Replacement Excavator Booms & Arms for Construction

Replacement Excavator Booms & Arms for Construction

In the field of construction, the operation efficiency and service life of excavators largely depend on the performance of core components. Among them, boom and arm excavator, as the key structure that directly bears the working load, their wear and replacement are unavoidable problems in the construction process. High-quality replaceable excavator boom and boom not only restore the equipment's operational capacity but also upgrade performance according to construction requirements, adapting to different operational tasks in various scenarios. Whether it is the precise replacement of excavator arm parts or the overall replacement of digger boom arm, scientific selection is required in combination with the equipment model and construction conditions. The special structural design of excavator swing boom poses strict requirements for the compatibility of replacement parts.

I. The Value of the Core Functions of the boom and the moving arm of a replaceable excavator

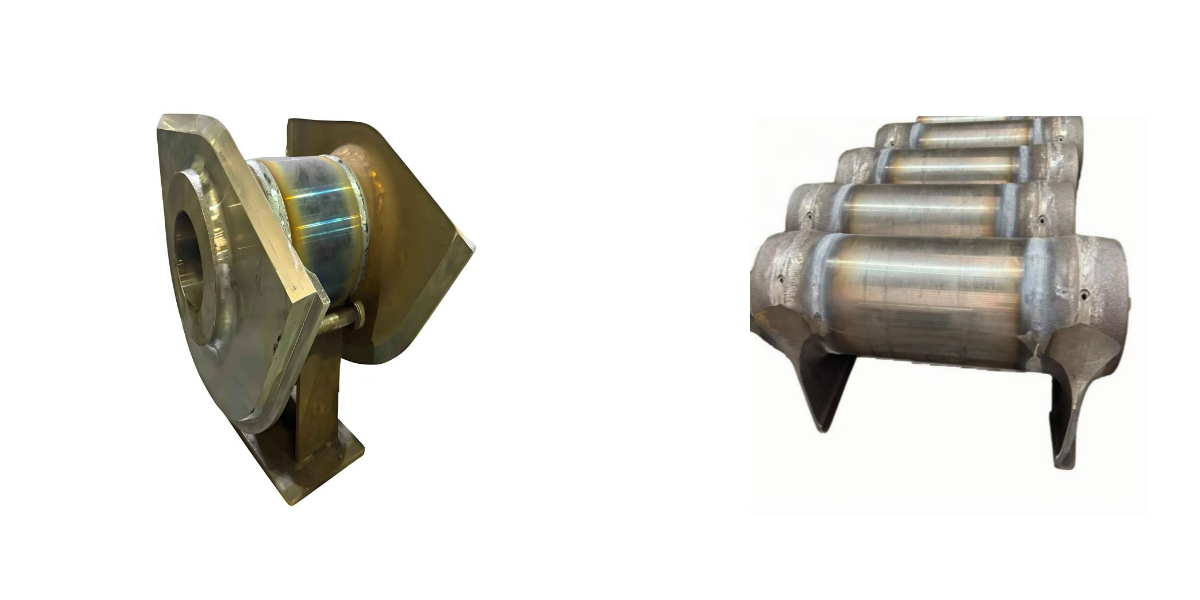

For excavators that are in a state of high-intensity operation for a long time, boom and arm excavator are prone to problems such as wear, deformation and cracking. If not replaced in time, it may lead to a decrease in operation accuracy, an increase in safety risks, and even cause equipment failure. The core value of the replaceable boom and boom lies in the rapid restoration of equipment performance and the guarantee of construction progress. High-quality digger boom arm replacement parts are made of high-strength alloy materials and undergo precise processing and heat treatment processes. They can withstand load impacts under complex working conditions, and their service life can even be comparable to that of original factory components.

Meanwhile, in response to different construction requirements, replacing components can also achieve functional upgrades. For example, to adapt to the high-altitude operation scenario, excavator swing boom can be replaced to increase the rotation operation range of the equipment; By replacing the compatible excavator arm parts, such as reinforced pins, wear-resistant bushings, etc., the connection stability of boom and arm excavator can be enhanced and the subsequent maintenance cost can be reduced. In the rental market, long boom excavator for rent can quickly restore rental capacity and reduce downtime losses by timely replacement of high-quality replacement parts if the large arm is damaged.

Ii. Different types of scenarios for replacing the large arm and the boom

According to the model of the excavator and the operational requirements, the replaceable boom and boom are divided into various types, and they need to be precisely matched to achieve the best performance. For the long boom mini excavator commonly used in small-scale construction projects, when replacing the digger boom arm, both flexibility and lightweight should be taken into account to avoid affecting the ease of operation of the equipment due to overly heavy components. The replacement parts of the two piece boom excavator should focus on the connection accuracy of the two sections of the arm to ensure smooth folding and extension movements and adapt to the operation requirements in narrow Spaces.

