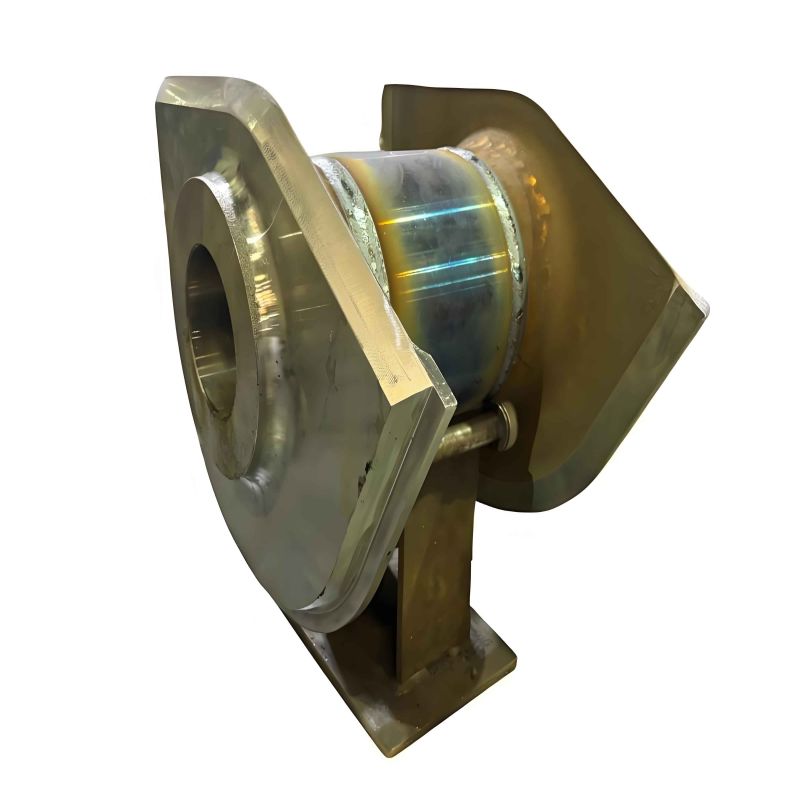

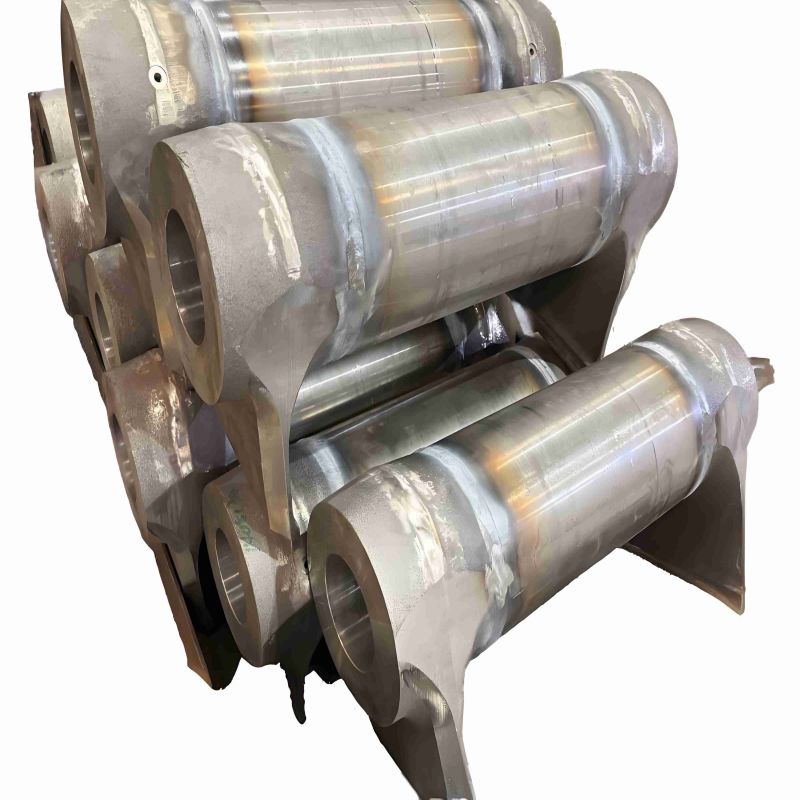

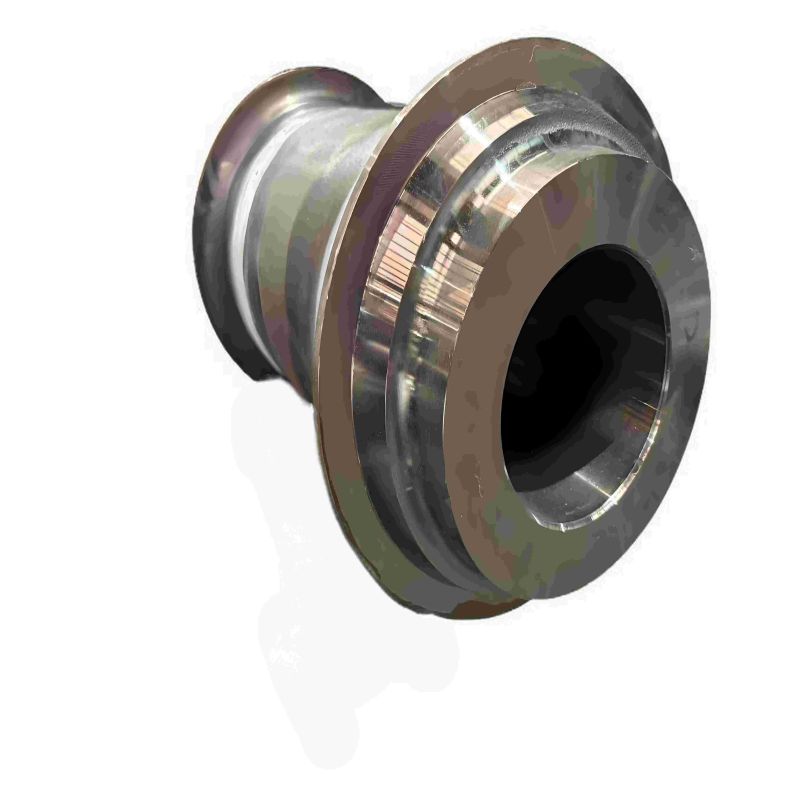

The mid-support assembly of an excavator's boom serves as a critical structural element within the excavator's working mechanism (specifically the boom). Its primary role is to boost the boom's structural stability, distribute the load stress generated during operational processes, and offer connection pivots for associated components—all to guarantee the boom operates reliably under high-intensity working conditions, such as excavation tasks and heavy object lifting. Typically, this mid-support assembly consists of several key parts: a support base, shaft sleeves, and connecting pins. These components are commonly manufactured from forged steel or high-strength alloy steel to ensure durability. In certain design configurations, reinforcing ribs or bushings are also integrated into the assembly. These additional elements help minimize wear and tear on the structure while enhancing the overall assembly precision.

Product Advantages:

As a pivotal forged component, the design and performance advantages of an excavator boom’s middle support assembly exert a direct influence on the excavator’s operational efficiency, safety, and service life. The middle support assembly leverages forging technology, which ensures the components boast precise dimensions and consistent mechanical properties. This technological choice enables the assembly to effectively disperse stress concentrations in the boom’s middle section, thereby lowering the risk of localized wear or damage. Functioning as the "support hub" for the boom’s mid-section, its structural design—such as a support base equipped with reinforcing ribs and high-precision shaft sleeves—enhances the boom’s overall rigidity. This reduces wobbling or deformation during operation, guarantees more accurate movements of the bucket and stick, and ultimately boosts excavation efficiency.

Production Process:

Forgings + Pipe Fittings Assembly → Welding → Non-Destructive Testing → Cleaning & Packaging → Shipment

Packaging and Shipping

Our dedicated team will implement a rigorous, multi-step quality assurance and preparation process for all merchandise prior to shipment, ensuring each item meets our strict standards for protection, traceability, and readiness:

First, we will conduct a thorough cleaning of every product to remove any dust, debris, or residual materials accumulated during manufacturing or storage—this step is critical to preserving the product’s surface integrity and preventing contamination. Next, each cleaned item will receive clear, detailed labeling that includes key information such as product model number , batch code, specifications, and handling instructions; this labeling ensures seamless identification, inventory tracking, and compliance with logistics requirements throughout the shipping process. Following labeling, we will apply a professional rust-proofing treatment (such as anti-rust oil coating, VCI film wrapping, or corrosion-resistant packaging) to all metal components or susceptible parts, forming a protective barrier against moisture, oxidation, and environmental damage during transit and storage.

