Shaft Sleeve Crane Chassis Parts Hollow Coupling Sleeve: Forging-enabled Crane Parts Core Shaft Sleeve

Shaft Sleeve Crane Chassis Parts Hollow Coupling Sleeve: Forging-enabled Crane Parts Core Shaft Sleeve

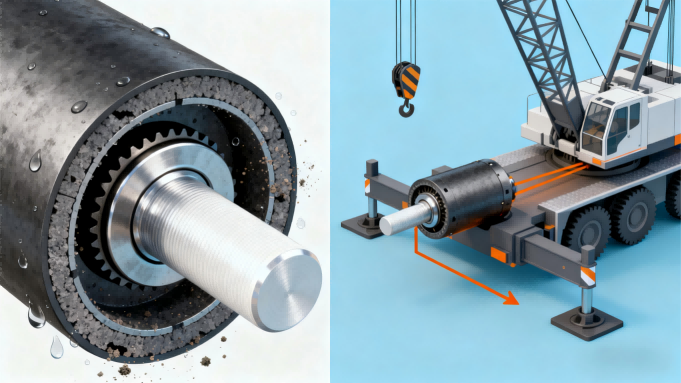

In the complex mechanical system of cranes, the reliability of crane parts directly determines the operational safety and service life of the entire machine. Among them, shaft sleeve, as a key transmission and protection component, is widely used in core parts such as crane chassis, slewing mechanism, and winch system. And hollow coupling sleeve, as an important subtype of shaft sleeve, undertakes the core mission of precise force transmission and shock absorption and vibration reduction. The forging process, with its ultimate optimization of material properties, has become the core technical support for the manufacturing of high-end crane bushings. The three together form the "invisible cornerstone" for the efficient and stable operation of cranes. This article will comprehensively analyze the technical characteristics of bushings and hollow connecting sleeves, the enabling value of forging processes, application scenarios, and key points for selection and maintenance, to help gain a deeper understanding of their core role in the crane parts system.

I. Core Definition: Shaft Sleeve - The "protective and transmission center" of crane parts

1.The essence and core function of bushings

Shaft sleeve is a cylindrical mechanical part that is sleeved on the surface of the rotating shaft of a crane. It belongs to the core crane parts and mainly plays three core functions:

Protective function: Isolate the rotating shaft from the external environment, prevent erosion by dust, impurities and moisture, avoid wear and rust of the rotating shaft, and extend the service life of the rotating shaft.

Friction reduction and wear resistance: By means of its own material properties or lubrication design, it reduces the friction coefficient between the rotating shaft and the mating parts (such as bearings, housing), reduces power loss, and improves transmission efficiency.

Positioning and buffering: Precisely position the installation of the rotating shaft, limit radial displacement, and simultaneously absorb vibration and shock during operation to ensure the smooth operation of the transmission system.

2. The exclusive value of Hollow Coupling Sleeve

The hollow coupling sleeve is a special application form of the shaft sleeve in the crane chassis transmission system, and its core is suitable for the connection scenarios of shafts to shafts and shafts to gears.

Precise force transmission: With a hollow structure and high-precision dimensional design, stable torque transmission is achieved, ensuring efficient transmission of the crane chassis power from the motor and gearbox to the wheels or slewing mechanism.

Compensation deviation: Through its own slight elastic deformation, it compensates for the coaxiality deviation during the installation process, reduces stress concentration, and protects the rotating shaft and gears at the connection part.

Convenient assembly: The hollow structure is easy to disassemble, assemble and maintain, meeting the installation requirements in the narrow space of the crane chassis and improving operation and maintenance efficiency.

Ii. Bushings in Crane Parts: Types and Applicable Scenarios

The complexity of crane working conditions (heavy load, vibration, outdoor environment) determines that the bushings need to be custom-designed according to the requirements of different parts. Common types and application scenarios are as follows:

1.The types of bushings classified by material

Metal bushings: The mainstream type, with materials mostly being 45# steel, 42CrMo, tin bronze, etc., processed through forging techniques, suitable for heavy-load and high-speed transmission scenarios (such as crane hoist bushings, chassis drive bushings).

Non-metallic bushings: such as nylon bushings and engineering plastic bushings, feature lightweight and self-lubricating properties, and are suitable for low-speed, light-load, and oil-free lubrication scenarios (such as crane handrail mechanisms and small rotary joints).

Composite bushing: Combining a metal substrate with a non-metallic wear-resistant layer, it takes into account both strength and anti-friction properties, and is suitable for complex scenarios with medium to heavy loads and medium rotational speeds (such as the bushing of crane luffing mechanisms).

