What Does The Output Shaft Do In A Gearbox? The Output Shaft Of The Transmission: The Core Of Power Transmission Empowered By Forging

What does the output shaft do in a gearbox? The output shaft of the transmission: The core of power transmission empowered by forging

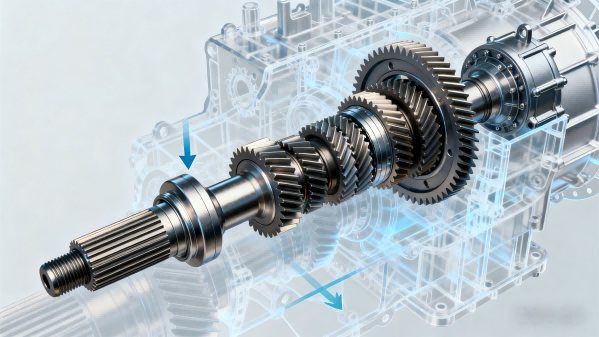

In the mechanical transmission system, the gearbox is the "power center" for regulating rotational speed and transmitting torque, while the output shaft, as the core actuating component of the gearbox, directly determines the efficiency and stability of power transmission. The manufacturing of high-end output shafts cannot do without the support of forging technology. By optimizing material properties and strengthening structural strength, the output shafts can meet the heavy-load and high-frequency transmission requirements under complex working conditions. This article will comprehensively answer the question of "What is the function of the output shaft in the transmission?", deeply analyze the core functions of the output shaft, the enabling value of forging technology, technical characteristics and application scenarios, and help to fully understand its key position in the transmission system.

I. Core Answer: The core role of the output shaft in the gearbox

Output shaft is the "ultimate executor" of power transmission in the gearbox. Its core function is to precisely transmit the power that has undergone speed change and torque change inside the gearbox to the terminal actuator (such as wheels, working devices). Specifically, it can be decomposed into three core functions:

The "transmission hub" of torque and rotational speed

The core mission of a transmission is to convert speed and torque (decelerate and increase torque or increase speed and reduce torque) through gear meshing according to the working conditions. One end of the output shaft is rigidly connected to the driven gear inside the gearbox, receiving the power converted by the gear set. Then, through the flange, spline and other structures at the other end, the power is transmitted to the drive shaft, differential or directly drive the working components, completing the closed loop of "power input - conversion - output". For instance, in a car transmission, the output shaft transmits the adjusted power to the wheels, enabling the vehicle to accelerate, decelerate or travel at a constant speed. In industrial gearboxes, the output shaft drives the operation of equipment such as conveyor belts and mixers.

2. The "Precise Locator" for Power Transmission

The output shaft is connected to the gearbox housing through bearings. Its shaft shoulder, splines and other structures must ensure precise fit with gears and connecting parts, limit the axial displacement of gears, and ensure uniform gear meshing clearance. This precise positioning not only reduces the impact and noise during the transmission process, but also prevents excessive wear of gears due to misalignment, ensuring the smoothness and accuracy of power transmission and extending the overall service life of the gearbox.

3. "Load-bearing Core" for Complex Working Conditions

During operation, the output shaft needs to bear both radial loads (lateral forces generated by gear meshing) and axial loads (thrust in power transmission) simultaneously. Especially under conditions such as heavy load, frequent start-stop, and rapid acceleration, the loads will present instantaneous peaks. Therefore, the output shaft must have sufficient strength, toughness and fatigue resistance to withstand the impact of alternating loads and avoid deformation or fracture. This is also the key reason why forging technology has become the core manufacturing method for high-end output shafts.

Ii. Technical Characteristics of output shaft: Adapted to the strict requirements of gearbox

The application scenarios of gearboxes cover multiple fields such as automobiles, construction machinery, wind power, and machine tools. The performance requirements for output shafts vary significantly in different scenarios, but the core technical characteristics are highly unified:

High strength and high toughness coexist

It needs to withstand torque of several hundred to several thousand Newton-meters and resist instantaneous impact loads at the same time. Therefore, high-strength alloy structural steels such as 42CrMo and 35CrNiMo are mostly selected for materials, and the material properties must be optimized through forging processes.

2. High-precision dimensional and positional tolerances

The dimensional tolerances of key parts such as the shaft diameter, spline tooth profile, and shaft shoulder end face should be controlled at the micrometer level. The shape and position tolerances such as coaxiality and circular runout must strictly meet the standards to ensure precise fit with gears and bearings and reduce transmission losses.

