Dumbbell Link Pin Parts

1.Material: 30CrMnTi

2.Machining accuracy: ±0.1mm

3.Mold opening cycle: About 45 days

4.Customization: Fabricate tailor-made products that precisely align with your technical specifications

5.Advantages:

End-to-end inspection

Complete process manufacturing capability

Full-spectrum product line

6. Weight:We will determine the material consumption and finished product weight based on the drawings supplied by the customer.

7.Craft:Forging

Product Introduction:

Dumbbell pins are essential components widely used in key coal mining equipment such as scraper conveyors and reversed loader machines. They play a critical role in ensuring the continuous, stable operation of this equipment and the smooth transportation of mined materials. In the coal mining process, scraper conveyors and reversed loaders are tasked with conveying coal from the working face to designated transfer or storage locations. Dumbbell pins serve as the core connecting parts that link the individual trough sections of these conveyors, forming a continuous, tightly sealed conveying channel. This robust connection ensures unimpeded transit of coal and other materials, preventing disruptions caused by loose or misaligned troughs during heavy-duty, high-intensity mining operations.

Product Advantages:

Dumbbell pins are key connecting components for the main trough sections of scraper conveyors in coal mining equipment. Their structural design and overall performance are pivotal to the operational stability, reliability, and mining efficiency of the entire conveyor system. These pins boast a host of superior characteristics: exceptional strength and wear resistance to withstand constant impact and friction; high-precision dimensional accuracy and reliable connectivity to ensure tight, stable jointing of trough sections; easy disassembly and assembly paired with strong interchangeability for quick maintenance and replacement underground; as well as excellent adaptability to harsh working conditions, along with strong corrosion and impact load resistance to cope with the humid, dusty, and high-vibration environment of coal mines. A secure, dependable connection achieved by these dumbbell pins ensures the smooth operation of the scraper chain, enhances the continuity and efficiency of coal transportation, and ultimately extends the service life of the entire scraper conveyor equipment.

