Construction Machinery Seat Ring Selection Guide: Forging Technology Empowers, No Leakage Even Under Heavy-Duty Conditions

Construction Machinery Seat Ring Selection Guide: Forging Technology Empowers, No Leakage Even Under Heavy-Duty Conditions

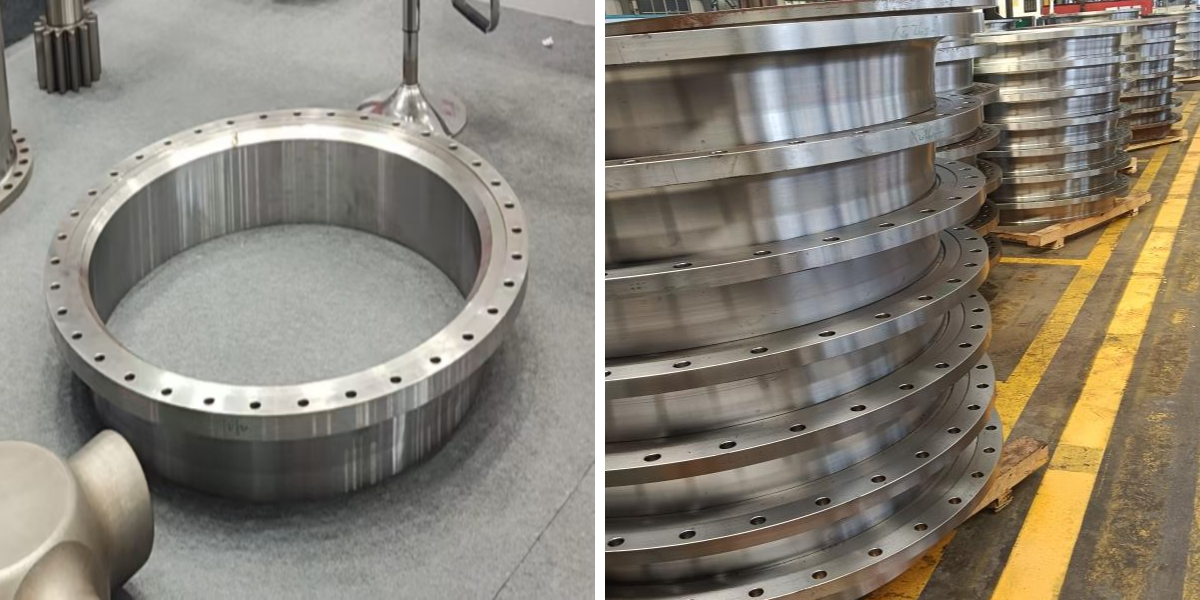

In the core parts such as the hydraulic system and valve groups of construction machinery, the seat ring is a key component that determines the sealing performance and operational stability. Especially in heavy-load operation scenarios of equipment such as excavators, cranes and loaders, seat ring needs to withstand high pressure, high-frequency friction and erosion of harsh working conditions. Its quality is directly related to whether the equipment leaks and the level of maintenance costs. The forging process, with its ultimate optimization of material properties, has become the core manufacturing method for high-end seat rings and is also the mainstream technical choice in the field of excavator forgings. This article will create a practical guide for selecting seat rings in construction machinery from three dimensions: core elements of selection, advantages of forging processes, and compatibility skills for equipment such as excavators. It aims to help industry practitioners accurately avoid pitfalls and improve the operational efficiency of equipment.

I. When selecting the model, clarify the core function and working condition requirements of the seat ring for construction machinery

1.The core functional positioning of seat ring

Seat ring, as a key sealing component of hydraulic valves and control valves in construction machinery, mainly undertakes three core responsibilities:

Sealing and leak prevention: Block the leakage of hydraulic oil, coolant and other media, ensure the stability of system pressure, and avoid power loss and equipment failure caused by leakage.

Wear-resistant and anti-wear: It can withstand the high-frequency relative motion friction between the valve core and the valve seat, reducing component wear and extending the overall service life of the valve group.

Pressure resistance and impact resistance: During heavy-load operations (such as excavators digging hard rock and cranes lifting heavy objects), it can withstand instantaneous high-pressure impacts and maintain structural integrity.

2. The harsh working conditions challenges of the seat ring of construction machinery

Construction machinery mostly operates in complex environments such as mines and infrastructure construction sites. seat ring needs to cope with multiple tests:

Heavy load and high pressure: The pressure of the hydraulic system can reach tens of megapascals, and the seat ring needs to withstand continuous high-pressure loads.