2. Core application scenarios: Covering key systems of cranes

Crane chassis: The hollow connecting sleeve, as a core component, is adapted to the connection between the chassis drive shaft and the gearbox, withstanding the instantaneous impact load during start-up and braking, ensuring driving stability.

Slewing mechanism: The bushing is sleeved on the slewing bearing shaft, reducing the frictional resistance during the slewing process, ensuring the precise positioning of the crane boom, and is suitable for frequent slewing operation scenarios such as ports and construction sites.

Winch system: The bushing is installed on the shaft of the winch drum, isolating the drum from the bearing, resisting the lateral pressure brought by the winding of the steel wire rope, and ensuring the transmission reliability during heavy-load lifting.

Luffing mechanism: The bushing is adapted to the connection part between the luffing cylinder and the boom, absorbing the vibration during the luffing process, preventing component loosening, and enhancing the smoothness of the boom's lifting and lowering.

Iii. Forging process: properties of Shaft Sleeve "Forger"

As the core Crane Parts, the bushing needs to withstand the heavy load, vibration and alternating load during the operation of the crane. Forging process is the key guarantee for achieving high performance and has irreplaceable advantages compared with processes such as casting and cutting processing:

1. Enhance the mechanical properties of the material to adapt to heavy-load impact

During the forging process, the metal billet undergoes plastic deformation under high temperature and high pressure, and the grains are refined and densified, completely eliminating defects such as porosity, porosity and segregation in the raw materials. Forged bushings have significantly enhanced tensile strength, yield strength and impact toughness. For instance, the tensile strength of 42CrMo alloy steel forged bushings can reach over 800MPa, which can easily withstand the instantaneous impact during heavy load lifting and emergency braking of cranes, preventing deformation or breakage of the bushings.

2. Ensure structural integrity and enhance operational stability

The crane bushings (especially the hollow connecting sleeves) should have an integrated structure to avoid weak links. The forging process adopts integral forging forming without welding seams, which structurally eliminates the safety hazards caused by welding defects (such as cracks and incomplete penetration). The stress distribution of the integrally forged bushing is uniform, and it is less likely to develop fatigue cracks under long-term alternating loads, which is suitable for the high-strength requirements of 24-hour continuous operation of cranes.

3. Optimize dimensional accuracy and surface quality to adapt to precision transmission

Modern cranes have increasingly higher requirements for transmission accuracy, and the dimensional tolerance of bushings needs to be controlled at the micrometer level. The forging process is precisely formed through custom molds, and only a small amount of fine processing is required subsequently to meet the dimensional requirements. This not only ensures the precise fit between the shaft sleeve and the rotating shaft as well as the mating parts, reducing the vibration and noise caused by the mating clearance, but also lowers material waste and processing costs. Meanwhile, the surface roughness of the forged bushing is low, and it can achieve a good lubrication effect without additional grinding.

4. Adapt to complex structural designs and meet customized demands

The shaft sleeve structures of different types of cranes (crawler cranes, truck cranes, and port cranes) vary significantly. Hollow connecting sleeves, in particular, need to be designed with dedicated hollow hole diameters and connection interfaces based on the shaft diameter and torque requirements. Forging processes can be customized through molds to achieve integrated forming of complex structures. Whether it is stepped bushings, hollow bushings with keyways or irregular-shaped bushings, they can precisely meet the design requirements and adapt to the customized production needs of crane parts.

Iv. Manufacturing and Quality Control of high-quality Crane Bushings: Full-process control from forging to finished products

The production of high-end crane bushings involves multiple strict procedures, each of which directly affects the final performance. The core process is as follows:

1. Raw material screening: Laying the foundation for quality

High-strength alloy structural steels (such as 45# steel, 42CrMo, 35CrNiMo) should be given priority as billets. The raw materials need to pass composition testing and mechanical property tests to ensure the absence of harmful substances and internal defects, providing high-quality base materials for the forging process.

2. Forging process implementation: Precisely control parameters

Blanking: Cut the billet according to the size of the bushing to ensure that the weight and volume of the billet are precisely matched.

Heating: Heat the billet to the forging temperature of 800-1200℃ to ensure that the metal plasticity reaches the best state.

Forging forming: By using die forging or free forging processes, the billet is pressed into the preset shape through pressure equipment (the hollow connecting sleeve needs to be synchronously formed into a hollow structure).

Cooling: Slow cooling or isothermal cooling should be adopted to avoid cracks and internal stress caused by rapid cooling.

3. Subsequent processing: Optimize precision and performance

Rough machining: Remove the excess allowance from the forging blank and initially form the key dimensions such as the inner and outer diameters and length of the bushing.

Heat treatment: The comprehensive mechanical properties of the bushing are enhanced through quenching and tempering (quenching + high-temperature tempering). The surface can be treated with nitriding, quenching and other processes to increase hardness and wear resistance.

