What Are Mining Dumbbell Pins? Uses, Materials & Key Specifications

What Are Mining Dumbbell Pins? Uses, Materials & Key Specifications

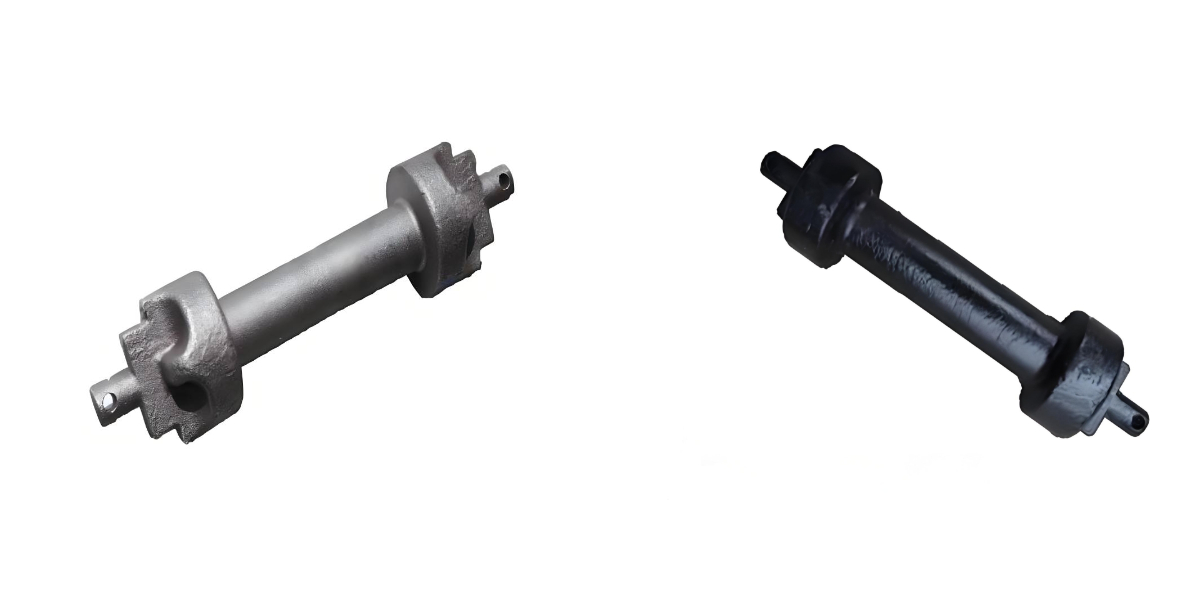

Among the heavy equipment in Mining, Mining Dumbbell Pins are the key components to ensure the stable operation of machinery and are often used in combination with Mining Dumbbell Shaft and Dumbbell Link pins. The three together form the core connection structure of the mine conveying system.

I. Core Definition and Function of Mining Dumbbell Pins

Mining Dumbbell Pins are cylindrical connectors shaped like dumbbells, mainly used for the connection of chain links in equipment such as mine scraper conveyors and transfer machines. It can precisely connect the Mining Dumbbell Shaft with the Dumbbell Link Pin, transfer the traction force during the operation of the equipment, and buffer the impact load during the ore conveying process at the same time. As a key Heat-treated mining connector, its strength directly determines the operational safety of the equipment and avoids downtime accidents caused by component breakage.

Ii. Typical Application Scenarios of Mining Dumbbell Pins

In underground Mining, Mining Dumbbell Pins are widely used in the chain connection of scraper conveyors to ensure that the scrapers can stably convey ores. In the crushing system of open-pit mines, it cooperates with Dumbbell Link Pin to connect the transmission components of the conveyor belt. Furthermore, when components of the equipment wear out, Mining Dumbbell Pins are also important Mining pin replacement parts, which can quickly repair the equipment and reduce downtime.

Iii. Preferred Materials and Processes for Mining Dumbbell Pins

High-quality Mining Dumbbell Pins are mostly made of 40Cr alloy structural steel or 20Mn2 material and are produced through quenching and tempering heat treatment. The hardness of this Heat-treated mining connector can reach HRC28-32, and it has excellent wear resistance and fatigue resistance. During production, phosphating treatment will also be carried out on the surface to enhance the anti-rust ability, adapt to the harsh humid and dusty environment of the mine, and extend the overall service life of the Mining Dumbbell Shaft and Dumbbell Link Pin.

Iv. Key Technical Parameters of Mining Dumbbell Pins

When purchasing Mining Dumbbell Pins, three core parameters need to be paid attention to: The first is the diameter, which needs to match the aperture of the Mining Dumbbell Shaft and Dumbbell Link Pin. The common specifications are 30-80mm; The second is the length, which is determined based on the pitch of the chain to ensure there is no loosening after connection. The third is the tensile strength, which should be ≥800MPa to meet the requirements of heavy loads. When used as Mining pin replacement parts, the parameters need to be strictly checked to avoid affecting the operation of the equipment due to non-compliance with specifications.

In conclusion, the synergy of Mining Dumbbell Pins with Mining Dumbbell Shaft and Dumbbell Link Pins Combined with the high-performance materials of Heat-treated mining connectors and the compatible Mining pin replacement parts, it can provide reliable connection guarantee for mining equipment and is an indispensable component for the safe production of mines.