Planetary Gear Transmissions | Planetary Gear Solutions

Planetary Gear Transmissions | Planetary Gear Solutions

In the field of industrial transmission, Planetary Gear, with its core advantages of high torque density and compact structure, has become a key component for power transmission in precision equipment. Planetary Gear Transmissions and Planetary Gear Solutions further cover the full chain of services from design, production to application, and are widely adapted to high-end fields such as new energy, robotics, aerospace, etc. This article will comprehensively analyze the technical value and application scenarios of Planetary Gear from dimensions such as the core composition of the transmission system, the characteristics of key components, and the advantages of solutions.

I. Planetary Gear Transmissions: the "efficient power core" for industrial transmission

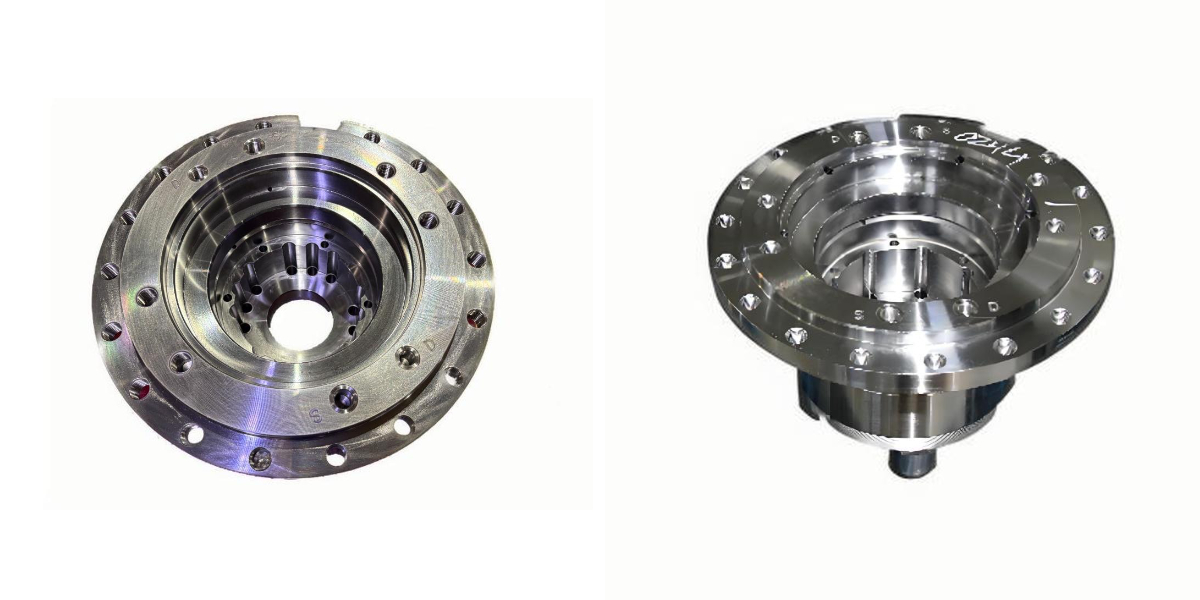

The core of Planetary Gear Transmissions (Planetary Gear transmission system) lies in the ingenious meshing design of Planetary Gear, which consists of four major components: the sun gear, the planet gear, the internal gear ring and the planet carrier. Power is evenly transmitted through multiple sets of planetary gear. Compared with traditional cylindrical gear transmission, it can achieve a larger transmission ratio and torque output in a smaller volume.

In practical applications, the performance of Planetary Gear Transmissions directly depends on the precision of Planetary Gear - high-precision Planetary Gear can increase transmission efficiency to over 95% while reducing vibration and noise, making it suitable for high-speed operation scenarios. For instance, in robot joint drive, Planetary Gear Transmissions, through its multi-tooth meshing feature, can not only transmit sufficient torque to drive the mechanical arm to move, but also ensure the smoothness of the movement and positioning accuracy, thus becoming an indispensable transmission solution in the robot industry.

Ii. Analysis of Key Components: The Core Functions of Planetary reducer Spindle and Support Shaft

A stable Planetary Gear Transmissions is inseparable from the coordinated cooperation of Planetary reducer Spindle and Support Shaft. The two are the "skeleton" components that ensure the efficient operation of Planetary Gear.

