Planetary Gears: Types, Uses and Processes

Planetary Gears: Types, Uses and Processes

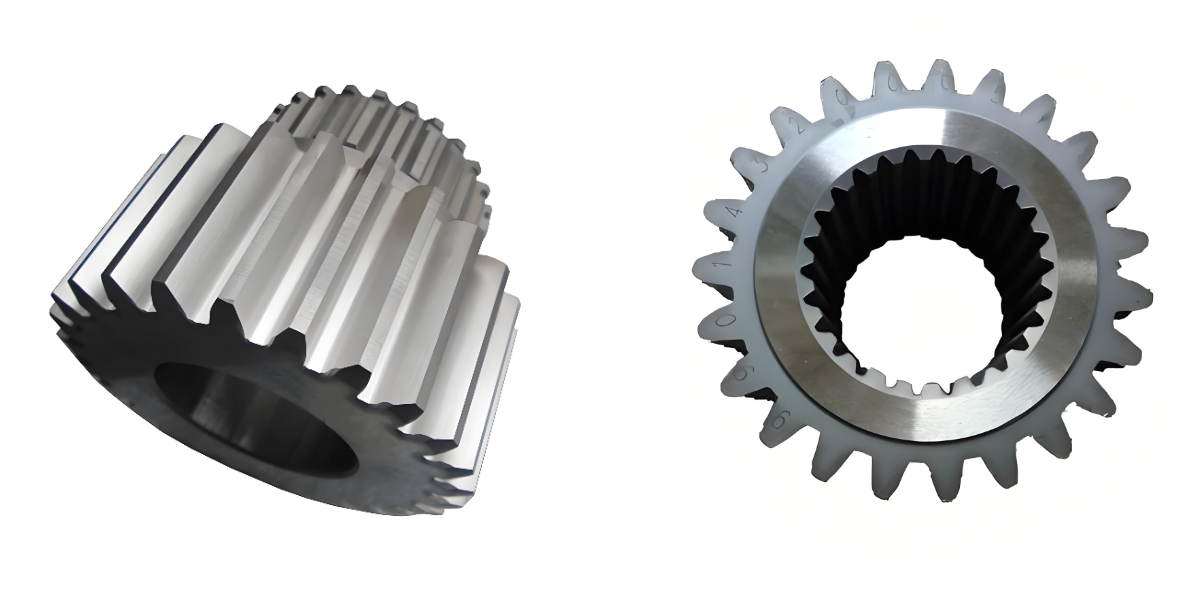

In the field of mechanical transmission, Planetary Gears, with their compact structure, high transmission efficiency and large transmission ratio, have become the core transmission components of many industrial equipment and transportation vehicles. A complete Planetary Gears system is composed of four key components They are respectively the Sun gears that provide power input, the Planet Gears that rotate around the Sun gears, the Ring Gear that serves to fix and support, and the Carrier that connects the planet gears. These four major components work in coordination. They jointly achieve the transmission and speed change of power, and the whole composed of them is also called a planetary gear system or a Planetary Gear Set.

I. The main Types of Planetary Gears

According to different application scenarios and transmission requirements, Planetary Gears can be divided into many types. The combination methods and working principles of Sun gears, Planet Gears, Ring Gear and Carrier of each type are slightly different.

Single-stage Planetary Gears: This is the most basic type of planetary gears, consisting of only one set of Sun gears, Planet Gears, Ring Gear and Carrier. Its structure is simple and the transmission ratio is fixed. It is often used in equipment with no complex transmission requirements, such as the reduction mechanism of small motors. In a single-stage planetary gear system, power is input from Sun gears and transmitted to Carrier or Ring Gear Output via Planet Gears to achieve deceleration or acceleration functions. The corresponding output mode may be Shaft Output.

Multi-stage Planetary Gears: When a larger transmission ratio or more precise speed change control is required, multi-stage planetary gears come into play. It consists of multiple Planetary Gear sets connected in series or parallel. The Carrier or Ring Gear of the previous stage can serve as the power input component of the subsequent stage. This type of planetary gearbox is widely used in heavy machinery and wind power equipment. Its Spindle Output can stably output large torque, meeting the high-intensity working requirements of the equipment.

