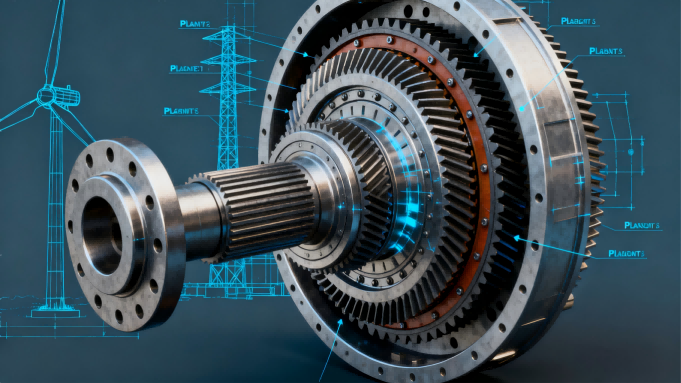

Planetary Carrier - Industrialize Wind Power: The core of wind power transmission, empowering the large-scale development of green energy

Planetary Carrier - Industrialize Wind Power: The core of wind power transmission, empowering the large-scale development of green energy

Driven by the global "dual carbon" goals, wind power, as a core pillar of clean energy, is accelerating its iteration towards large-scale, high-power and domestic production. The planetary carrier, as the core load-bearing and power transmission component of the wind turbine transmission system, its design accuracy, manufacturing process and structural reliability directly determine the power generation efficiency, operational life and stability of the wind turbine. It is a key core component that promotes the industrialization and scale development of the wind power industry. This article will comprehensively analyze the core value, technical characteristics, manufacturing processes and industry development trends of planetary carriers in the wind power field, to help understand their supporting role in the industrialization of wind power.

I. Core Definition: Planet Carrier - The "Power Center" of Wind Power Transmission System

1. Component essence and functional positioning

The planetary carrier is the core skeleton of the planetary gear transmission system, mainly used to support the planetary gear shaft, transmit torque, and coordinate the meshing motion of the sun gear, planetary gears and internal gear rings, achieving deceleration and torque increase or speed increase and torque reduction of power. In a wind turbine generator set, the planetary carrier is integrated into the main gearbox, receiving the wind energy captured by the wind turbine (low speed and high torque), and transmitting the power to the generator through gear meshing, completing the conversion of "wind energy - mechanical energy - electrical energy". It is a key power hub connecting the wind turbine and the generator.

2. The core mission of the wind power planet carrier

Wind turbine generators are constantly exposed to complex outdoor environments (such as strong winds, temperature differences, vibrations, salt spray, etc.), and their single-unit capacity is constantly increasing (from megawatt level to 15MW + ultra-large capacity breakthrough). The planetary carrier needs to undertake three core missions:

Bear heavy loads: Withstand the huge torque and impact loads transmitted by the wind turbine to ensure that the structure does not deform or break.

Precision transmission: Ensure the installation accuracy and rotational stability of planetary gear shafts, reduce meshing errors and energy loss;

Fatigue and corrosion resistance: Withstand long-term alternating loads and harsh environmental erosion, extending the service life of the gearbox and even the entire machine.

Ii. Technical Characteristics of the wind power planetary carrier: It meets the core requirements of wind power industrialization

The industrialization development of the wind power industry has put forward strict requirements for the standardization, high performance and high reliability of core components. As a key component, the technical characteristics of the planetary carrier must fully match the requirements of large-scale application of wind power:

