Sealed vs. Non-Sealed Oil Tanks: Key Differences and Applications?

Sealed vs. Non-Sealed Oil Tanks: Key Differences and Applications?

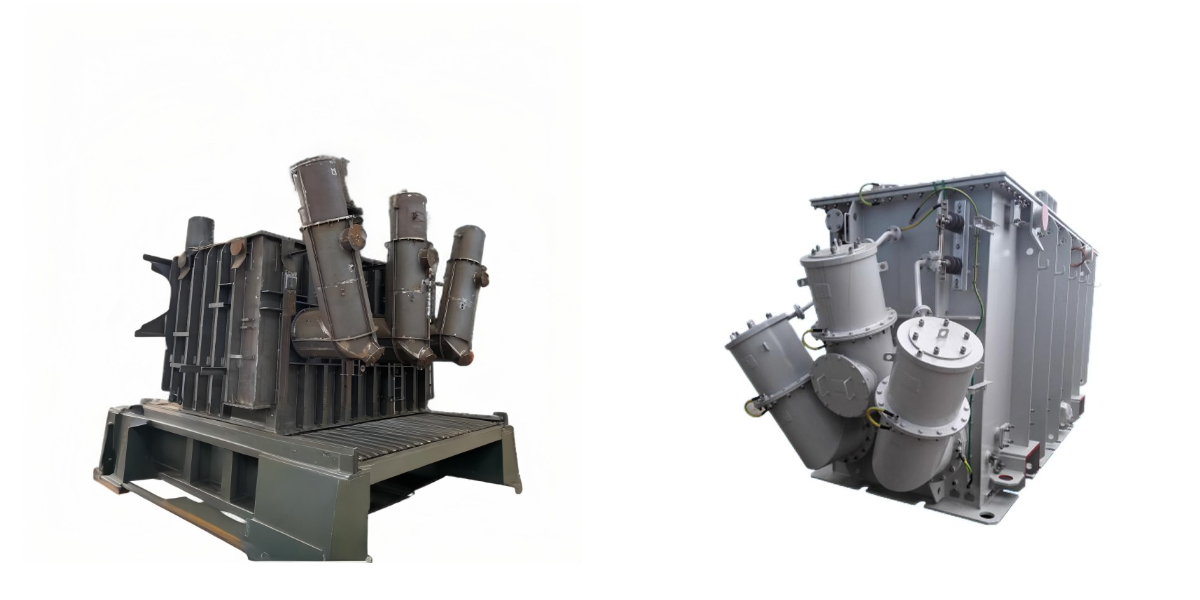

In the field of industrial Oil storage and equipment matching, Sealed Oil Tanks and Non-Sealed oil Tanks are two types of core oil storage components. Due to the differences in sealing design, they form distinct distinctions in protective performance and applicable scenarios. While welding parts serve as the key connection units of the oil tank structure, and oil tank transformer and transformer oil tank shell act as the core application carriers. It directly affects the performance and compatibility range of the two types of fuel tanks. A thorough analysis of the differences between the two can provide a scientific basis for the selection and operation and maintenance of industrial equipment.

I. Core Differences in Structural Design: Sealing Logic and Welding process

1. Sealed fuel tank: Fully enclosed structure + high-precision welding

The sealed oil tank is designed with the core concept of "completely isolating the external environment". The entire tank body is in a closed state and only realizes oil injection, oil discharge and pressure regulation through dedicated interfaces. The structural stability and sealing performance of it completely depend on the processing accuracy of the welding parts - key parts such as box splicing, pipe interfaces, and inspection ports need to adopt high-precision processes such as argon arc welding and submerged arc welding to ensure that there are no pores or cracks in the weld seams and achieve seamless sealing.

In the oil tank transformer, the sealed design is particularly crucial. The transformer oil tank shell, as the core load-bearing component of the oil tank, needs to be fabricated into a fully enclosed cavity through high-quality welding parts to completely isolate the transformer oil from air, moisture and dust. Some high-end products will also integrate components such as pressure relief valves and silicone respirators on the transformer oil tank shell to further enhance sealing protection and meet the requirements of long-term continuous operation.