Environmental erosion: Dust, sand, rainwater and other substances can easily enter the sealing surface, accelerating wear and corrosion.

Temperature fluctuation: The temperature in the working scene varies greatly (-20℃ to 80℃), and the material is required to have good temperature adaptability.

High-frequency reciprocating: The frequent opening and closing of the valve core and seat ring impose extremely high requirements on wear resistance.

These working condition characteristics determine that the seat ring must have the core properties of high strength, high hardness, wear resistance and corrosion resistance, and the forging process is precisely the key to meeting these requirements.

Ii. Forging Process: The "Upgrade Code" for the Performance of seat Rings in Construction Machinery

1.Why is forging the preferred process for seat ring?

Compared with processes such as casting and machining, forging has an irreplaceable advantage in improving the performance of seat ring:

Material densification: During the forging process, the metal billet undergoes plastic deformation under high temperature and high pressure, and the grains are refined and densified, completely eliminating internal defects such as porosity, porosity, and segregation. This increases the tensile strength and yield strength of the seat ring by more than 30%, making it suitable for heavy-load and high-pressure working conditions.

Wear-resistant and impact-resistant: The forged seat ring has significantly enhanced impact toughness, capable of withstanding the instantaneous impact during the operation of construction machinery. Meanwhile, its surface hardness can reach over HRC50, and its wear resistance far exceeds that of castings.

Structural integrity: It is formed by integral forging without welding seams, avoiding the risk of seal failure caused by welding defects. It is particularly suitable for the manufacturing of seat rings for high-frequency operation equipment such as excavators.

High dimensional accuracy: Precisely formed through die forging process, only a small amount of fine processing is required subsequently to meet the high-precision requirements of the sealing surface, ensuring a perfect fit with the valve core and reducing the risk of leakage.

2. Core Application of forging process in Excavator forgings

As a core category of construction machinery, the key components of excavators such as the hydraulic valve seat ring and valve core all belong to the important components of excavator forgings. Due to the frequent opening and closing of the valve group and the large load fluctuation during the operation of the excavator, the reliability requirement for the seat ring is extremely high:

The main control valve seat ring of the excavator's hydraulic system is forged from high-strength alloy steels such as 42CrMo and 35CrNiMo. After quenching and tempering treatment, it can not only withstand high pressure but also resist the high-frequency friction of the valve core.

The seat ring of the control valve of the excavator boom and bucket arm is further enhanced in hardness and wear resistance through forging and surface nitriding treatment, which extends the sealing life by 2-3 times and reduces the maintenance cost of frequent replacement on the construction site.

Iii. A Comprehensive Guide to seat ring Selection for Construction Machinery: 5 Core Elements + Scenario Adaptation

Core selection element 1: Material matching (forged materials are preferred)

The material of the seat ring directly determines its upper performance limit. The mainstream material selection in combination with the forging process is as follows:

Alloy steel forging (recommended) : 42CrMo, 35CrNiMo, etc., suitable for heavy-load and high-frequency working conditions, such as the main control valve seat ring of excavators and cranes, with the comprehensive advantages of high strength, high wear resistance and impact resistance;

Stainless steel forging: 304, 316L, etc., suitable for corrosive environments (such as coastal infrastructure, chemical construction sites), preventing salt spray and chemical medium erosion;

Copper alloy forging: tin bronze, aluminum bronze, etc., which have good self-lubricating properties, are suitable for low-speed and light-load working conditions, such as the auxiliary valve seat ring of loaders.

Selection suggestion: Give priority to forging materials and avoid casting materials (which are prone to sand holes, cracks and have poor sealing reliability).

Core selection element 2: Process verification (Verify the forging mark)

Check the process certificate: Request the supplier to provide the forging process report to confirm that the seat ring is integrally forged rather than cast or welded parts;

Observe the appearance and structure: The surface of the forged seat ring has no casting pores or burrs, and the sealing surface is smooth and flat. Internal cracks can be detected through magnetic particle inspection.

Check the dimensional accuracy: The seat ring forged and finely machined has a dimensional tolerance that can be controlled within ±0.01mm, ensuring that the fit clearance with the valve core is between 0.005 and 0.01mm, and guaranteeing the sealing effect.

Core selection element 3: Adaptation to working conditions

Heavy-load and high-pressure scenarios (excavator excavation, crane hoisting) : Select seat ring made of alloy steel forging + surface hardening treatment, with hardness ≥HRC55 and compressive strength ≥800MPa;

Corrosive environment (seaside, chemical construction site) : Stainless steel forged seat ring, combined with fluororubber sealing parts to enhance corrosion resistance;

High-frequency operation scenarios (mining excavators, port cranes) : seat rings with forged and laser-cladding wear-resistant layers further enhance wear resistance and extend service life.

