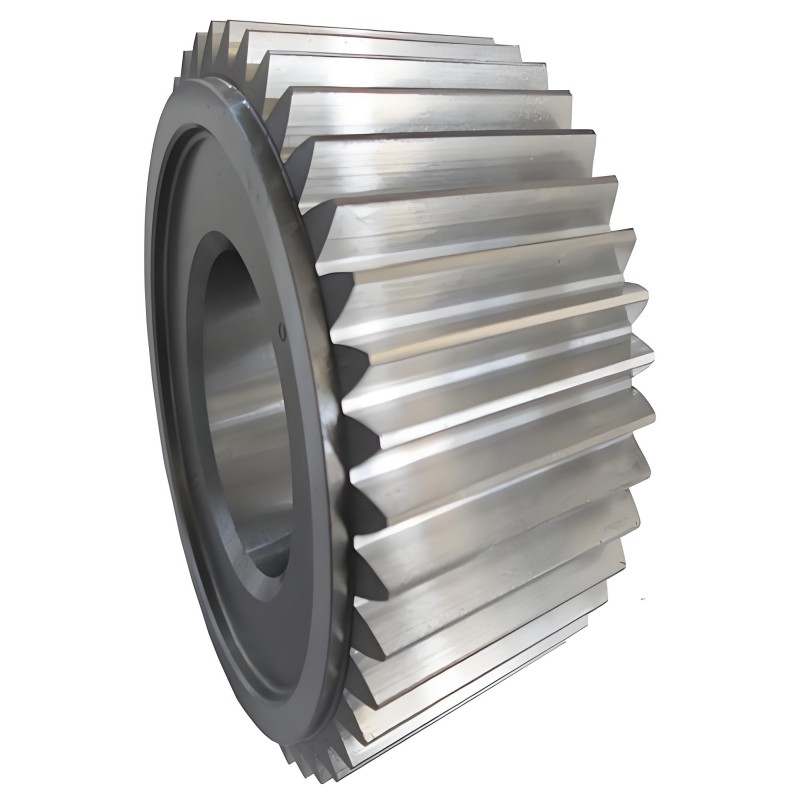

Planetary Gear Forging Parts

1.Material:17CrNiMo6-4/18CrNiMo7-6

2.Machining accuracy:

External cylindrical grinding: ±0.001mm

Tooth accuracy: Grade 5

3.Mold opening cycle:About 30 days

4.Customization: Made-to-order services are available.

5.Advantages:

Full-process inspection

Full-process processing capability

Full-range products

6.Weight/Size: Produce according to the drawings.

7.Craft:Forging

Product Introduction:

