Difference Between Shaft And Spindle In Industry Application

Difference Between Shaft And Spindle In Industry Application

In the field of industrial transmission and mechanical manufacturing, shaft and Spindle are two types of core components. Although they have similar appearances and both undertake the functions of power transmission or load bearing, there are significant differences in structural design, working characteristics and application scenarios. Among them, Planetary Reducer Spindle and Support Shaft, as typical representatives of the two types of components, are widely used in planetary reducers, machine tools, construction machinery and other equipment. Clarifying the differences between the two is of great significance for equipment selection, maintenance and performance optimization.

I. Core Definitions and Essential Differences

1. The definition and core attributes of Shaft

shaft is a cylindrical component in machinery used to transmit power, torque or support rotating parts. Its core functions are "transmission" and "support". Support Shaft, as a common type of shaft, mainly undertakes the function of supporting other moving parts. Its own rotational speed is relatively low or it only rotates passively with the parts. The requirements for coaxiality and rigidity are mainly to meet the stability of support.

This type of shaft structure is relatively simple, mostly smooth shafts or stepped shafts with keyways. The material is mainly medium carbon alloy steel, and the processing technology focuses on turning and grinding to ensure that the surface roughness and dimensional accuracy meet the assembly requirements. In the transmission system, shaft often connects the power source with the actuator through couplings, gears and other components, transmitting torque from motors, engines, etc. to the working parts, or supporting rotating parts such as gears and bearings to maintain stable operation.

2. Definition and Core Attributes of Spindle

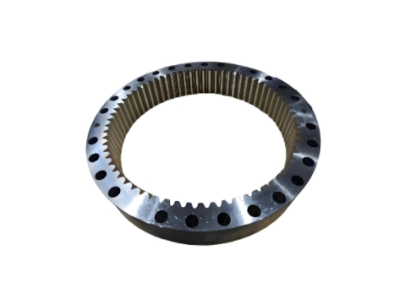

Spindle specifically refers to a core shaft component that rotates at high speed and directly drives the working part or transmits high-precision power. Its core functions are "high-precision drive" and "high-speed rotation". Planetary Reducer Spindle is a typical application of Spindle. It not only needs to transmit the output torque of the planetary reducer, but also needs to ensure precise meshing with the sun gear and planetary gears during high-speed rotation. The requirements for rotational speed, rigidity and rotational accuracy far exceed those of ordinary shafts.

Spindle has a more complex structure, often integrating precision bearings, lubrication channels, cooling systems, etc. Its materials are mostly high-strength alloy steels and undergo heat treatment processes such as carburizing, quenching, and nitriding to enhance hardness, wear resistance, and fatigue resistance. Its processing accuracy requirements are extremely high, especially the radial runout and end face circular runout need to be controlled at the micrometer level to meet the demands of high-speed and high-precision operations.

Ii. Differences in Structural Design and Processing Technology

1. The structure and processing characteristics of Shaft

The structural design of the common shaft and the Support Shaft takes "practical adaptation" as the core and does not require complex auxiliary systems. For instance, in construction machinery, the support shaft only needs to be designed with a stepped structure to accommodate the installation of bearings, and power transmission is achieved through keyways with components such as gears and sprockets, without the need for additional integrated lubrication or cooling devices.

In terms of processing, shaft takes turning and grinding as its core processes. For some complex shafts, additional procedures such as keyway milling and drilling are added. The processing accuracy is usually controlled at IT6-IT8 levels, and a surface roughness of Ra≤1.6μm can meet the usage requirements. Material selection should be adjusted according to the force conditions. For light-load scenarios, 45 # steel can be used, while for heavy-load scenarios, alloy steels such as 40Cr should be adopted. There is no need to overly pursue high strength or high-precision processing, which can reduce manufacturing costs.

2. The structure and processing characteristics of Spindle

The structural design of Spindle and Planetary Reducer Spindle centers around "high precision and high-speed rotation", and needs to take into account rigidity, vibration damping and heat dissipation. Take Planetary Reducer Spindle as an example. Its spindle body needs to be designed with precise gear installation grooves to precisely match the tooth profiles of planetary gears and sun gears. At the same time, it integrates precision rolling bearings or sliding bearings to ensure rotational accuracy during high-speed rotation.