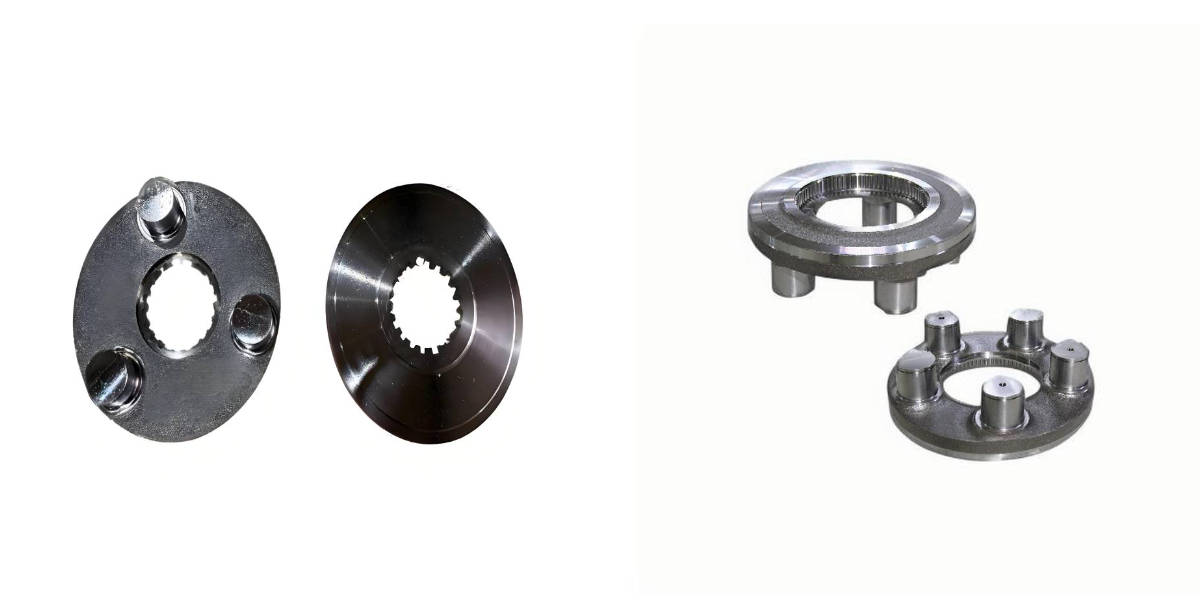

1. Structural design: Modularization and lightweight are taken into account

Modular design: For wind turbines of different power levels (2MW, 5MW, 10MW+), the planetary carrier adopts a modular structure, which can quickly adapt to different gearbox models, reduce design and manufacturing costs, and facilitate the standardized production of wind power equipment.

Lightweight optimization: Through finite element analysis (FEA), the structural topology is optimized. Thickening is adopted in key load-bearing parts, while hollow or hollowed-out structures are used in non-load-bearing parts. Under the premise of ensuring strength, the weight is reduced, the load on the wind turbine and gearbox is lowered, and the overall efficiency of the machine is improved.

High-precision interface: The dimensional tolerance and positional tolerance of the planetary gear shaft installation holes need to be controlled at the micrometer level to ensure the precise meshing of the planetary gears with the sun gear and the internal gear ring, reducing operating noise and wear.

2. Material selection: Equal emphasis on high strength and fatigue resistance

The wind power planetary carrier needs to select alloy structural steel with high strength, high toughness and fatigue resistance. Common materials include 42CrMo, 35CrNiMo, 20CrMnTi, etc. These materials have the following advantages:

It has high tensile strength and yield strength, and can withstand torque loads of hundreds of kilonewtons.

It has excellent impact toughness and can withstand the instantaneous load fluctuations caused by strong wind impacts.

It has strong fatigue resistance, can withstand long-term alternating loads, and prevent the occurrence of fatigue cracks.

The hardness and wear resistance can be further enhanced through heat treatment, meeting the design life requirement of over 20 years for wind power.

3. Performance Requirements: Extreme environmental adaptability and long service life guarantee

Weather resistance: The surface has undergone anti-rust and anti-corrosion treatments (such as nitriding, spraying, and electrophoresis), which can adapt to salt spray corrosion in offshore wind power and high and low temperature differences (-40℃ to 60℃) in onshore wind power.

Stability: During operation, the vibration amplitude is small and the noise is low, ensuring smooth transmission of the gearbox.

Long service life: The design life should be synchronized with the entire wind turbine (20 to 25 years), reducing operation and maintenance costs and downtime losses, and supporting the long-term stable returns of wind power projects.

Iii. Core Manufacturing Process: Forging the "Industrial Quality" of Wind Power Planetary Carriers

The manufacturing process of the wind power planetary carrier directly determines its performance. It needs to go through multiple precise procedures to ensure consistency and reliability requirements for industrial production.

Forging process: Lays the foundation of strength

Planetary carrier blanks are mostly manufactured by die forging or free forging processes:

By subjecting metal billets to plastic deformation through high temperature and high pressure, the grains are refined, defects such as pores and porosity are eliminated, and the density and mechanical properties of the material are enhanced.

For large-scale wind power planetary carriers (with diameters of over 3 meters), large-scale CNC die forging equipment is adopted to ensure uniform structure and precise dimensions of the blanks, laying a foundation for subsequent processing.

2. Mechanical processing: Ensuring the core of precision

Rough machining: Contour processing is carried out using large CNC lathes and milling machines to remove excess allowances and initially form the shape.

Precision machining: Through five-axis linkage machining centers and horizontal machining centers, key parts such as installation holes, end faces, and connection interfaces are precisely machined to ensure that dimensional tolerances and positional tolerances meet the design requirements.

Hole system processing: The installation holes of the planetary gear shafts are processed by honing, reaming and other techniques to enhance the surface roughness and cylindricity, ensuring the rotational flexibility of the planetary shafts.

3. Heat treatment process: Optimize performance indicators

Quenching and tempering treatment (quenching + high-temperature tempering) : Enhance the comprehensive mechanical properties of the material, taking into account both strength and toughness.

Surface hardening treatment: Nitriding, high-frequency quenching and other treatments are carried out on the easily worn parts such as the gear meshing surface and installation end face of the planet carrier to enhance surface hardness and wear resistance.

Stress relief annealing: It eliminates the internal stress generated during processing to prevent deformation or cracking caused by stress release during use.