3. Excellent wear resistance and fatigue resistance

The splines, mating end faces and other parts of the output shaft will have long-term friction with other components and need to withstand long-term alternating loads. Therefore, the surface needs to undergo heat treatment processes such as quenching and tempering, nitriding and quenching to enhance surface hardness and wear resistance. The core part is refined by forging to improve grain size and enhance fatigue resistance.

4. Strong structural adaptability

Depending on the type of transmission (manual transmission, automatic transmission, planetary gearbox, etc.), the structural design of the output shaft varies. For instance, the output shaft of an automotive transmission often features splined grooves, while that of an industrial gearbox is usually designed as a flange structure. However, the core load-bearing and transmission functions remain consistent, and both need to achieve structural integrity through forging processes.

Iii. Forging process: The core guarantee for the high performance of output shaft

As the core load-bearing component of the gearbox, the requirements for the mechanical properties of the material of the output shaft far exceed those of ordinary mechanical parts. The forging process, through the plastic deformation treatment of the metal billet, has become a key means to improve the performance of the output shaft and has irreplaceable advantages compared with casting and cutting processing:

1. Strengthen the material structure and enhance mechanical properties

During the forging process, the metal billet undergoes plastic flow under high temperature and high pressure, and the grains are refined and densified, completely eliminating internal defects such as porosity, porosity and segregation in the raw materials. The output shaft after forging can increase its tensile strength, yield strength and impact toughness by more than 30%. For instance, after die forging, the tensile strength of 42CrMo alloy steel can reach over 800MPa, which can easily withstand the instantaneous impact under heavy load conditions and prevent the shaft body from deforming or breaking.

2. Ensure structural integrity and reduce weak links

The splines, shaft shoulders, flanges and other parts of the output shaft are stress concentration areas. The integral forging process can be adopted to achieve integrated forming without welding seams, eliminating the safety hazards caused by welding defects (such as cracks and incomplete penetration) structurally. The output shaft of integral forging has a uniform stress distribution and is less likely to develop fatigue cracks under long-term alternating loads, meeting the design life requirement of over 20 years for the gearbox.

3. Optimize material utilization and reduce manufacturing costs

Forging process can achieve near-net forming of the output shaft through custom molds, that is, the forging blank only needs a small amount of fine processing to meet the final size requirements. Compared with traditional cutting processing, the material utilization rate can be increased by 20% to 40%, while reducing processing time and lowering manufacturing costs. Especially for output shafts with complex structures (such as those with multiple sets of splines and steps), forging processes can precisely form complex structures, avoiding material waste caused by extensive cutting.

4. Compatible with mass production to ensure consistent quality

The demand for gearboxes in the industrial sector is characterized by large-scale production. The forging process can be mass-produced through die forging equipment. Combined with digital twin and intelligent detection technologies, parameters such as heating temperature, forging pressure, and cooling speed can be precisely controlled to ensure that the material performance and dimensional accuracy of each output shaft remain consistent, meeting the requirements for large-scale assembly of gearboxes.

Iv. Manufacturing and Quality Control of output shaft: The entire process from forging to finished products

The production of high-end output shaft requires going through multiple strict processes, each of which directly affects its performance and reliability. The core processes are as follows:

1. Raw material screening: Laying the foundation for quality

Give priority to using high-strength alloy structural steel billets that meet the standards. These billets need to pass composition testing and mechanical property tests to ensure they are free of harmful substances and internal inclusions, providing high-quality base materials for forging processes.

2. Forging process implementation: Core forming stage

Blanking: Precisely cut the blank according to the size of the output shaft to ensure that the weight and volume errors are within the allowable range.

Heating: Heat the billet to the forging temperature of 800-1200℃ to ensure that the metal plasticity reaches the best state.

Forging forming: The die forging process is adopted (some large output shafts use free forging), and the blank is pressed into the preset shape through pressure equipment to achieve the initial forming of the shaft body, splines, flanges and other structures.

Cooling: Slow cooling is adopted to avoid internal stress and cracks caused by rapid cooling, ensuring the uniformity of the internal structure of the forging.

3. Subsequent processing: Optimize precision and performance

Rough machining: Remove the oxide scale and excess allowance from the forging blank, and preliminarily process key dimensions such as the shaft diameter and length.

Heat treatment: The comprehensive mechanical properties are enhanced through quenching and tempering (quenching + high-temperature tempering), and the surface is treated with nitriding, high-frequency quenching and other processes to increase hardness and wear resistance.