Core selection element 4: Brand and quality Assurance

Give priority to choosing manufacturers that focus on excavator forgings or construction machinery forgings, as their forging processes are more mature and have stronger adaptability.

Verify product certification: Ensure that seat ring has passed the ISO9001 quality system certification, and key indicators comply with industry standards such as GB/T and ISO;

Reference customer case: Choose a supplier with experience in supporting mainstream equipment manufacturers such as excavators and cranes to ensure better quality.

Core selection element 5: Installation and maintenance compatibility

When selecting the model, it is necessary to confirm the installation method of the seat ring (such as interference fit, threaded connection, etc.) and precisely match it with the valve group of the equipment.

Give priority to the modular design of the forged seat ring, which is easy to disassemble and replace, reducing the difficulty of maintenance on the construction site.

Pay attention to after-sales service: Choose suppliers that offer technical support and a long warranty period (usually 1-2 years) to deal with sudden malfunctions.

IV. Common Selection Pitfalls to Avoid: Don't Repeat These Mistakes!

Misconception 1: Only focusing on the price while neglecting the forging process

Some purchasers choose to cast seat rings to control costs. Although the initial price is relatively low, they are prone to leakage and cracking under heavy load conditions and may need to be replaced within half a year, which instead increases the overall cost. Suggestion: For heavy-load scenarios, forged seat rings must be chosen as they are more cost-effective in terms of long-term usage costs.

Misconception 2: The harder the material, the better

Excessive pursuit of high hardness may lead to insufficient toughness of the seat ring and its fracture under instantaneous impact. The correct approach is to select forging materials with a balanced "hardness + toughness" based on the working conditions. For instance, after quenching and tempering treatment, 42CrMo alloy steel can achieve both hardness and toughness.

Misconception 3: The universal seat ring is compatible with all devices

The valve group structures and pressure ratings of different construction machinery vary greatly. For example, the sealing requirements of the main control valve seat ring of excavators are different from those of loaders. Suggestion: Provide the equipment model and valve group parameters, and select the customized forged seat ring to avoid seal failure caused by the universal type.

Misconception 4: Neglecting surface treatment processes

The surface treatment (nitriding, laser cladding, chromium plating, etc.) of the forged seat ring directly affects its wear resistance and corrosion resistance. For example, when excavators are operating in mines, the seat ring needs to be nitrided to enhance its surface hardness; otherwise, it is prone to wear by dust.

V. Industry Development Trends: The Technological Upgrade Direction of Forging seat Rings

1. Material upgrade: The integration of new alloys and forging processes

By adopting new materials such as high-strength aluminum alloy and composite materials, combined with precision forging technology, the weight of the seat ring is reduced while ensuring strength, the energy consumption of the hydraulic system is lowered, and it is in line with the trend of lightweighting in construction machinery.

2. Digitalization of process: Full-process control of forging

The introduction of digital twins and intelligent forging equipment enables real-time monitoring of parameters such as temperature and pressure during the seat ring forging process, enhancing product consistency and performance stability. Particularly in the field of Excavator forgings, digital forging has become the core competitiveness of high-end products.

3. Integrated design: seat ring and valve core are integrally forged

In the future, the seat ring and the valve core may adopt an integrated forging process to reduce assembly steps, improve sealing accuracy and structural stability, and further reduce the risk of leakage.

4. Intelligent monitoring: Integrated sensor technology

Temperature and wear sensors are embedded in the forged seat ring to monitor the sealing status in real time. Data is transmitted through the Internet of Things to achieve predictive maintenance and reduce equipment downtime.

Summary

The core of selecting a seat ring for construction machinery is to choose a product with "forging process + compatible material + precise matching" based on the working conditions and requirements. The forging process, by densifying the material and enhancing its wear resistance and impact resistance, has become an inevitable choice for seat rings under heavy-duty conditions. Especially in the field of excavator forgings, forged seat rings have become the standard for valve group seals in high-end excavators.

Through the selection guide in this article, it is hoped that practitioners in the construction machinery industry can avoid misunderstandings and accurately choose the suitable seat ring to achieve the usage goal of "no leakage under heavy load, long service life due to wear resistance, and low maintenance cost". In the future, with the digitalization of forging technology and the upgrading of materials, seat ring will further enhance its performance, providing more reliable sealing guarantees for the efficient and stable operation of construction machinery.