1. Planetary reducer Spindle: The "central nervous system" of Torque Transmission

The Planetary reducer Spindle, as the power output core of the Planetary Gear Transmissions, is directly connected to the Planetary Gear and the external load. Its material and machining accuracy are crucial to the transmission stability. Usually, Planetary reducer Spindle is forged from high-strength alloy steel and heat-treated to enhance the surface hardness and toughness. It can withstand the high torque transmitted by Planetary Gear and resist the wear and impact caused by long-term operation at the same time. In the Planetary reducers of wind power equipment, the Planetary reducer Spindle needs to be adapted to megawatt-level torque output. Its design needs to be precisely matched in combination with the number of teeth and module of the Planetary Gear to ensure the lossless transmission of power.

2. Support Shaft: The "stable support" of Planetary Gear

The Support Shaft is mainly used to fix the Planetary carrier and the internal Gear ring of Planetary Gear, ensuring the precise position of Planetary Gear during meshing and avoiding tooth surface wear caused by axial or radial offset. In high-precision Planetary Gear Transmissions, the coaxiality error of the Support Shaft needs to be controlled within 0.005mm. At the same time, high-quality bearings should be matched to reduce running resistance and further improve the transmission efficiency of Planetary Gear. For example, in the Planetary transmission system of precision machine tools, the stability of the Support Shaft directly affects the meshing clearance of the Planetary Gear, and thereby determines the machining accuracy of the machine tool. It is a key component to ensure the accuracy of the equipment.

Iii. Planetary Gear Solutions: Customized to Meet the needs of Multiple industries

High-quality Planetary Gear Solutions not only provides standardized Planetary Gear Transmissions, but also ADAPTS to the working conditions of different industries, Carry out customized design of Planetary Gear, Planetary reducer Spindle and Support Shaft to solve special transmission problems in the industry.

In the field of new energy vehicles, Planetary Gear Solutions will optimize the lightweight design of Planetary Gear for in-vehicle scenarios, use aluminum alloy materials to reduce the overall weight, and at the same time enhance the impact resistance of Planetary reducer Spindle. Adapt to the torque fluctuations during vehicle start-up and braking; In the aerospace field, Planetary Gear Solutions will use high-temperature resistant alloys to build Planetary Gear and Support Shaft to ensure the stable operation of Planetary Gear Transmissions in extreme temperature environments; In the field of heavy machinery, Planetary Gear Solutions will increase the module of Planetary Gear and thicken the Spindle diameter of Planetary reducer to enhance the load capacity of the system and adapt to heavy-load scenarios such as mining and metallurgy.

Iv. Performance Optimization of Planetary Gear: Full-Process Control from Design to Manufacturing

To achieve the best performance of Planetary Gear Transmissions, we need to control the entire process from the design, processing to assembly of Planetary Gear. Among them, the precision control of Planetary reducer Spindle and Support Shaft is particularly crucial.

During the design stage, the meshing process of Planetary Gear needs to be simulated through simulation software to optimize the tooth profile parameters to reduce meshing losses. Meanwhile, the diameter of Planetary reducer Spindle and the Support spacing of Support Shaft are calculated according to the transmission requirements to ensure that the structural strength meets the standards. During the processing stage, Planetary Gear requires the use of a five-axis machining center for precise gear milling to ensure that the tooth surface roughness Ra is ≤0.8μm, while Planetary reducer Spindle and Support Shaft need to undergo grinding processing to improve surface accuracy and fit tolerance. During the assembly stage, it is necessary to ensure the coaxiality of the Planetary Gear and the Planetary reducer Spindle through special tooling, and adjust the preload of the Support Shaft at the same time to avoid the movement of the Planetary Gear during operation.

V. Summary: Future Trends of Planetary Gear Transmissions

With the upgrading of industrial automation and high-end equipment manufacturing, Planetary Gear Transmissions is moving towards higher precision, higher efficiency and lighter weight. The technological innovations of Planetary Gear, Planetary reducer Spindle and Support Shaft will become the core driving force for promoting this trend.

In the future, Planetary Gear Solutions will further integrate digital technologies to achieve the one-piece molding of Planetary Gear's complex structures through 3D printing. The operating status of Planetary reducer Spindle and Support Shaft is monitored in real time through the intelligent monitoring system, and potential faults are warned in advance. Meanwhile, the application of eco-friendly materials and the optimization of energy-saving designs will enable Planetary Gear Transmissions to achieve efficient transmission while meeting the demands of green manufacturing, providing more reliable power support for the high-quality development of various industries.