Precision machining: Precision machining is carried out using equipment such as CNC lathes, grinders, and spline milling machines to ensure that dimensional tolerances and positional tolerances meet the design standards.

Surface treatment: Anti-rust treatment is carried out through processes such as phosphating and galvanizing to adapt to different usage environments.

4. Quality Inspection: Strict control at every level

Dimensional inspection: Utilizing equipment such as three-coordinate measuring machines and spline detectors, 100% inspection is conducted on key parameters including shaft diameter, spline tooth profile, and coaxiality.

Non-destructive testing: Internal cracks, inclusions and other defects that may occur during the forging process are identified through UT and magnetic particle testing MT.

Performance testing: Sampling is conducted for hardness testing, tensile strength testing, and fatigue testing to ensure that the product meets the usage requirements of gearbox.

Assembly test: Assemble the finished output shaft with the gearbox gears, bearings and other components to test the power transmission efficiency and operational stability.

V. Typical Application Scenarios of output shaft

As the core component of gearbox, the application scenarios of output shaft highly overlap with those of gearbox, covering multiple industrial fields:

The automotive industry

In passenger vehicles: In manual transmissions, automatic transmissions, and dual-clutch transmissions, the output shaft transmits power to the drive shaft to drive the wheels to move, which needs to be adapted to frequent start-stop and sudden acceleration conditions.

Commercial vehicles: The output shafts of gearboxes in heavy-duty trucks and buses need to withstand greater torque. They mostly adopt high-strength shafts made by forging technology to ensure the reliability of power transmission during heavy-load transportation.

2. Construction machinery field

In the gearboxes of excavators, loaders, cranes and other equipment, the output shaft drives the working devices (buckets, booms) to rotate and needs to withstand instantaneous heavy loads and impact loads. The high-strength characteristics of forged output shafts can meet the requirements of harsh working conditions.

3. Industrial machinery field

In equipment such as wind power gearboxes, machine tool gearboxes, and conveyor belt gearboxes, the output shaft needs to operate stably for a long time and transmit constant torque. The fatigue resistance performance endowed by forging technology can extend the service life of the equipment.

4. Agricultural machinery field

In the gearboxes of agricultural equipment such as tractors and harvesters, the output shafts need to adapt to the frequent load changes in complex field road conditions. Forging the toughness and wear resistance of the output shafts can ensure the continuous operation capacity of the equipment.

Vi. Industry Development Trends: Synergistic Upgrading of output shaft and Forging Technology

With the transformation of the industrial field towards high efficiency, energy conservation and intelligence, gearbox's performance requirements for the output shaft are constantly increasing, promoting the coordinated upgrade of the output shaft and forging technology:

1. Balancing lightweight and high strength

By combining new forging materials (such as high-strength aluminum alloys and composite materials) with precision forging processes, the weight is reduced while ensuring the strength of the output shaft, lowering the overall energy consumption of the gearbox and meeting the energy-saving requirements of fields such as new energy vehicles and wind power.

2. Intelligent integrated design

Sensors (temperature, vibration and stress sensors) are integrated on the output shaft to monitor the operating status and wear degree in real time. Data is transmitted to the intelligent operation and maintenance platform through the Internet of Things to achieve fault early warning and predictive maintenance, reducing downtime losses.

3. Digitalization and greening of forging processes

Introduce industrial robots and digital twin technology to achieve digital control of the entire forging process, enhancing production efficiency and quality consistency. At the same time, energy-saving heating equipment is adopted and forging waste is recycled and reused to promote the development of forging processes towards a green and environmentally friendly direction.

Summary

The output shaft, as the core actuating component of the gearbox, its core function is to precisely transmit the torque and rotational speed converted by the gearbox. It is the "last mile" of power output in the mechanical system. The forging process endows the output shaft with the core capability to adapt to complex working conditions by enhancing material properties, ensuring structural integrity, and improving precision stability. The deep integration of the two is the key guarantee for the efficient, stable and long-term operation of the transmission.

From the driving of automobiles to the operation of construction machinery, from wind power generation to machine tool processing, the output shaft empowered by forging has always played a key role behind the scenes. In the future, with the digital upgrade of forging technology, the application of new materials and the implementation of intelligent design, output shafts will further achieve performance iterations, injecting strong impetus into the high-quality development of the gearbox industry and supporting the efficient operation of the global industrial sector.