After completing the pre-shipment preparation, our team will perform a meticulous, item-by-item inspection. This inspection covers not only the completeness of cleaning, labeling, and rust-proofing but also a thorough check of product dimensions, structural integrity, functional performance (where applicable), and adherence to order specifications—any discrepancies or defects identified will be addressed immediately to avoid issues downstream.

Finally, once the inspection is passed, each merchandise item will be carefully packed using high-quality, shock-absorbing packaging materials (such as custom-fitted foam inserts, corrugated cartons, or wooden crates for heavy-duty products) to cushion against impacts and vibrations during transportation. The packed products will then be organized and stored in our climate-controlled, well-ventilated warehouse, where they are kept in designated areas to prevent damage from stacking or mishandling. This systematic approach ensures that all merchandise is in perfectly optimal condition, making fully accurate and prompt readiness for dispatch the moment shipping instructions are received.

Company Strength:

Over the past 30 years of robust development, the company has proactively expanded its reach into both domestic and global markets. Its product portfolio finds extensive application across key industries, including construction machinery, wind power generation, new energy vehicles, rail transit, petrochemicals, and mining machinery—catering to the diverse operational needs of each sector.

Globally, the company has established in-depth collaborative partnerships with world-renowned enterprises hailing from countries such as the United States, Canada, Germany, Italy, Belgium, and Japan. This international footprint is reflected in its overseas sales performance, where revenue from foreign markets accounts for more than 50% of its total sales volume. Domestically, it has also forged strategic alliances with leading high-end equipment manufacturers, including industry giants like Zoomlion, XCMG, Sany, Lingsheng, CRRC, Nanjing Gear, and Zhuzhou Gear—strengthening its position as a trusted supplier in the domestic high-end equipment chain.

In terms of product competitiveness, the company stands out in key segments: its core forgings for planetary reducers and medium-to-large lifting hook assemblies have achieved a dominant market position, securing the first rank in market share within the domestic market. This leadership not only underscores the quality and reliability of its products but also solidifies its role as a pivotal player in supporting the development of both domestic and global heavy industry and equipment manufacturing sectors.