In terms of processing technology, Spindle needs to go through multiple procedures such as rough turning, fine turning, rough grinding, fine grinding, and ultra-fine grinding. Some high-end Spindles also require honing and grinding treatments. The processing accuracy can reach IT3-IT5 grades, and the radial runout is controlled within 0.001-0.005mm. The materials are mostly high-strength alloys such as Cr15 and 38CrMoAl. After heat treatment, the surface hardness can reach above HRC55. At the same time, it has passed dynamic balance tests to reduce vibration during high-speed rotation and ensure operational stability.

Iii. Differences in Application Scenarios and Functional Adaptation

1. Typical application scenarios of Shaft

shaft and Support Shaft are widely used in the basic transmission and support systems of various types of machinery, suitable for scenarios with medium and low speeds and medium and low precision requirements

General machinery: The drive shafts in water pumps and fans transmit motor power through the shaft, driving the impeller to rotate.

Construction machinery: Support shafts for excavators and cranes, supporting hydraulic motors, gearboxes and other components to maintain movement stability;

Transmission equipment: Drive shafts of belt conveyors and chain conveyors, which transmit power and support the operation of the conveyor belt.

In the home appliance industry: Drive shafts in washing machines and air conditioner compressors are used to achieve power transmission and component support.

In such scenarios, shaft does not require high-speed rotation or high-precision positioning. Its core demands are reliable torque transmission and stable support components. Cost-effectiveness and compatibility are the key factors in selection.

2. Typical application scenarios of Spindle

Spindle and Planetary Reducer Spindle is mainly applied in high-speed and high-precision transmission or processing scenarios, with extremely high requirements for rotational accuracy, rigidity and stability.

Planetary Reducer: As the core transmission component, the Planetary Reducer Spindle meshes with the planetary gears during high-speed rotation, precisely transmitting the decelerated torque to the output end to ensure the transmission efficiency and accuracy of the reducer.

Machine tool equipment: The spindles of CNC machine tools and machining centers directly drive the cutting tools for cutting processing. Their rotational accuracy determines the dimensional tolerance and surface quality of the parts processed.

New energy equipment: The main shaft of the wind turbine speed increaser converts the low-speed rotation of the wind turbine into the high-speed rotation of the generator, and it needs to maintain high-precision operation under heavy load.

Precision transmission: The robot joints and the spindle of the servo motor achieve high-precision power transmission and attitude control, supporting the robot to complete complex movements.

Iv. Core Considerations for Selection and Maintenance

1. Selection principles

If the requirements are medium and low-speed power transmission and component Support, and the precision requirements are not high, shaft or Support Shaft should be preferred, and the material and size should be selected according to the load size.

If high-speed rotation and high-precision transmission are involved (such as Planetary reducers, machine tool processing), Spindle or Planetary Reducer Spindle should be selected, with a focus on rotational accuracy, rigidity and speed adaptability.

When selecting the type, it is necessary to match the working conditions of the equipment. For example, in heavy-load scenarios, the strength of the shaft should be enhanced, and in high-speed scenarios, the vibration damping and heat dissipation design of the Spindle should be optimized.

2. Maintenance points

Shaft maintenance: Regularly inspect the wear and deformation of shaft, promptly replace worn bearings and seals, ensure adequate lubrication, and prevent damage caused by dry friction.

Spindle maintenance: Planetary Reducer Spindle requires regular detection of rotational accuracy and vibration values, replacement of dedicated lubricating grease, and cleaning of cooling channels to prevent performance from being affected due to overheating or poor lubrication during high-speed rotation.

Both types of components need to avoid overloading operation, undergo regular precision calibration to extend their service life.

Summary

Although both shaft and Spindle belong to shaft components, they differ significantly in definition, structure, process, and application scenarios: shaft focuses on medium and low-speed, medium and low-precision power transmission and Support, and Support Shaft is its typical representative. Spindle focuses on high-speed and high-precision drives, and Planetary Reducer Spindle demonstrates its core value in precision transmission. Clarifying the differences between the two can help enterprises make precise selections, optimize equipment performance and reduce maintenance costs. Against the backdrop of the rapid development of industrial automation and precision manufacturing, the trend of specialization and high precision for the two types of components will become more pronounced, continuously providing support for efficient production in various industries.