2. Non-sealed fuel tank: Open structure + foundation welding

Non-sealed fuel tanks adopt a semi-open design. They usually have vent holes or openable fuel caps on the top, allowing natural air circulation between the inside and outside of the tank and balancing the internal and external air pressure. The application of its welding parts only focuses on basic structures such as box splicing and bracket fixation, with relatively low requirements for welding sealing. There is no need for complex seamless welding processes, and the structural design is simpler.

The welding parts of this type of fuel tank mainly undertake the function of structural support. The material is mostly ordinary carbon steel, and the welding process is mainly manual arc welding, which has a lower manufacturing cost. Although the design of the vent hole can prevent pressure fluctuations caused by changes in oil temperature, it also exposes the oil directly to the external environment, and its protective performance is relatively limited.

Ii. Key Performance Comparison: Protection, Stability and Maintenance Cost

1. Protective performance: Sealed type isolates contamination, while non-sealed type is easily affected

Sealed fuel tank: Relying on the high-precision welding of welding parts and the fully enclosed structure, it can effectively prevent the invasion of moisture, dust and impurities, and at the same time prevent the evaporation or leakage of oil. For the oil tank transformer, this kind of protection can prevent the oxidation and deterioration of transformer oil, ensure its insulation and cooling performance, and extend the service life of the transformer oil tank shell and internal components.

Non-sealed fuel tanks: The open structure makes their protective ability relatively weak. Air and moisture can easily enter the fuel tank through the vent holes, causing oxidation and contamination of the oil. Its welding parts do not need to bear the responsibility of sealing. It only needs to ensure the integrity of the structure. However, the oil is prone to deterioration after long-term use and requires frequent maintenance.

2. Operational stability: The sealed type is suitable for harsh working conditions, while the non-sealed type is applicable to ordinary scenarios

Sealed fuel tank: The closed environment makes the performance of the oil more stable and can adapt to harsh working conditions such as high temperature, high humidity and much dust. During the operation of the oil tank transformer, when the transformer oil heats up and expands, the transformer oil tank shell can balance the internal and external pressures through the pressure regulating device to avoid deformation of the tank. The high-strength design of the welding parts ensures the stability of the structure under pressure changes.

Non-sealed fuel tank: Only suitable for normal temperature, normal pressure and clean ordinary environment. If the ambient temperature fluctuates sharply or there is a lot of dust, problems such as oil overflow and contamination are likely to occur. welding parts may also become loose and rusted due to repeated thermal expansion and contraction, affecting operational stability.

3. Maintenance cost: The initial investment for sealed types is high, while the long-term cost for non-sealed types is high

Sealed fuel tanks: They have extremely high requirements for the material of welding parts (mostly high-strength alloys) and welding processes, and the initial manufacturing cost is relatively high. However, the sealing structure reduces oil loss and contamination, has a long maintenance cycle, and only requires regular inspection of the integrity of welding parts and seals. The long-term maintenance cost is relatively low.

Non-sealed fuel tank: welding parts has a low processing threshold, low cost and less initial investment. However, the oil is prone to oxidation and deterioration, requiring frequent replacement of the oil and filter elements. Moreover, the welding parts are prone to rust and damage, necessating regular inspection and reinforcement. The long-term maintenance cost is higher than that of sealed oil tanks.

Iii. Core Application Scenarios: Adapt to industrial demands on demand

Sealed fuel tank: Focusing on the demands of high precision and high reliability

Power industry: oil tank transformer is the core application scenario of sealed oil tanks. transformer oil tank shell achieves full sealing through high-quality welding parts to ensure the insulation performance of transformer oil. It is suitable for equipment such as power plants and substations that need to operate continuously for a long time, avoiding malfunctions caused by oil quality issues.

High-end mechanical equipment: aerospace, precision hydraulic systems, deep-sea operation equipment, etc., have extremely high requirements for the cleanliness and stability of the oil. The welding parts of the sealed fuel tank are welded with high precision, which can prevent the influence of the external environment on the oil and ensure the transmission accuracy and service life of the equipment.

In the chemical industry, when storing flammable, explosive, volatile or easily oxidized oil media, the sealed oil tank builds an explosion-proof sealing structure through welding parts to prevent oil and gas leakage and safety accidents, and at the same time prevent the deterioration of the medium.