In special operation scenarios, the replacement boom of excavator with extendable boom needs to have precise telescopic function, and its excavator arm parts such as hydraulic cylinders and seals need to meet the high-pressure working environment to avoid leakage problems. mini excavator truss boom as a special operation component, when replacing it, it is necessary to ensure the strength and stability of the truss structure, and it is suitable for special tasks such as hoisting and high-altitude operations. Furthermore, the replacement of excavator swing boom needs to be combined with the parameters of the rotary mechanism of the equipment to ensure the accuracy of the rotary Angle and power transmission and meet the requirements of multi-directional operation.

Iii. Selection Principles and Quality Judgment Criteria for Replacement Parts

When selecting the model, it is necessary to first clarify the core parameters such as the model, rated load and operating scenario of the excavator, and ensure that the boom and arm excavator to be replaced are fully compatible with the equipment body. For example, when selecting the long boom mini excavator, it is necessary to check the length and weight of the boom against the carrying capacity of the equipment to avoid reduced operation efficiency or equipment damage due to component mismatch. Meanwhile, products that comply with industry standards should be given priority. Focus on checking the machining accuracy of excavator arm parts, such as tooth profile meshing degree, coaxiality of shaft components, etc.

In terms of quality judgment, a comprehensive assessment can be made through material quality, process details and test reports. The surface of high-quality digger boom arm should have no obvious defects, the welds should be uniform and firm, and the hardness index after heat treatment should meet the design requirements. For excavator swing boom, it is necessary to check the sealing and flexibility of the rotary joint to ensure there is no jamming or leakage. In addition, the after-sales service of the supplier should also be taken into consideration. It is advisable to give priority to brands that can provide installation guidance and warranty services, so as to solve problems in a timely manner when they occur during subsequent use. For the replacement parts of the two piece boom excavator, it is necessary to verify the folding clearance and interlocking performance of the two sections of the arm to ensure compliance with the construction operation requirements.

Iv. Precautions for Installation and Maintenance of Replacement Parts

During the installation process, operate strictly in accordance with the equipment manual to ensure that the connection parts of boom and arm excavator are precisely aligned and the bolt tightening torque meets the standard. When installing excavator arm parts, such as pins, bushings, etc., special grease should be applied to reduce motion friction and extend the service life of the components. For excavator swing boom, a rotation test should be conducted after installation, and the parameters of the hydraulic system should be adjusted to ensure that the rotation speed and torque meet the design standards.

In terms of maintenance, regular inspections of the replaced boom and boom should be carried out, with particular attention to the wear of the connection parts, the sealing of the hydraulic pipelines, and the working condition of the excavator arm parts. After high-intensity operation, it is necessary to clean the impurities on the surface of the components in time and replenish the lubricating grease to prevent rusting and accelerated wear. for leased equipment such as long boom excavator for rent, regular maintenance files should also be established to record the usage time and wear and tear of components, and the replacement cycle should be planned in advance to reduce the occurrence of sudden failures. For the telescopic mechanism of excavator with extendable boom, it is necessary to regularly check the quality and quantity of the hydraulic oil to ensure the stability and reliability of the telescopic function.

V. Innovation Directions of Replacement Components under Industry Development Trends

As the construction industry moves towards high efficiency, intelligence and greenness, the boom and boom of replaceable excavators are also constantly innovating and upgrading. In terms of materials, the application of new high-strength lightweight alloys is becoming increasingly widespread, which can not only enhance the load-bearing capacity of digger boom arm, but also reduce the energy consumption of equipment. In terms of craftsmanship, the promotion of technologies such as precision casting and robot welding has further improved the machining accuracy and consistency of excavator arm parts and prolonged the service life of the components.

Intelligent upgrade has also become an important development direction. Some high-end replacement parts integrate sensor technology, which can monitor the load, temperature and other data of boom and arm excavator in real time, and feed back to the operators through the Internet of things system to achieve fault early warning and precise maintenance. The demand for customized products for special scenarios continues to grow, such as environmentally friendly components suitable for new energy excavators, enhanced excavator swing boom designed for extreme working conditions, etc. Meanwhile, the functions of specialized components such as mini excavator truss boom have been continuously optimized, which will be more precisely adapted to the demands of niche operations and provide strong support for the efficient development of the construction industry.