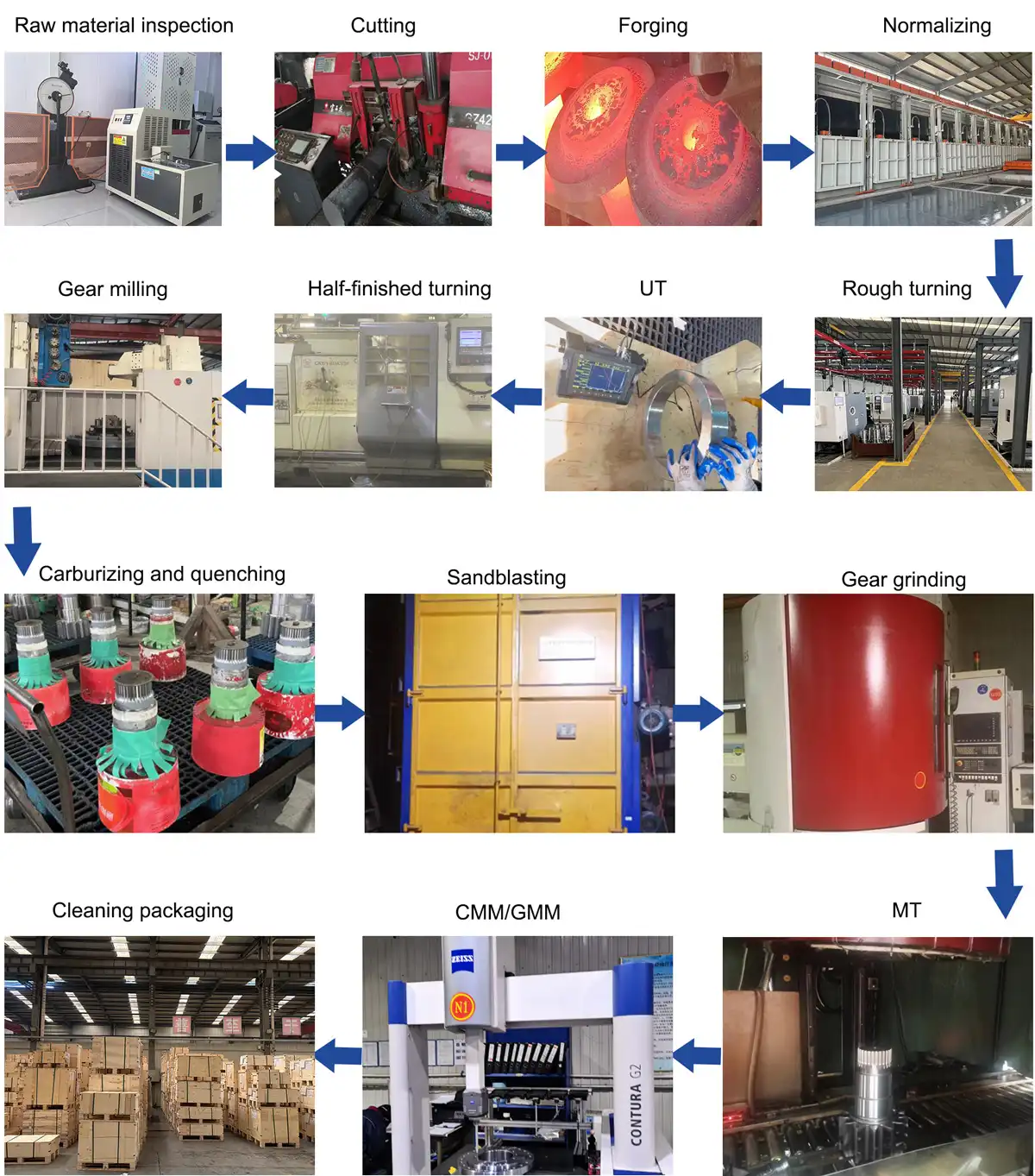

Planetary gears are vital core parts of the planetary gear train in wind turbine speed-increasing gearboxes. Their key job is to efficiently convert the turbine’s low rotor speed into the high speed required for electricity generation. The manufacturing process of these gears is complex and requires high precision, following a set sequence of steps. First, high-quality alloy steel is produced to ensure consistent material performance. Then comes hot forging, which boosts the gears’ structural strength and durability. After forging, normalizing and tempering treatments are applied to reduce internal stresses and make the material easier to machine. Next, rough machining processes like turning and milling shape the gears into their basic form. Then carburizing and quenching create a hard, wear-resistant surface while keeping the core tough. Finally, precision finishing such as grinding and honing ensures ultra-precise dimensions. Every step demands strict quality control. From the uniformity of the steel composition to machining tolerances and surface smoothness, all details are closely monitored. This is essential to ensure the gears can perform stably and reliably under the harsh operating conditions of wind turbines—high rotation speeds, heavy dynamic loads, and constant cyclic stress—thus supporting the long-term efficiency and durability of the entire wind power system.

