What is the difference between a stick and a boom excavator? Disassemble the core differences between the boom and the boom of an excavator

What is the difference between a stick and a boom excavator? Disassemble the core differences between the boom and the boom of an excavator

In the field of construction machinery, excavator boom and stick are the "left and right arms" of the working device, but most people have only a vague understanding of the differences between the two. As the core component of the excavator arm parts, the boom on excavator and the boom have essential differences in functional positioning and structural design, which directly affect the operating efficiency and applicable scenarios of the excavator. This article will deeply analyze the differences between the two from four dimensions and help you understand the core construction logic of boom stick excavator.

1. Definition Clarification: The "Identity Boundary" between Boom and Boom

To distinguish the boom from the excavator boom, it is first necessary to clarify the basic positioning of both in the excavator arm parts - although they both belong to the working arm system, they undertake completely different "role divisions".

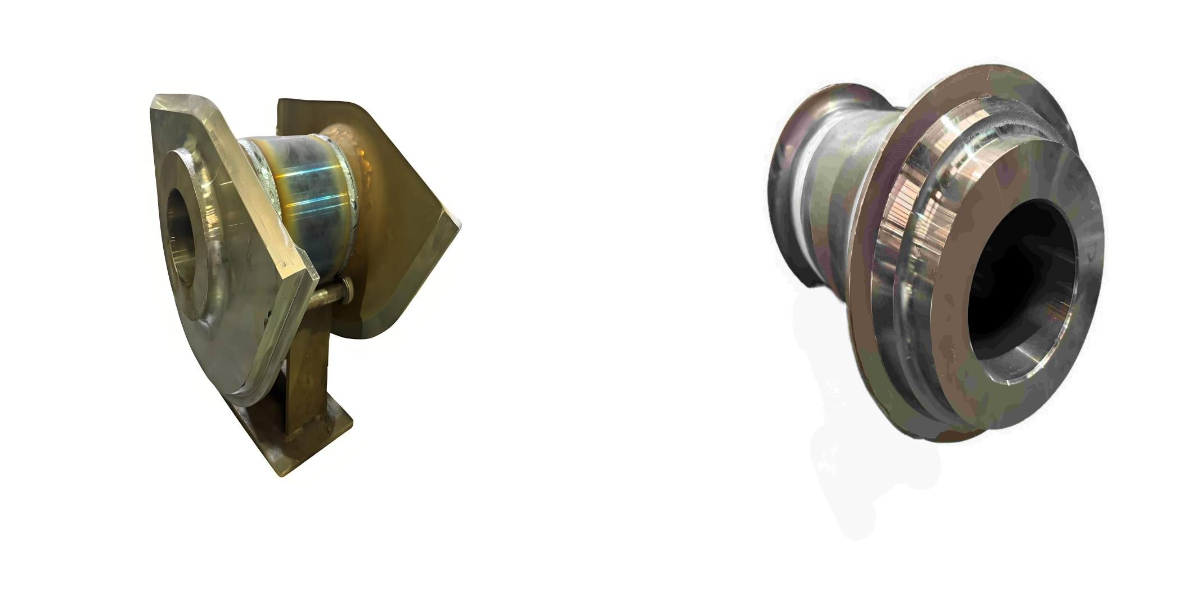

Excavator boom, often referred to as "big arm" in the industry, is a key component connecting the upper chassis of the excavator to the boom, and it is also the "load-bearing core" that links the upper and lower parts in excavator arm parts. Its overall structure is more slender and robust, made of high-strength alloy steel. Its main function is to build the "basic framework" for operations, bearing the entire weight of the bucket rod, bucket and working load. Take mini excavator with extended boom as an example. Although the extended boom design focuses on expanding the working radius, its core identity as the "load-bearing main beam" has never changed.

The boom is called the "forearm", which connects the excavator boom to the bucket and is the "precision actuator" in the excavator arm parts. Compared with the boom, the bucket arm is shorter in length, more flexible in structure, and made of high-strength steel as well. However, it is more precise in weight control to achieve accurate scheduling of the bucket. It is worth noting that some practitioners will collectively refer to the two as "arm boom excavator operating device", but in the professional context, the boom and the bucket arm are independent components, and only when they work together can a complete operating system be formed.

2. Structural Design: The "Performance Game" between Load-bearing Capacity and Flexibility

The structural differences between excavator boom and the boom are entirely determined by their functional requirements, and these differences run through all aspects such as the material, connection method and hydraulic matching of excavator arm parts.

In terms of material and strength, boom on excavator needs to withstand the impact and heavy load during operation. Therefore, thick-walled alloy steel plates are welded together, and reinforcing plates are added at key force-bearing points. For example, the boom plate thickness of large mining excavators can reach 50-80mm, while the boom of mini excavator with extended boom is slightly less thick, but its bending resistance is enhanced by optimizing the cross-sectional shape. Although the bucket rod is also made of high-strength steel, the plate thickness is thinner. The structural design focuses more on the balance of "lightweight + high strength" to enhance the flexibility of movement.

3. Functional Division of Labor: The Synergy Rule of "Main Beam" and "Actuator"

The essential difference between excavator boom and the boom lies in the functional division of labor during operation - they are like the "main beam" and the "actuator", forming a golden pair of "heavy-load support + precise operation".

Excavator boom is the "heavy load bearer" of the operation, leading the construction of the "large-scale operation framework". Its core functions include: bearing the impact force when the bucket is inserted into the material, lifting the bucket rod and the bucket to the target height to complete the loading, and adjusting the working radius and height through extension, retraction or lifting. In the hard soil excavation scenario, the boom on excavator needs to maintain stable support to prevent the excavator arm parts from deforming due to excessive load; The mini excavator with extended boom relies on the extended design of the boom to achieve long-distance operations in narrow Spaces.

4. Scene Adaptation: "Primary and Secondary Switching" under Different Working Conditions

Excavator boom and the importance of the boom will change dynamically with the operation scenarios. This "primary and secondary switching" further highlights the functional differences between the two and also provides a key basis for the selection of boom stick excavator.

In large-scale earthwork projects (such as foundation pit excavation for infrastructure, mine stripping), excavator boom becomes the absolute core. At this point, the boom needs to have an extremely strong load-bearing capacity. For instance, the boom of a mining excavator will adopt an integral forging process, with the plate thickness increased by 30% compared to conventional models to resist rock impact. Although the bucket arm also needs high strength, it is only used as an auxiliary load-bearing component, and the flexibility requirement is relatively low.

In precision operation scenarios such as municipal engineering and garden renovation, the role of the bucket rod is even more crucial. When laying underground pipelines, boom on excavator after fixing the working height, the boom needs to drive the bucket to dig a narrow trench with a width of only 30cm, and the error needs to be controlled within 5cm; When pruning the slope, the bucket shaft needs to adjust the bucket Angle in real time to ensure the flatness of the slope surface. Here, the boom in excavator only serves as the basic support, and the control accuracy of the boom directly determines the quality of the operation.

For narrow-space operations mainly targeted by mini excavator with extended boom (such as indoor demolition, rural house construction), the boom and boom achieve "functional complementarity" : the extended boom breaks through spatial limitations and can extend into narrow alleys or the inner side of high walls; The flexible boom drives the bucket to complete precise excavation, avoiding touching the surrounding buildings. In this scenario, the synergy of excavator arm parts is brought to the extreme, and it also confirms the irreplaceability of the boom and the lever.