4. Inspection and Quality Control: The "Lifeline" of Industrial Production

Dimensional inspection: Precision equipment such as three-coordinate measuring machines and laser rangefinders are used to conduct 100% inspection of key dimensions to ensure batch consistency.

Non-destructive testing: By using techniques such as ultrasonic testing (UT), magnetic particle testing (MT), and penetrant testing (PT), internal cracks, inclusions and other defects are detected.

Performance testing: Torque testing, fatigue testing, corrosion resistance testing, etc. are conducted on the finished products to verify their actual performance in use and ensure that they meet the strict requirements of industrial wind power applications.

Iv. The Core Enabling role of planetary carriers in the Industrialization of Wind Power

The core of wind power industrialization is to achieve "large-scale production, standardized supply, low-cost operation and maintenance, and highly stable operation". The planetary carrier empowers this process from multiple dimensions through its technological upgrade and process optimization:

1. Support the large-scale development of fans

As the single-unit capacity of wind power has broken through from 3MW to over 10MW, the diameter of the wind turbine and the torque load have grown exponentially, putting forward higher requirements for the load-bearing capacity and structural dimensions of the planetary carrier. The research and development and mass production of large-scale planetary carriers have solved the transmission bottleneck of ultra-high power wind turbines, promoting the development of wind power equipment towards higher efficiency and lower cost per kilowatt-hour, and providing core support for the construction of large-scale wind farms.

2. Promote domestic substitution and supply chain stability

Previously, high-end wind power planetary carriers mostly relied on imports, which restricted the independent and controllable development of the wind power industry. In recent years, domestic enterprises have achieved the mass production of planetary carriers through process upgrades and technological breakthroughs. This not only reduces the cost of equipment manufacturing but also ensures the stability of the supply chain, laying a foundation for the localization of wind power industrialization.

3. Reduce operation and maintenance costs and increase project returns

Highly reliable planetary carriers can reduce the probability of gearbox failures, lower the operation and maintenance frequency and downtime losses of wind farms. According to statistics, gearbox failure is one of the main cost sources for wind power operation and maintenance. The long-life design and stable performance of the planetary carrier can extend the maintenance cycle of the gearbox by more than 30%, significantly improving the return on investment of wind farms and promoting the sustainable industrialization development of the wind power industry.

4. Compatible with multi-scenario wind power applications

Whether it is a onshore plain or mountainous wind farm, or an offshore or intertidal wind farm, the planetary carrier can adapt to the environmental requirements of different scenarios through material optimization, structural adjustment and process upgrading. For instance, the offshore wind power planetary frame adopts anti-salt spray corrosion technology, and the mountain wind power planetary frame enhances its impact resistance, making it possible for the full coverage of wind power industrialization.

V. Industry Development Trends: The Synergistic Upgrade of planetary carriers and Wind Power Industrialization

With the transformation of the wind power industry towards "large-scale, intelligent and green", planetary carriers are also showing three major development trends:

1. Integrated design

In the future, planetary carriers will be integrated with components such as planetary gears, sun gears, and bearings in an integrated design, reducing assembly steps, enhancing transmission efficiency and structural stability, while lowering manufacturing costs and meeting the modular production requirements of wind power equipment.

2. Application of new materials and new processes

New materials: Develop lightweight materials such as high-strength aluminum alloys and composite materials to further reduce the weight of the planetary carrier and enhance the overall energy efficiency of the machine.

New process: Promote additive manufacturing (3D printing) technology to achieve integrated molding of complex structures, shorten the R&D cycle, and reduce the cost of small-batch customization;

Intelligent processing: By introducing industrial robots and digital twin technology, intelligent monitoring and quality traceability throughout the entire manufacturing process of planetary carriers are achieved, enhancing the precision and efficiency of industrial production.

3. Intelligent monitoring and predictive maintenance

Integrate sensors (temperature, vibration, and stress sensors) on the planetary shelf to monitor the operational status in real time. Through the Internet of Things and big data analysis, achieve fault early warning and predictive maintenance, reduce sudden downtime losses, assist in the intelligent operation and maintenance of wind farms, and promote the upgrade of wind power industrialization towards "smart energy".

Summary

The planetary carrier, as the core component of the transmission system of wind turbine generators, is the "cornerstone" of the industrial development of wind power. Its modular design, high-strength materials, precise manufacturing processes and high reliability performance support the large-scale, domestic and large-scale application of wind turbines, providing a key guarantee for cost reduction, efficiency improvement and independent control in the wind power industry.

With the continuous upgrading of the wind power industry, planetary carriers will constantly break through in new materials, new processes, and intelligence, deeply coordinating with the industrialization process of wind power, and contributing to the global energy transition towards a more efficient, stable, and sustainable direction. In the future, technological innovations in planetary carriers will continue to drive down the cost per kilowatt-hour of wind power, enabling clean energy to be more widely integrated into production and life, and injecting strong impetus into the realization of the "dual carbon" goals.