Compound Planetary Gears: The structure of compound planetary gears is more complex. They usually consist of two or more Sun gears and mesh with Ring gears through different Planet Gears, enabling the switching of various transmission ratios. It is relatively common in the automatic transmission of automobiles. It can flexibly adjust the transmission state according to the vehicle's driving speed and load changes to ensure the smoothness and power of driving. Meanwhile, the transmission links related to its Wheel Drive also rely on the precise coordination of compound planetary gears.

Ii. The wide range of Applications of Planetary Gears

Planetary Gears, with its outstanding transmission performance, plays an irreplaceable role in multiple industries. Different application scenarios correspond to different planetary gear system designs and planetary gearbox configurations.

In the automotive industry, Planetary Gears are a core component of automatic transmissions in the transmission system of automobiles. Sun gears receives the power transmitted by the engine, Planet Gears rotates around it and drives the Carrier or Ring Gear to move, and then transmits the power to the Wheel Drive system through Shaft Output to achieve acceleration, deceleration and reversing of the vehicle. In addition, the power coupling mechanism of hybrid vehicles often adopts Planetary Gear Set to achieve efficient coordination between fuel power and electric power.

In the field of industrial machinery: In machine tool equipment, Planetary Gears are often used in Spindle drive systems. Through the variable speed function of planetary gearboxes, the spindle speed can be adjusted to meet different processing requirements. The precision of its Spindle Output directly affects the quality of the processed parts. Meanwhile, in heavy machinery such as cranes and conveyors, Planetary Gears can provide high-torque transmission, ensuring stable operation of the equipment when carrying heavy loads. At this time, the fixation of the Ring Gear and the load-bearing capacity of the Carrier play a crucial role.

Aerospace and new energy fields In aerospace equipment, such as the engine accessory transmission system of aircraft, Planetary Gears, with its compact structure and high reliability, can achieve efficient power transmission in a limited space. The high-precision meshing of Sun gears and Planet Gears can ensure the stable operation of the equipment under extreme working conditions. In the field of new energy, the gearboxes of wind power equipment adopt Planetary Gear Set, which can convert the low-speed rotation of the wind turbine into the high-speed rotation required by the generator. In the photovoltaic tracking system, the Angle of the photovoltaic panels is also adjusted through the planetary gear System to improve the utilization rate of solar energy.

Iii. Processing Techniques of Planetary Gears

The processing of Planetary Gears has extremely high requirements for precision. Each link directly affects the performance and fit accuracy of Sun gears, Planet Gears, Ring Gear and Carrier. This further determines the transmission efficiency and service life of the planetary gear system

Gear blank manufacturing: Firstly, according to the size and material requirements of Planetary Gears, gear blanks are made by forging or casting processes. Forging process can enhance the metal density and mechanical properties of the blank, and is suitable for Sun gears and Planet Gears that withstand large torques. The casting process is applicable to the Carrier and Ring Gear with complex structures, which can reduce manufacturing costs.

Gear processing: For Sun gears and Planet Gears, the tooth profiles need to be processed through processes such as turning, hobbing and shaping. The gear hobbing process can efficiently produce high-precision involute tooth profiles, ensuring the meshing accuracy of Sun gears and Planet Gears. The Gear shaping process is applicable to processing the tooth profile of the internal teeth of the internal gear Ring. After processing is completed, heat treatment such as carburizing and quenching is still required to enhance the hardness and wear resistance of the Gears and extend the service life of Planetary Gears.

Assembly and Inspection: During the assembly process of Planetary Gear Set, Sun gears, Planet Gears, Ring Gear and Carrier need to be precisely assembled to ensure that the coaxiality and meshing clearance of each component meet the design requirements. After assembly is completed, performance tests are conducted on the planetary gearbox, including transmission efficiency tests, noise tests, torque tests, etc. At the same time, the accuracy of Shaft Output and Spindle Output is checked to ensure that the planetary gear system can meet the actual application requirements.

To sum up, Planetary Gears, as an efficient transmission component, has Sun gears, Planet Gears, Ring Gear and Carrier each performing their own duties in its structure. Different types of Planetary Gears and planetary gearboxes are suitable for different application scenarios, and precise processing techniques are the key to ensuring their performance. With the continuous development of industrial technology, the application of Planetary Gears in more fields will continue to expand, providing strong support for the upgrading and optimization of mechanical transmission systems.