Product Advantages:

As a pivotal element of the planetary gear train, planetary gears have a direct, make-or-break impact on the transmission efficiency, operational reliability, and service life of speed-increasing gearboxes. Their overall performance hinges entirely on two critical factors: innovative structural design and premium manufacturing quality. Designed with a multi-tooth load-sharing mechanism, these gears are exceptionally space-efficient, featuring a compact layout that maximizes power density. This design achieves an ideal balance between lightweight construction and robust mechanical strength, allowing seamless integration into the confined space of gearbox enclosures without sacrificing load-bearing capacity or long-term durability. To ensure superior meshing precision, advanced tooth profile optimization technologies are employed—including refined involute curve design and micro-topography adjustments. These enhancements minimize gear backlash, ensure even force distribution across tooth surfaces, and enable smooth, low-vibration, low-noise power transmission even when operating under dynamic load conditions. In addition, the gear tooth surfaces undergo a rigorous shot peening process. High-velocity metal pellets are projected onto the gear surface, creating a residual compressive stress layer that effectively offsets the tensile stresses generated during operation. This treatment significantly boosts the gears’ fatigue resistance, reduces the risk of crack initiation and spread, and ultimately extends their service life—a critical advantage for maintaining the long-term performance of speed-increasing gearboxes in high-demand working environments.

Production Process:

Raw material inspection → Cutting → Forging → Normalizing → Rough turning → UT → Half-finished turning → Gear milling → Carburizing and quenching → Sandblasting → Gear grinding → MT → CMM/GMM → Cleaning packaging

Packaging And Shipping:

Prior to shipment, all products must go through a fully integrated pre-shipment preparation and quality control process, designed to ensure each unit meets strict standards before leaving the facility. First, every item is subjected to a deep cleaning process—either ultrasonic cleaning for precision components or high-pressure washing for bulkier parts. This step effectively removes surface contaminants, machining residues, and any lingering impurities, guaranteeing a clean, blemish-free finish that satisfies both functional requirements and aesthetic expectations. Next, standardized, regulation-compliant labels are applied to each product, clearly stating key information including batch codes, technical specifications, operating instructions, and safety precautions. These labels facilitate easy identification, streamline inventory management, and ensure proper end-use by customers. Based on the specific material properties of each product, targeted anti-corrosion measures are then implemented. Metal components are treated with rust-inhibiting coatings, sealed in vacuum packaging, or coated with industrial-grade anti-rust oil; sensitive electronic or mechanical parts are wrapped in moisture-proof films to prevent oxidation and rust during storage and long-distance transit. Immediately after these preparatory steps, professional quality inspectors carry out comprehensive checks—combining visual assessments with basic dimensional verification—to spot any potential defects such as scratches, dents, deformations, or functional inconsistencies that could compromise performance. Only products that pass these rigorous inspections proceed to the final packaging stage, where they are secured with protective materials like shock-absorbent foam inserts, reinforced corrugated cartons, and moisture-resistant liners to guard against damage from rough handling, vibration, or environmental exposure. Finally, the fully prepared products are stored in a well-organized warehouse, sorted by order for quick and efficient retrieval. They remain in this designated area, ready for immediate dispatch as soon as shipping schedules are confirmed. This seamless, end-to-end process—spanning cleaning, labeling, rust-proofing, inspection, packaging, and warehousing—ensures every product is delivered in optimal condition, laying the groundwork for safe transportation and reliable performance for the end user.

Company Strength:

The company is equipped with a comprehensive array of state-of-the-art inspection and testing instruments, including imported spectrometers, nitrogen-hydrogen-oxygen analyzers, Zeiss metallographic microscopes, Zeiss coordinate measuring machines (CMMs), and M2M ultrasonic phased array flaw detectors. This world-class hardware setup equips the company with full-cycle, all-dimensional testing capabilities that cover every critical quality checkpoint throughout the production process. It enables accurate analysis of the chemical composition of raw materials, strict evaluation of key material performance metrics such as hardness and tensile strength, precise measurement of dimensional accuracy and geometric tolerances, and in-depth assessment of structural integrity. What’s more, these advanced tools support high-precision non-destructive testing (NDT), a pivotal function that identifies tiny internal flaws, micro-cracks, and structural anomalies without causing any damage to the materials or finished products. This robust, multi-tiered quality testing system ensures rigorous validation at every stage—from incoming raw material inspection to final product approval. It not only guarantees that all products deliver consistent reliability and superior quality but also highlights the company’s steadfast dedication to adhering to the most stringent standards of precision, technological excellence, and operational integrity across its entire business operations.