Industrial sprockets for industrial transmission and conveying: The core pillar of efficient industrial operation

Industrial sprockets for industrial transmission and conveying: The core pillar of efficient industrial operation

In industrial Settings - from manufacturing plants to heavy processing plants - power transmission and material conveying are the lifelines that ensure production efficiency. Among the key components that maintain the operation of these systems, industrial sprockets are undoubtedly indispensable. It is precisely designed to fit with the chain, seamlessly transmitting rotational power to ensure the stable material transmission of the conveyor and uninterrupted power transmission. This is very important in industries such as petrochemicals. The harsh environment in the petrochemical industry places extremely high demands on the performance of each component. As a key petrochemical accessory, industrial sprockets directly affect the safety, efficiency and service life of equipment in petrochemical production. The following text will delve into the significance of industrial sprockets, their role in the petrochemical industry, selection methods, and best maintenance practices.

1. Industrial sprockets: Core components of transmission and conveying systems

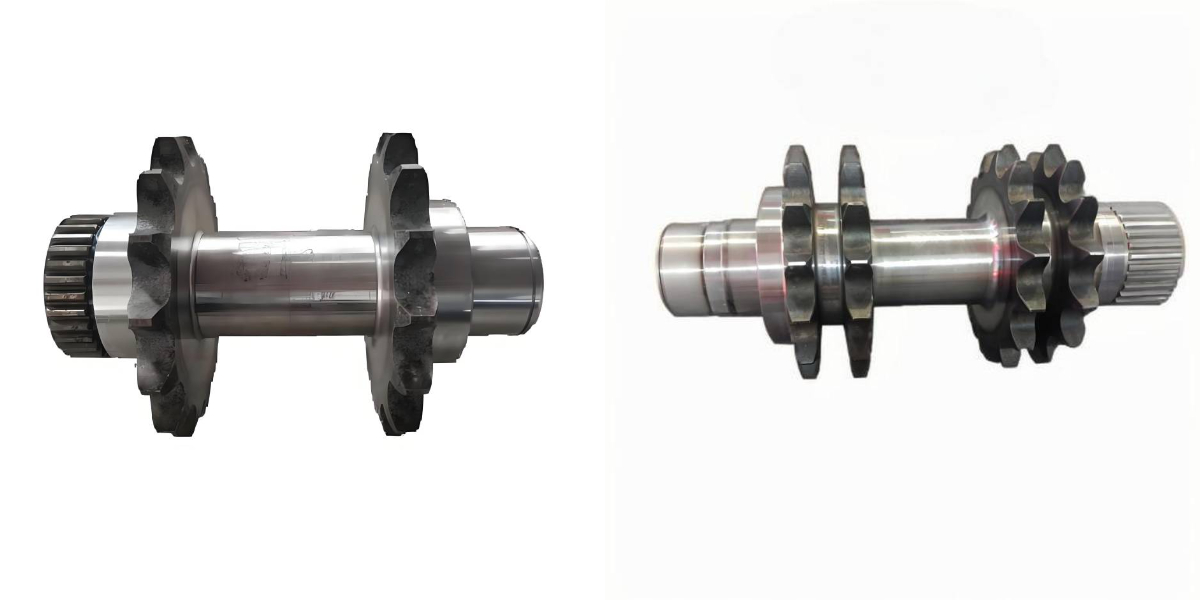

Essentially, an industrial sprocket is a toothed wheel that works in coordination with a chain to achieve power transmission or material transportation. Sprockets rely on chains to establish flexible and durable connections.

Industrial sprockets are irreplaceable. Its design will be customized according to specific load, rotational speed and environmental requirements. For instance, petrochemical accessories used in oil refineries (such as sprockets) need to have the properties of resisting hydrocarbon corrosion and withstands high temperatures, while sprockets in mining conveying equipment pay more attention to wear resistance. If high-quality industrial sprockets are lacking, conveyors are prone to frequent jamming, the power transmission efficiency will drop significantly, and the entire production line may even come to a standstill.

2. Why are industrial sprockets the key to the petrochemical industry

The petrochemical industry is one of the industries with the most stringent requirements for industrial equipment. From crude oil extraction to its refining into plastics, fuels or chemicals, each link involves heavy machinery, corrosive substances and must comply with strict safety standards.

Precision processing technology

Smooth tooth surface and uniform tooth pitch are the keys to the performance of sprockets. Teeth with insufficient processing accuracy are prone to cause chain slippage, uneven power transmission or premature wear. Industrial sprockets with small pitch tolerances (such as ±0.05 millimeters) should be selected to ensure perfect meshing with the chain. This is particularly important in petrochemical conveying equipment. Even a slight alignment deviation can cause equipment failure.

Load capacity

Petrochemical conveying equipment and machinery need to bear heavy loads - sometimes reaching several tons per hour. The rated load of industrial sprockets must match the actual working conditions. When making a purchase, it is necessary to check the parameters of "maximum torque" and "maximum chain tension" of the sprocket to ensure that they can meet the requirements of petrochemical applications.

3.Compatibility with chains

The following are the core maintenance methods:

Regular inspection

Inspect the industrial sprocket weekly or monthly, with a focus on:

Tooth wear: If the teeth become round, cracked or missing, it indicates that the sprocket needs to be replaced.

Corrosion or damage: In petrochemical environments, it is necessary to check whether the sprocket has rusted, pitted or had its coating peel off due to chemical substances.

Lubrication and maintenance

Replace in a timely manner

Cleaning and maintenancet.

4.Conclusion

Industrial sprockets are by no means ordinary gear discs - they are the core pillars of power transmission and conveying systems in many industries, especially in the petrochemical industry. As a key petrochemical accessory, industrial sprockets ensure production continuity, withstand harsh environments, and facilitate safety compliance. Petrochemical enterprises can minimize downtime, reduce costs and ensure efficient production operation by choosing the right industrial sprockets (featuring durable materials, precise processing, load adaptability and other characteristics) and following regular maintenance norms.

Whether you are upgrading the conveying system or replacing worn parts, investing in high-quality industrial sprockets is a reliable investment for the long-term development of petrochemical enterprises.