The differences between forging and casting of the excavator boom and arm shaft seat.

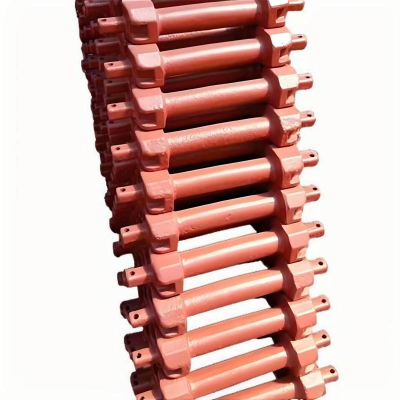

The boom shaft seat of an excavator is a key load-bearing component that connects the boom and the cylinder. Its manufacturing process (forging or casting) directly affects the performance and lifespan of the equipment.

1. Material properties and structural strength

1) Forged shaft seat:

Grain structure: Through high-temperature and high-pressure plastic deformation (such as upsetting and drawing), the metal grains are refined along the direction of force (can be refined to less than 5μm), forming continuous flow lines, which enhance tensile strength (up to over 850MPa) and yield strength (>700MPa).

Defect control: Eliminate casting defects such as porosity and shrinkage cavities, with internal density >99.9%, fatigue life increases by 3 to 5 times, suitable for withstanding the impact loads of excavation.

Case: A forged boom shaft seat has been in continuous operation for 1000 hours without deformation or cracks, significantly reducing the failure rate.

2) Cast shaft seat:

Structural limitations: During the cooling and solidification of molten metal, it is prone to the formation of pores and inclusions, with coarse grains and segregation, resulting in relatively low strength (about 70% of forged parts) and insufficient toughness.

Risk points: Under alternating loads, cracks are likely to initiate at defect sites, and long-term use may lead to a risk of fracture.

2. Production Technology and Cost Efficiency

1) Forging Process:

Process: Requires a 10,000-ton press for die forging, combined with free forging for pre-forming (e.g., the boom pin seat needs to be upset first to improve the structure), with high precision requirements for the die (dimensional tolerance ±0.05mm).

Cost: High unit cost (die cost accounts for 30% to 50%), suitable for medium and small batch production; but material utilization rate > 90%, with less waste.

2) Casting Process:

Adaptability: Can form complex geometric structures in one piece (such as irregular oil passage holes). Sand casting/metal casting is suitable for large-scale production, reducing unit cost by 40%.

Defect Cost: Subsequent X-ray inspection and heat treatment are required to repair defects, and the overall cost may exceed forging.

3. Design Freedom and Lightweighting

1) Casting Advantage: Can integrate complex features such as reinforcing ribs and weight-reducing cavities, reducing weight by 15% to 20% (such as aluminum alloy cast bearing seats).

2) Forging Limitation: Shape is restricted by the mold, usually requiring secondary processing (such as milling oil holes), but wall thickness can be optimized to thinner (such as 4mm), and local reinforcement can be achieved through topology design.

4. Application Scenario Comparison

Indicators Forging Bearing Seat Casting Bearing Seat

Load Capacity Heavy-duty (>50-ton excavators) Medium-light-duty (10,000 hours 5,000 to 8,000 hours.

Maintenance Cost Low (failure rate Medium-high (frequent defect repair)

5. Economic Decision-Making Suggestions

1) Choose Forging: When the equipment needs long-term high-intensity operation (such as mining excavators), or when extremely high safety redundancy is required (such as deep foundation pit engineering).

2) Choose Casting: For cost-sensitive projects (such as small agricultural machinery), or scenarios with extremely complex shapes .

6. Process Innovation Trends

1) Composite Manufacturing: 3D printed casting cores + local forging reinforcement, balancing complexity and strength (such as Sany Heavy Industry's patented solution).

2) Intelligent Monitoring: Implanting sensors in the forging process to real-time control temperature/pressure, reducing internal stress .

The choice of process for excavator boom bearing seats is essentially a "performance-cost-life" triangle game. Forging bearing seats: Pay for ultimate reliability and long life, suitable for heavy-duty and high-value equipment; Casting bearing seats: Prioritize economy and have cost-effectiveness in light-duty scenarios.