Precision machining: Precision machining is carried out using CNC lathes, grinders and other equipment to ensure that dimensional tolerances and shape and position tolerances meet the design standards. For hollow connection sleeves, special attention should be paid to ensuring the accuracy of the hollow hole diameter and the connection interface.

4. Quality Inspection: Strict control at every level

Dimensional inspection: Using equipment such as a three-coordinate measuring machine and a laser rangefinder, 100% inspection is carried out on key dimensions such as the inner and outer diameters, length, wall thickness, and coaxiality of the shaft sleeve.

Non-destructive testing: Internal cracks, inclusions and other defects that may occur during the forging process are identified through UT and MT.

Performance testing: Sampling is conducted for hardness testing, tensile strength testing, and wear resistance testing to ensure that the product meets the strict standards for crane parts.

V. Selection and Maintenance: Focusing on forging quality to ensure the efficient operation of cranes

1. Key points for selecting bushings

Give priority to forged products: Confirm whether the bushing adopts an integral forging process, review the forging process report and material certificate, and avoid using cast or welded parts (with insufficient strength and toughness, prone to failure under heavy load).

Match the working condition requirements: According to the type of crane (such as truck crane, crawler crane), the working scene (heavy load/light load, high speed/low speed), and the installation part (chassis/hoist/slewing), select the corresponding material and structure of the bushing. For example, 42CrMo forged bushing is preferred for heavy load scenarios.

Check the dimensional accuracy: Ensure that the inner and outer diameters, lengths, and fit tolerances of the bushing are precisely matched with the rotating shaft and installation position. For hollow connecting sleeves, it is particularly important to confirm the hollow hole diameter and connection method (key connection, interference fit, etc.).

2. Key matters for daily maintenance

Regularly inspect the condition of the bushing: Focus on checking whether there is wear, scratches or cracks on the surface of the forged bushing, especially at the areas where force is concentrated (such as the interfaces at both ends and keyways). Replace it immediately if any defects are found.

Ensure lubrication effect: Regularly add suitable lubricating oil to avoid dry friction causing wear between the shaft sleeve and the rotating shaft. The lubricating oil should be selected based on the ambient temperature and load conditions.

Cleaning and protection: Timely clean the dust, oil stains and impurities on the surface of the shaft sleeve to prevent corrosive substances from damaging the surface of the shaft sleeve and extend its service life.

Regular replacement: Based on the operation intensity and running time of the crane, determine the replacement cycle of the bushing. Generally, under heavy-load working conditions, it is recommended to replace it once every 1-2 years to avoid failure caused by fatigue aging.

Vi. Industry Development Trends: Upgrading of Forging Technology and Iteration of Bushing Performance

With the development of cranes towards larger size, intelligence and lighter weight, the Shaft Sleeve, which is the core Crane Parts, also shows three major development trends, and the upgrading of forging technology is the core driving force:

1. Balancing lightweight and high strength

By combining new forging materials (such as high-strength aluminum alloys and composite materials) with precision forging processes, the weight is further reduced while ensuring the strength of the bushing, lowering the overall energy consumption of the crane and meeting the lightweight requirements of large cranes.

2. Intelligent integrated design

Sensors (temperature, vibration and wear sensors) are integrated into the forged bushings to monitor the operating status and wear degree of the bushings in real time. The data is transmitted to the intelligent operation and maintenance platform of the crane through the Internet of Things to achieve fault early warning and predictive maintenance, reducing downtime losses.

3. Digital upgrade of forging processes

Introduce digital twins, industrial robots and intelligent detection equipment to achieve digital control of the entire process of bushing forging. From the heating temperature of the billet, forging pressure to cooling rate and finishing accuracy, the entire process is monitored in real time and data is traced to enhance the consistency and stability of forging quality, meeting the large-scale and standardized production requirements of crane parts.

Summary

Shaft Sleeve, as the core crane parts, is a key component of the crane transmission and protection system, and the hollow connecting sleeve is the core hub for force transmission of the crane chassis. The forging process endows the bushing with the core capability to adapt to the complex working conditions of cranes by enhancing material properties, ensuring structural integrity, and improving precision stability. The deep integration of the three is an important guarantee for the safe, efficient and long-term operation of cranes.

From heavy-duty cranes in ports to truck cranes on construction sites, from traditional mechanical cranes to intelligent automated equipment, forging-enabled bushings have always played a crucial role behind the scenes. In the future, with the digital upgrade of forging technology, the application of new materials and the implementation of intelligent design, bushings will further achieve performance iteration, injecting strong impetus into the high-quality development of the crane industry and continuously safeguarding the safety and efficiency of global industrial production and engineering construction.