2. Non-sealed fuel tank: Suitable for ordinary working conditions and low-cost requirements

General machinery: small machine tools, agricultural machinery, ordinary hydraulic equipment, etc., have relatively low requirements for oil cleanliness. Non-sealed oil tanks can meet the basic oil storage needs. Its welding parts do not require complex processing, have low manufacturing costs, are easy to maintain, and are suitable for mass production scenarios.

Normal temperature and pressure storage: Temporary oil storage in industrial workshops, lubricating oil tanks for small equipment, etc. The environment is stable and there are no strict protection requirements. The open structure of the non-sealed fuel tank facilitates rapid refueling and draining. When welding parts are damaged, they are easy to replace, meeting the usage requirements of low cost and high efficiency.

Short-term operation equipment: Temporary construction machinery, small-scale engineering machinery and other short-term operation equipment, choosing non-sealed oil tanks can reduce procurement costs, and are easy to maintain, which can reduce equipment downtime losses.

Iv. The Decisive Role of welding parts in the Performance of Fuel Tanks

Welding parts are the core for connecting various components of the fuel tank. Their quality directly affects the structural strength, sealing performance and service life of the fuel tank, which is particularly crucial in oil tank transformer and transformer oil tank shell.

Sealed fuel tank: Corrosion-resistant and high-strength alloy welding parts should be selected, combined with high-precision welding processes to ensure that the weld seams are seamless and defect-free. In the transformer oil tank shell, if the welding quality of the welding parts is poor, it will lead to the failure of the seal. Moisture and air will invade and cause the deterioration of the transformer oil, thereby affecting the insulation performance of the oil tank transformer and even causing short-circuit faults.

Non-sealed fuel tank: welding parts do not need to undertake the sealing function, but it is necessary to ensure structural stability to avoid tank deformation or oil leakage. Ordinary carbon steel welding parts are usually selected, and processes such as manual arc welding are adopted to control costs while meeting the structural strength requirements.

V. Practical Suggestions for Selection and Maintenance

1. Selection principles

If it is used for the oil tank transformer, precision equipment or harsh environments (storage of high temperature, high humidity, dust, flammable and explosive media), the sealed oil tank should be preferred, and the quality of welding parts and sealing process of the transformer oil tank shell should be checked with emphasis.

If it is used for general machinery, short-term operations or low-cost demand scenarios, non-sealed fuel tanks can be selected, with emphasis on the structural strength and ease of maintenance of welding parts.

When selecting the type based on the characteristics of the medium: When storing easily oxidized, volatile, flammable and explosive media, a sealed oil tank must be chosen. When storing ordinary lubricating oil in a clean environment, non-sealed oil tanks are more cost-effective.

2. Maintenance points

Sealed fuel tank: Regularly inspect the integrity of welding parts and seals, and test the sealing performance through pressure tests; Regularly monitor the oil quality, and replace the aged gasket or damaged welding parts in time to avoid seal failure.

Non-sealed fuel tanks: Regularly clean impurities from vent holes and fuel filling ports, and check whether the welding parts are rusted or loose. Shorten the oil replacement cycle, install filter elements to enhance the oil cleanliness, and reduce the wear of impurities on the equipment.

Summary

The core differences between sealed fuel tanks and non-sealed fuel tanks are reflected in the sealing design, protective performance and applicable scenarios. welding parts, as the structural core, directly determines the reliability of the two types of fuel tanks. oil tank transformer and transformer oil tank shell are typical high-end application scenarios of sealed oil tanks. The sealed fuel tank, with its fully enclosed design and high-precision welding parts, is suitable for harsh working conditions and high-precision equipment requirements. Non-sealed oil tanks, with their advantages of low cost and easy maintenance, meet the basic oil storage requirements of ordinary machinery.

In industrial applications, a comprehensive selection should be made based on the type of equipment, environmental conditions, and medium characteristics. At the same time, quality control and regular maintenance of welding parts should be emphasized to maximize the utilization value of the oil tank and reduce the operational risks of the equipment. With the increasing requirements for precision and stability in industrial manufacturing, the application of sealed fuel tanks in high-end equipment will continue to expand. The process upgrade of welding parts and the design optimization of transformer oil tank shell will also further promote the iterative upgrade of fuel tank performance.