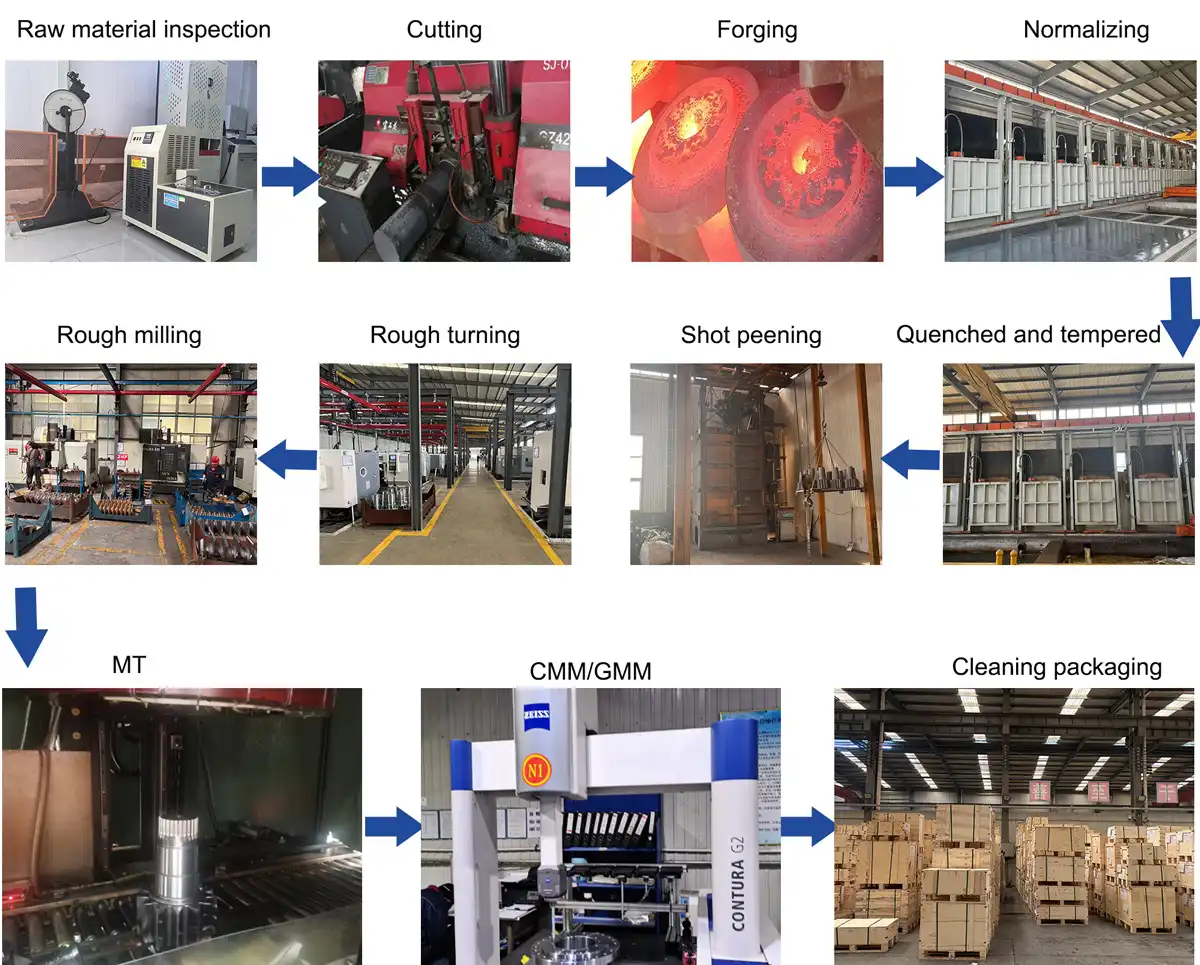

Production Process:

Raw material inspection → Cutting → Forging → Normalizing → Quenched and tempered → Shot peening → Rough turning → Rough milling → MT → CMM/GMM → Cleaning packaging

Packaging And Shipping:

Our dedicated specialist team implements a stringent, order-specific quality control protocol for every single consignment, leaving no room for oversight. Prior to shipment, all products undergo a three-step pre-dispatch preparation process to ensure optimal condition: first, each unit is thoroughly cleaned using industrial-grade methods to remove machining residues, surface contaminants, and dust; next, standardized, scannable labels with clear product information—including model number, batch code, and technical specifications—are affixed to every item; finally, targeted rust-proofing treatments are applied, such as corrosion-inhibiting coatings for metal components and vacuum-sealed packaging for precision parts, to safeguard against oxidation during transit and storage. Following this preparation, a comprehensive and meticulous inspection is carried out by our certified quality inspectors. This check covers dimensional accuracy, surface finish, rust-proofing effectiveness, and label consistency, all verified against strict industry standards and customer requirements to guarantee top-tier quality. Only after passing all inspections are the products carefully packaged using shock-absorbent foam, moisture-resistant liners, and reinforced cartons, tailored to each item’s size and fragility. These packaged goods are then systematically stored in our well-organized warehouse, sorted by order number for easy retrieval, ensuring they are fully prepared for prompt and seamless dispatch as soon as shipping instructions are confirmed.

Company Strength:

The enterprise is equipped with a comprehensive suite of top-tier inspection and testing equipment, including imported spectrometers, nitrogen-hydrogen-oxygen analyzers, Zeiss metallographic microscopes, Zeiss coordinate measuring machines (CMMs), and M2M ultrasonic phased array flaw detectors. This state-of-the-art hardware portfolio endows the company with full-cycle, all-dimensional testing capabilities that cover every critical quality checkpoint throughout the production process. It enables precise and comprehensive inspections ranging from the qualitative and quantitative analysis of raw material chemical compositions, the rigorous evaluation of core material performance metrics (such as hardness, tensile strength, impact toughness, and fatigue resistance), the ultra-precise measurement of product dimensions, geometric tolerances, and positional accuracy, to the NDT of internal and surface structures. These advanced testing tools ensure that even micro-level defects, structural irregularities, or performance deviations can be detected early, laying a solid foundation for consistently delivering high-quality products that meet stringent industry standards and customer requirements.